Post-processor structure of detachable integrated urea nozzle

A post-processor and integrated urea technology, applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the disadvantages of generalization, integration, modularization, inability to observe post-processor crystallization at any time, vehicle nitrogen oxides Excessive faults and other problems, to achieve the effect of improving system integration, reducing system differences, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

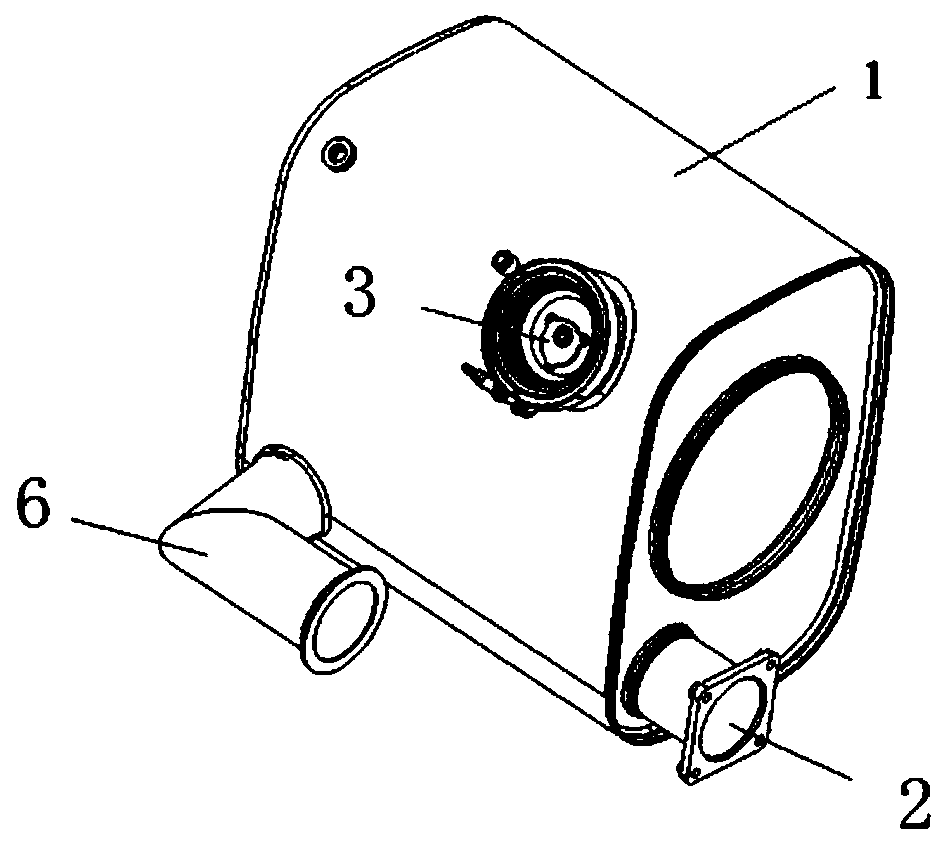

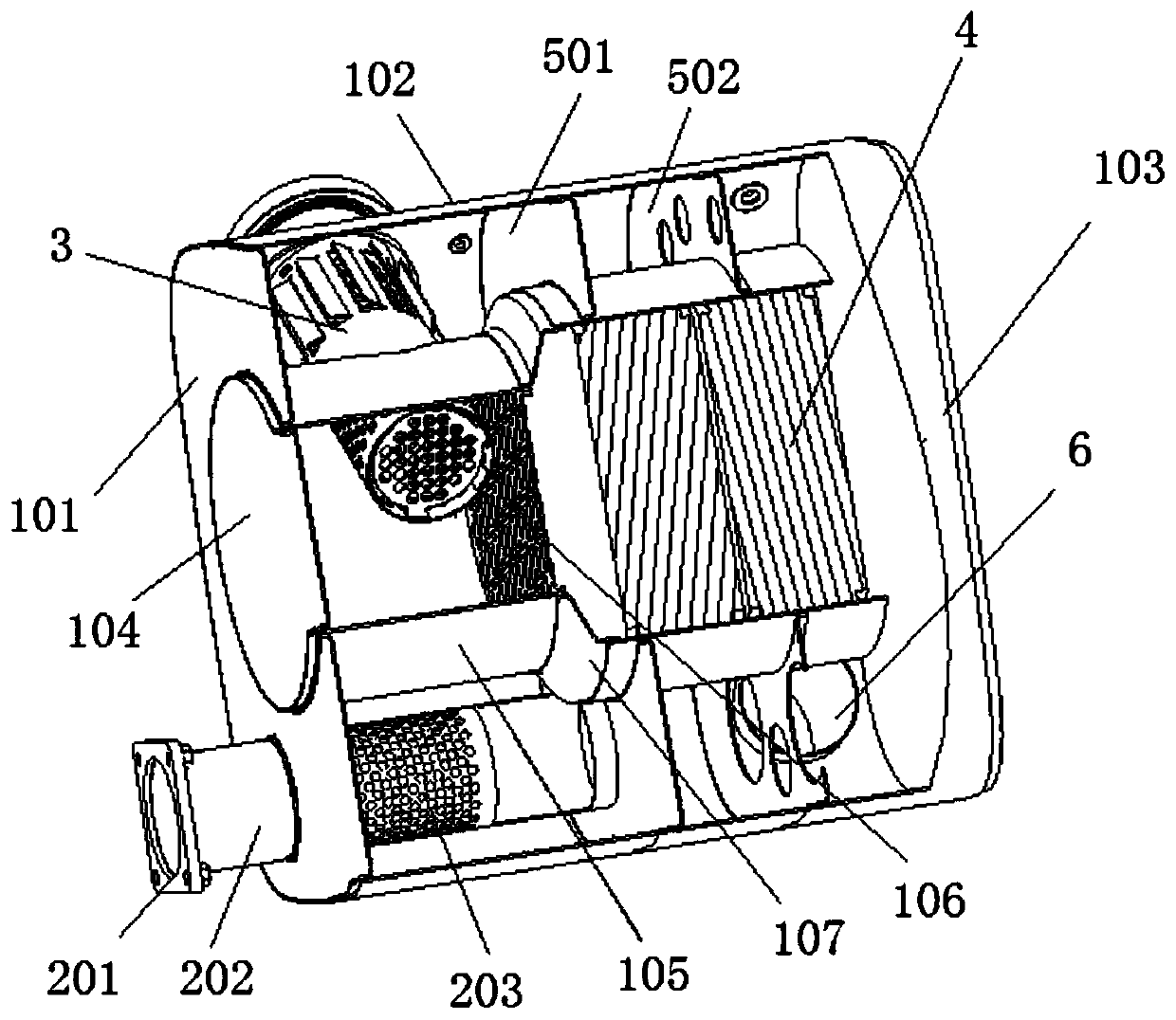

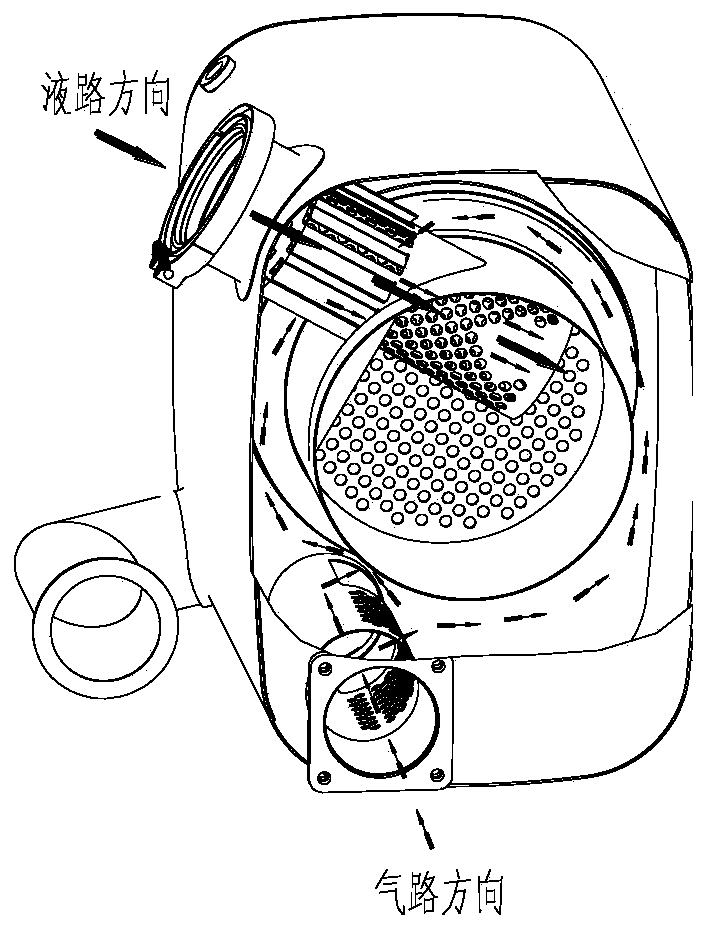

[0045] Such as figure 1 , figure 2 , image 3 As shown, the afterprocessor structure of the detachable integrated urea nozzle of the present invention is a series structure, including a postprocessor housing 1, an air inlet unit 2, a mixing unit 3, an SCR unit 4, a muffler unit 5 and an air outlet unit 6 ;

[0046] Such as figure 1 , 2 , 4, the after-processor housing 1 includes a welded front end cover 101, an outer shell 102, and a rear end cover 103; a cylindrical mixing chamber is provided in the after-processor housing 1; the mixing chamber The body includes a mixing chamber end cover 104, a mixing chamber shell 105, a mixing chamber porous end cover 106, and a fixed cone 107 welded and fixed together; Above: the mixing chamber casing 105 is located in the post-processor housing 1 , and its end is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com