Liquid fuel heat pipe reactor

A liquid fuel and reactor technology, applied in nuclear engineering and nuclear fields, can solve the problems of fuel layer deformation, local heating unevenness, etc., achieve the effect of simplifying the heat pipe structure, avoiding excessive power, and improving heat and power distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

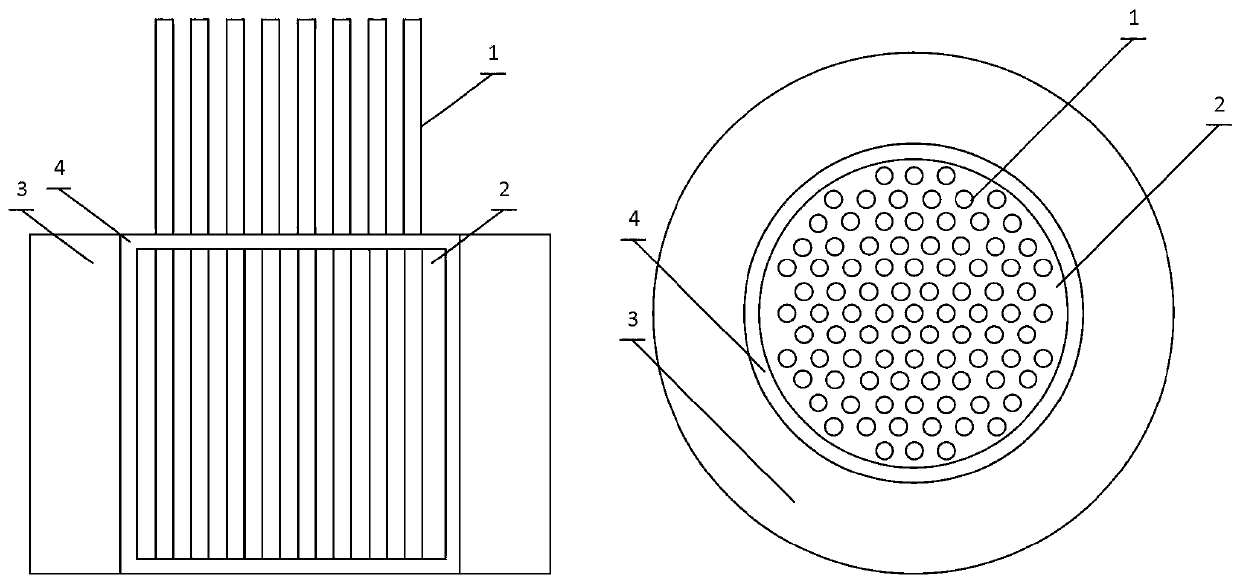

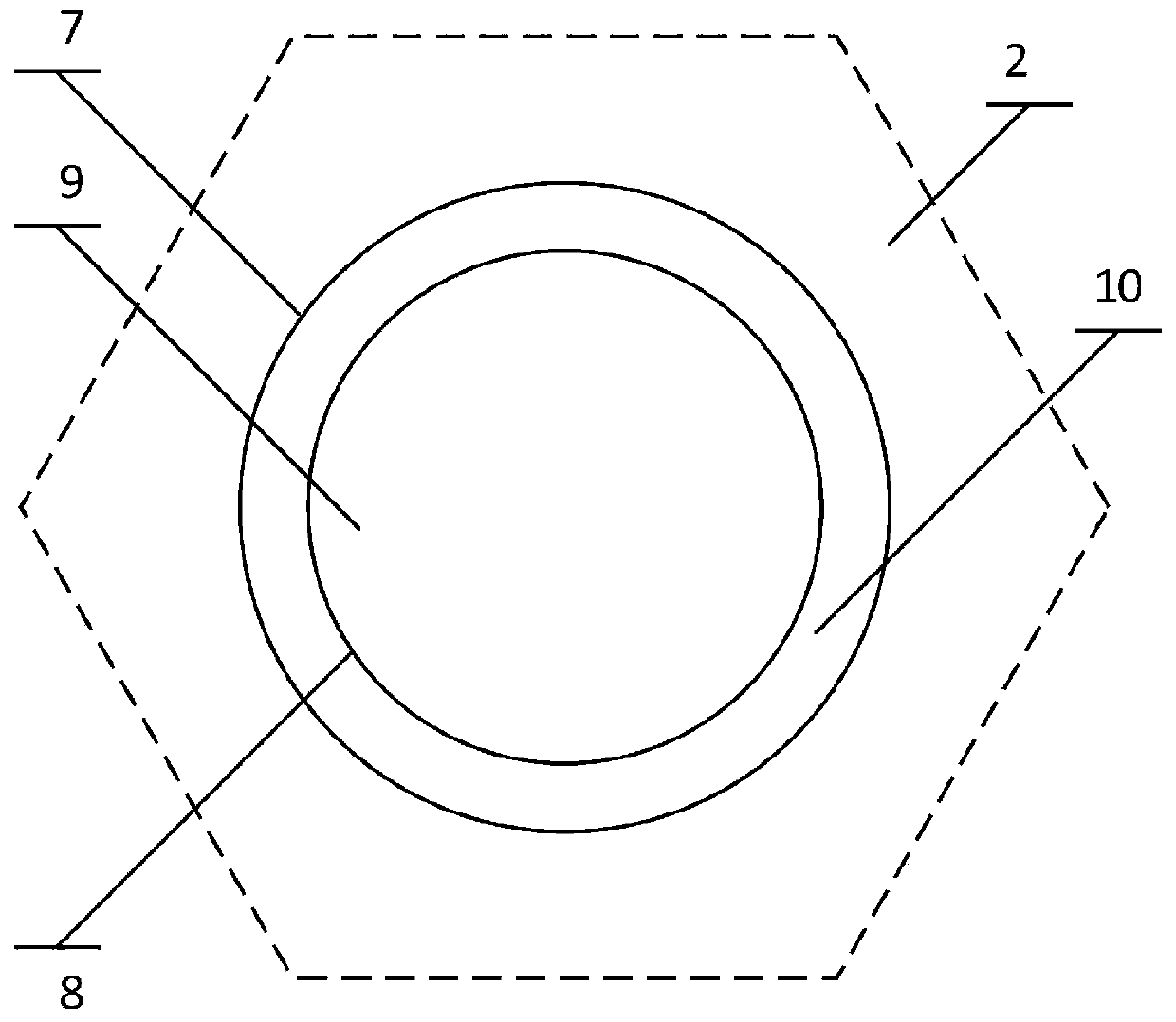

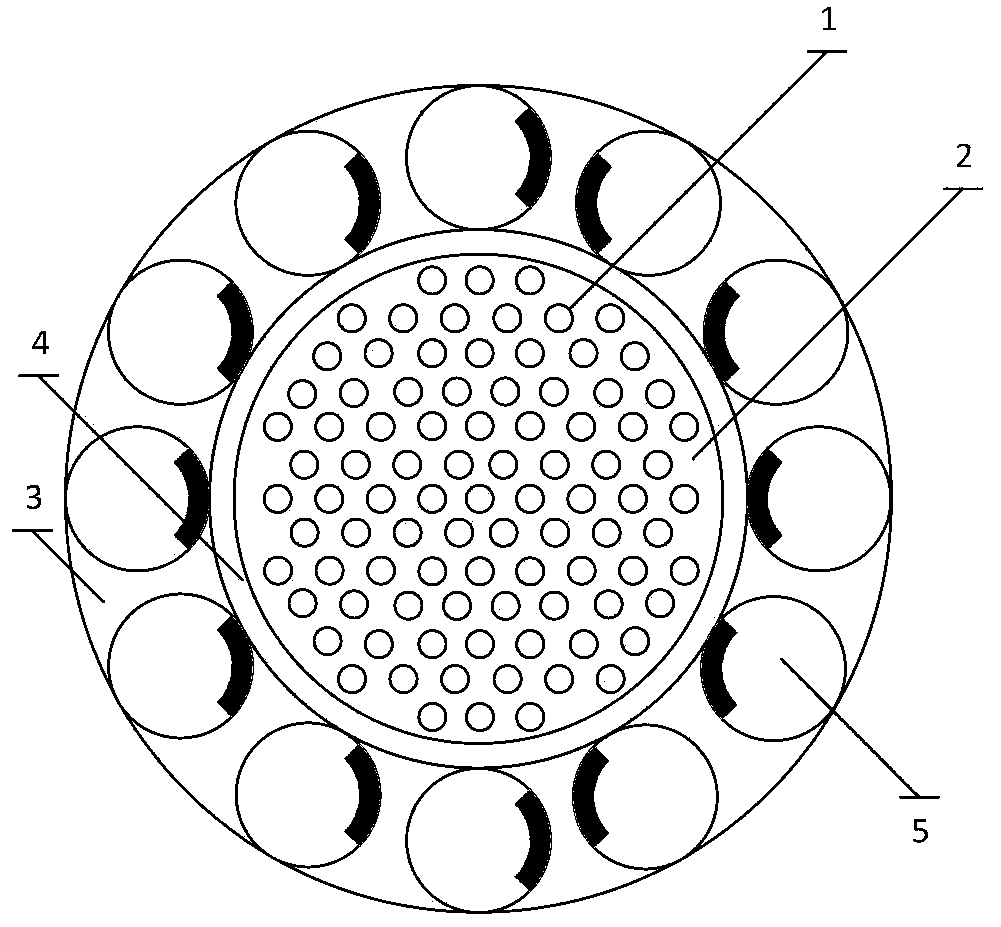

[0017] see Figure 1-4 Describe this embodiment, a liquid fuel heat pipe reactor, which includes a heat pipe 1, a fuel medium 2 and a reactor core 3, the fuel medium 2 is liquid fuel, the fuel medium 2 is located in the reactor core 3, and the heat pipe 1 is directly inserted into the fuel medium 2 in a hexagonal arrangement, and the upper part of the heat pipe 1 is located outside the fuel medium 2. The part of the heat pipe 1 inserted into the fuel medium 2 is a heating section, and the heat pipe 1 is located in the fuel medium 2 is the condensation section.

[0018] The fuel medium 2 described in this embodiment is a liquid molten salt material or a liquid metal material, which improves the heat and power distribution in the reactor. The heat pipe 1 has a double-wall structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com