Inertia measurement unit calibration system based on high-precision motion capture system

An inertial measurement unit and motion capture technology, applied in the field of indoor inertial navigation, can solve the problem of complex and long calibration process, and a calibration needs at least half an hour to an hour, etc., to achieve high-precision results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

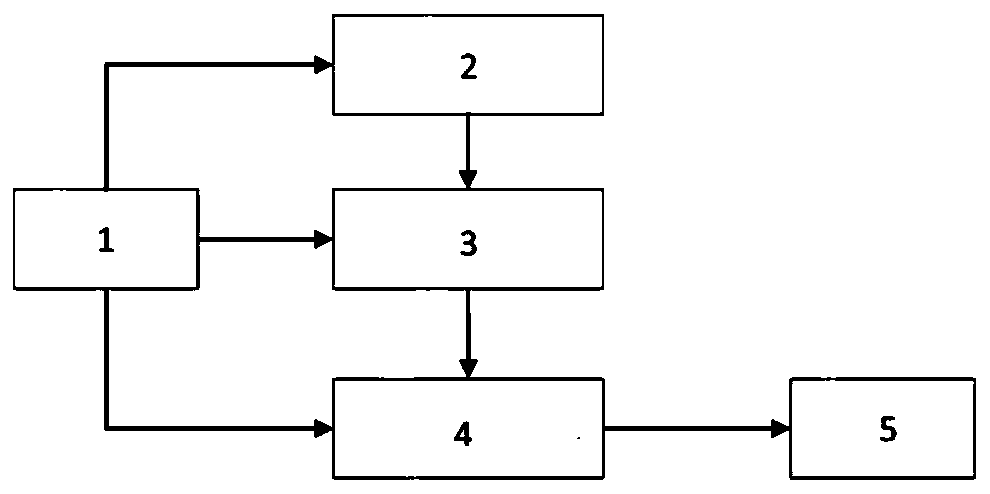

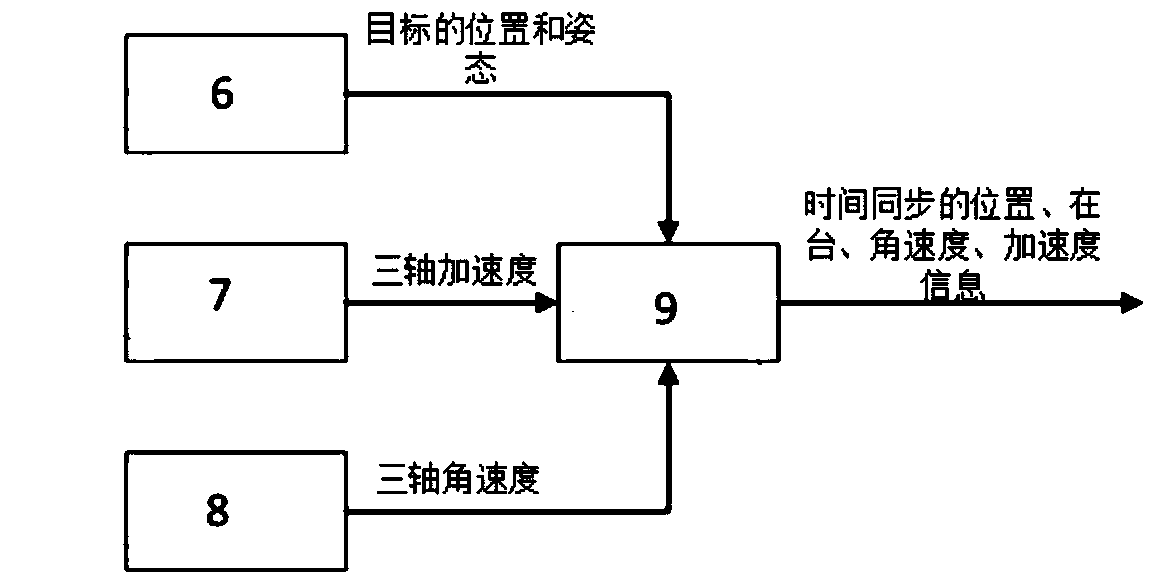

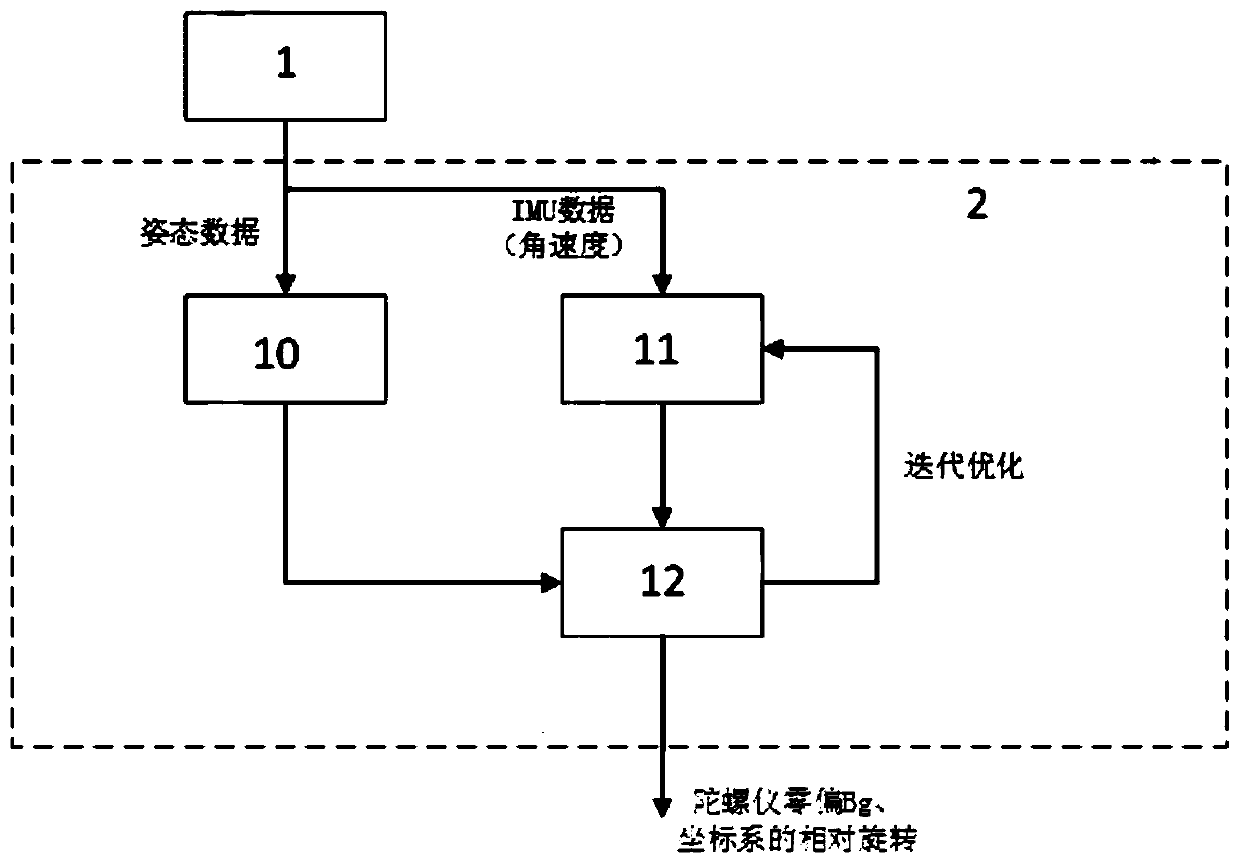

[0024] like figure 1 As shown, it is an inertial unit calibration system based on a high-precision motion capture system related to this embodiment, including: a data acquisition module 1, an attitude factor module 2, a velocity factor module 3, a position factor module 4 and an output module 5, wherein : The data acquisition module 1 is used to collect the position information and attitude information from the motion capture system, and the acceleration and angular velocity information from the inertial measurement unit; the attitude factor module 2 is connected to the data acquisition module 1 and optimizes the attitude factor, and calculates the gyroscope of the inertial measurement unit The relative rotation between the gyroscope zero bias parameter and multiple coordinate systems; the speed factor module 3 is connected with the data acquisition module 1 and the attitude factor module 2 respectively, and the relative rotation between the gyroscope zero bias parameter and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com