Flow control sealing mechanism and yarn hairiness detection method based on same

A technology of sealing mechanism and airflow control, applied in measuring devices, material analysis by optical means, instruments, etc., can solve the problems of poor measurement accuracy of hairiness quantity and length, high light source requirements, poor synchronization and stability, etc. The effect of blocking lodging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and examples.

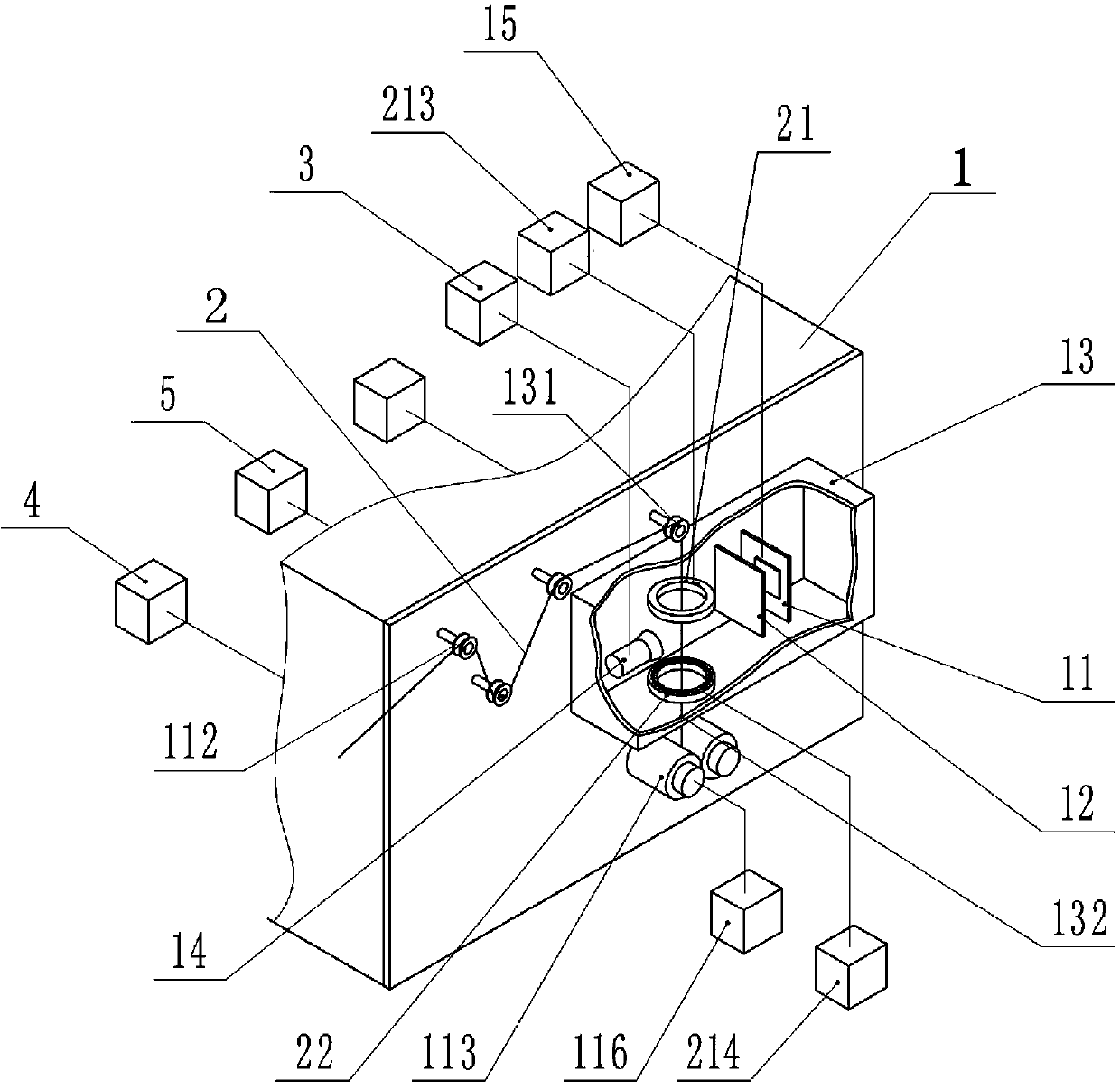

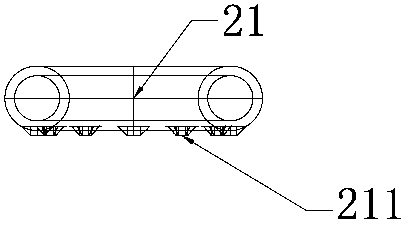

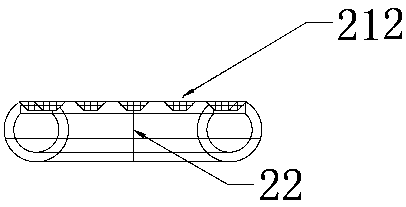

[0048] Such as figure 1 , the embodiment of the present invention comprises the frame 1 of yarn hairiness instrument, and several yarn guide wheels 112 are installed on the frame 1, and the end yarn guide wheel in the yarn guide wheel is used as positioning wheel 131, and this positioning wheel 131 is positioned at yarn. The top of the yarn pulling roller 113 of the hairiness meter. A shade 13 is provided between the positioning wheel 131 and the yarn pulling roller 113, and the specific setting method is to be fixedly installed on the frame 1. The yarn 2 passes through the positioning wheel 131 and passes through the upper and lower wall panels of the shade 13 and then enters the yarn pulling roller 113 , where the position passing through the lower wall panel is the positioning point 132 . The shading cover 13 is provided with an annular jet pipe 21 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com