Soaping method of fiber dyed with reactive dyes

A reactive dye and soaping technology, which is applied in the field of fiber dyeing, can solve problems such as increased process cost, reduced fiber color fastness, and high energy consumption, and achieves the effects of saving process cost, reducing the number of washing times, and reducing overall energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Select the CF40 / 1 pure cotton yarn of the same yarn batch, arrange the following dye formula (Table 1) to carry out conventional pretreatment and dyeing, after the dyeing is finished, it is out of the vat, split into two vats on average, and use the post-treatment process of Comparative Example 1 and the vat respectively. The post-treatment process of Example 1 of the present invention was tested and compared.

[0034] Table 1

[0035] dye combination Dye dosage OWF reactive red 1 2.10% Active Yellow 1 1.51% Reactive Blue 1 3.25%

[0036] The post-processing flow is as follows:

[0037] (1) Post-treatment process of Comparative Example 1: washing with water (50°C×5min)→acid washing (50°C×5min)→soaping (98°C×10min+soaping agent)→soaping (98°C×10min+soaping agent )→soaping (98℃×10min+soaping agent)→water washing (80℃×5min)→water washing (80℃×5min)→water washing (80℃×5min)→water washing (60℃×5min);

[0038] (2) Post-treatment process of...

Embodiment 2

[0048] Select the CF40 / 1 pure cotton yarn of the same yarn batch, arrange the following dye formula (Table 3) to carry out conventional pretreatment and dyeing, after the dyeing is finished, it is out of the vat, split into two vats on average, and use the post-treatment process of Comparative Example 2 and the vat respectively. The post-treatment process of Example 2 of the present invention was tested and compared.

[0049] table 3

[0050] dye combination Dye dosage OWF Reactive Red 2 1.10% Active Yellow 2 1.51% Reactive Blue 2 4.25%

[0051] The post-processing flow is as follows:

[0052] (1) Post-treatment process of comparative example 2: washing with water (50°C×5min)→acid washing (50°C×5min)→soaping (98°C×10min+soaping agent)→soaping (98°C×10min+soaping agent )→soaping (98℃×10min+soaping agent)→water washing (80℃×5min)→water washing (80℃×5min)→water washing (80℃×5min)→water washing (60℃×5min);

[0053] (2) Post-treatment process of...

