Turbulent flow energy-dissipating anti-scouring open caisson and construction method thereof

A construction method and anti-scouring technology, applied in caissons, infrastructure engineering, construction, etc., can solve the problems of increasing the difficulty and risk of caisson sinking construction, consuming manpower and material resources, and heavy workload, so as to reduce construction difficulty and save construction period , the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

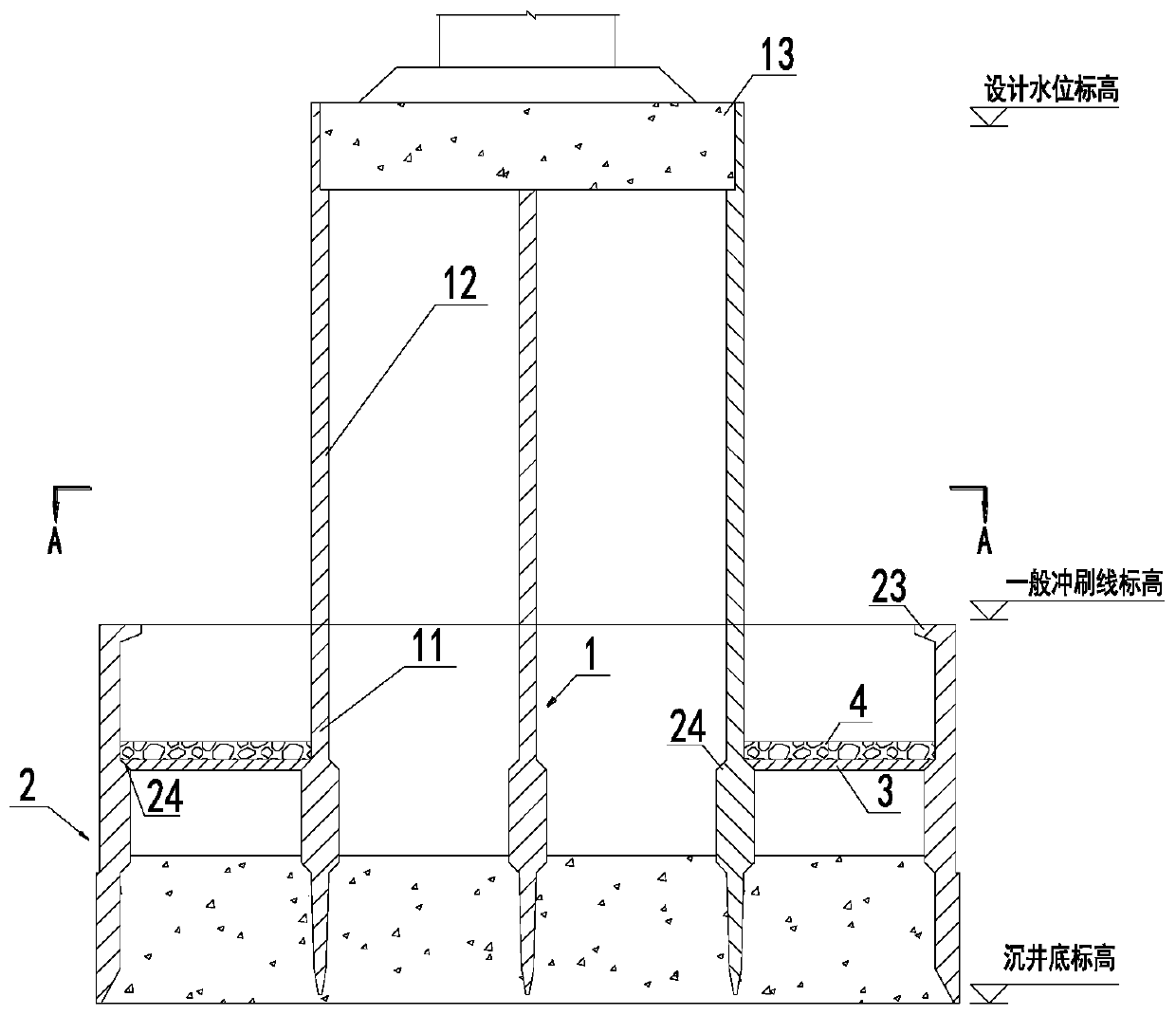