Embodiment 3

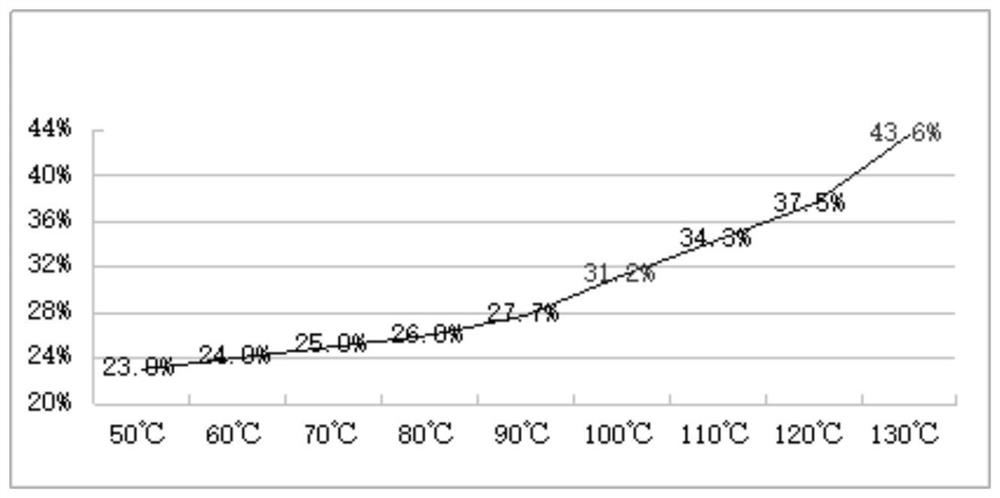

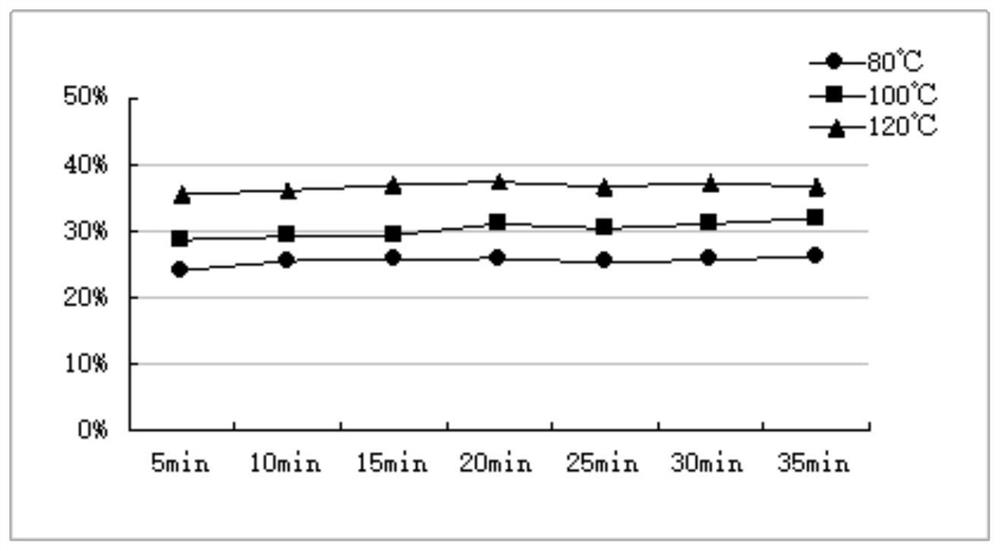

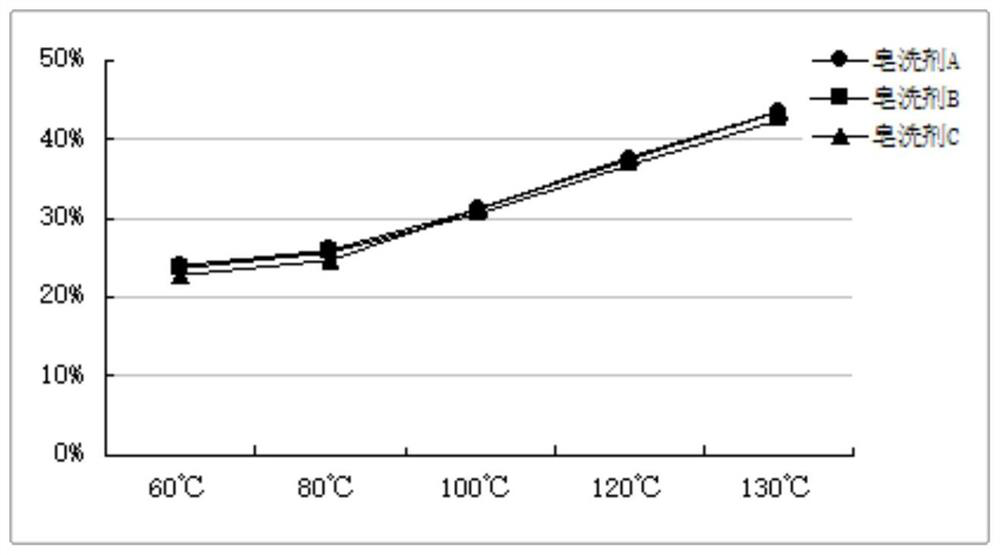

[0061]According to the same post-treatment process of embodiment 1, the reactive dye hydrolyzed dye wash-out effect and the impact of high soaping temperature on color fastness are studied under different soaping temperatures, different soaping times or different soaping agent conditions, the results are as follows Figure 1-3 and shown in Table 5.

[0062] table 5

[0063]

[0064] Depend on figure 1 It can be seen that as the soaping temperature increases, the wash-off rate gradually increases, and when the temperature rises above 110°C, the rate of increase increases greatly, and the wash-off rate between 110°C and 130°C is 34.3% to 43.6%. Compared with soaping at 100°C, the floating color removal rate is increased by 10-40%, and the floating color removal rate is significantly improved.

[0065] Depend on figure 2 It can be seen that with the increase of soaping time, there is little difference in the wash-off rate, which can be reasonably controlled to 5min-20min i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com