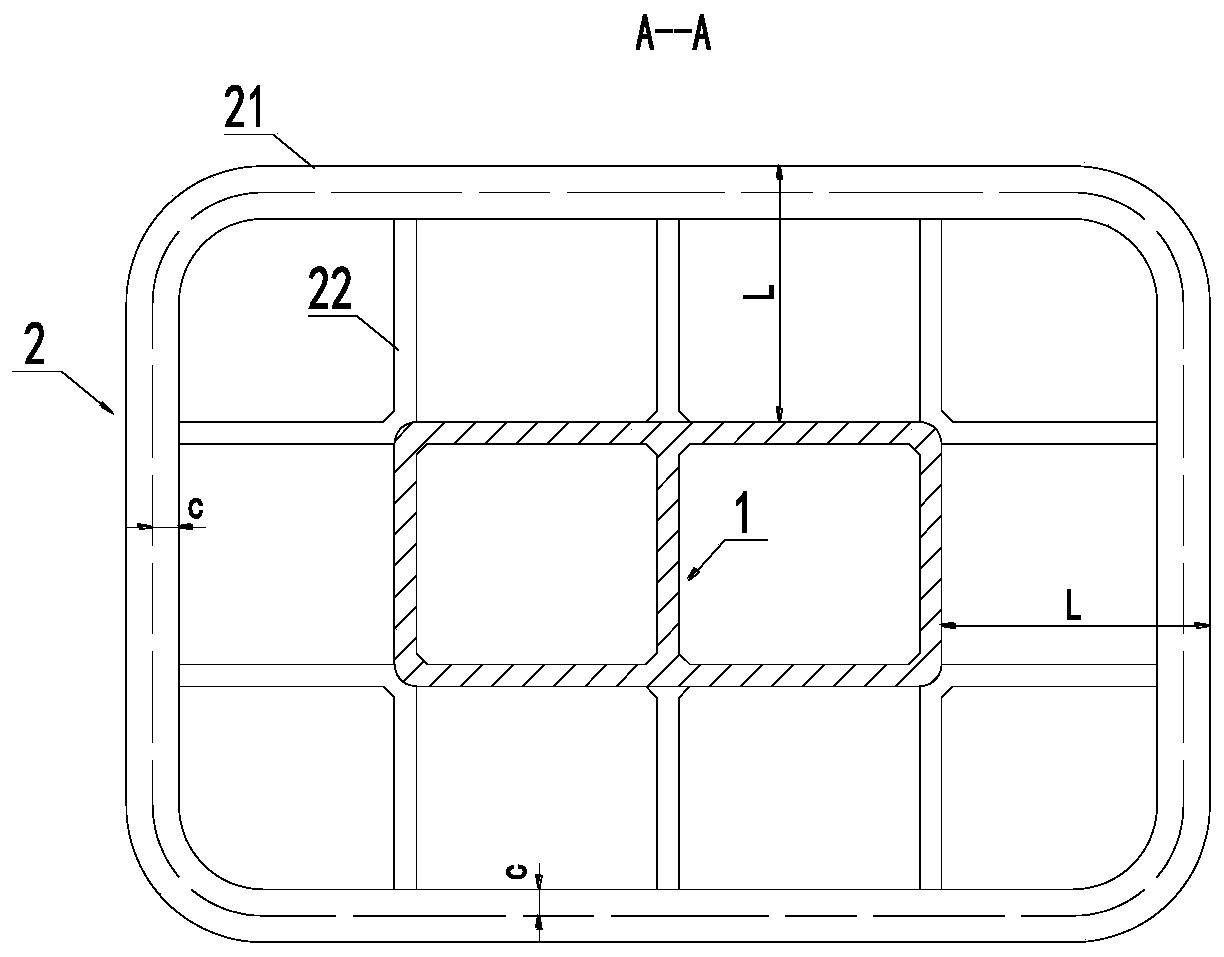

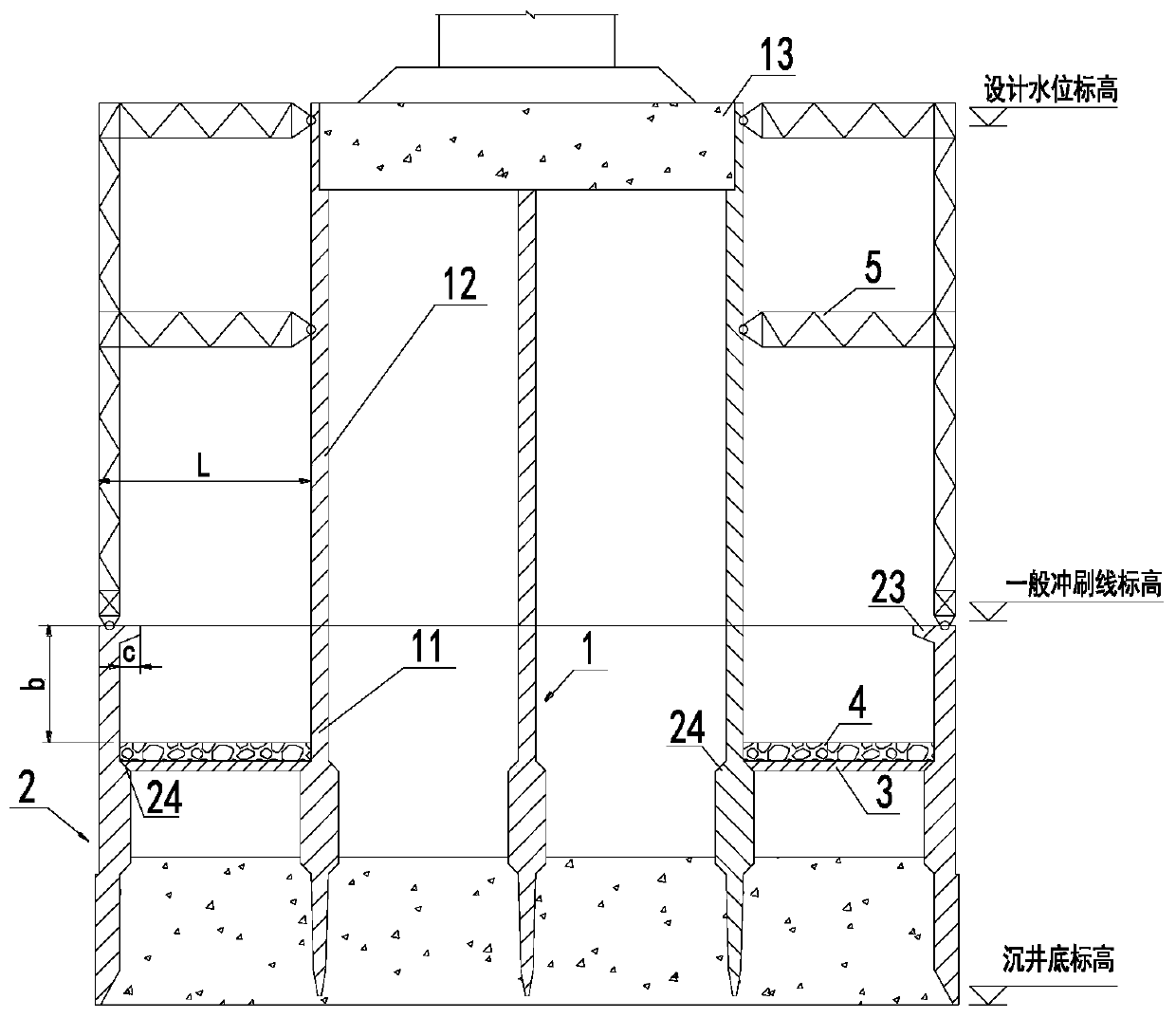

[0030] see figure 1 and figure 2 As shown, the embodiment of the present invention provides a flow-disturbing energy-consuming anti-scouring caisson, which is characterized in that it includes: The connected caisson bottom section 11 and caisson upper section 12 are provided with a top cover plate 13 on the caisson upper section 12 .

[0031] The expanded step well 2 is arranged along the outer periphery of the caisson bottom section 11, and the expanded bottom step well 2 includes the expanded bottom stepped well outer wall plate 21 and the expanded bottom stepped well inner wall plate 22 connected with the caisson bottom section 11 outer wall, and the expanded bottom stepped well The inner wall plate 22 divides the space between the outer wall plate 21 of the expanded bottom step well and the outer wall of the caisson bottom section 11 in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Equivalent diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com