Waxing and drying integrated machine

An all-in-one machine and drying box technology, applied in the field of all-in-one machines, can solve problems such as increasing production time, achieve the effects of improving production efficiency, saving production time, and improving waxing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

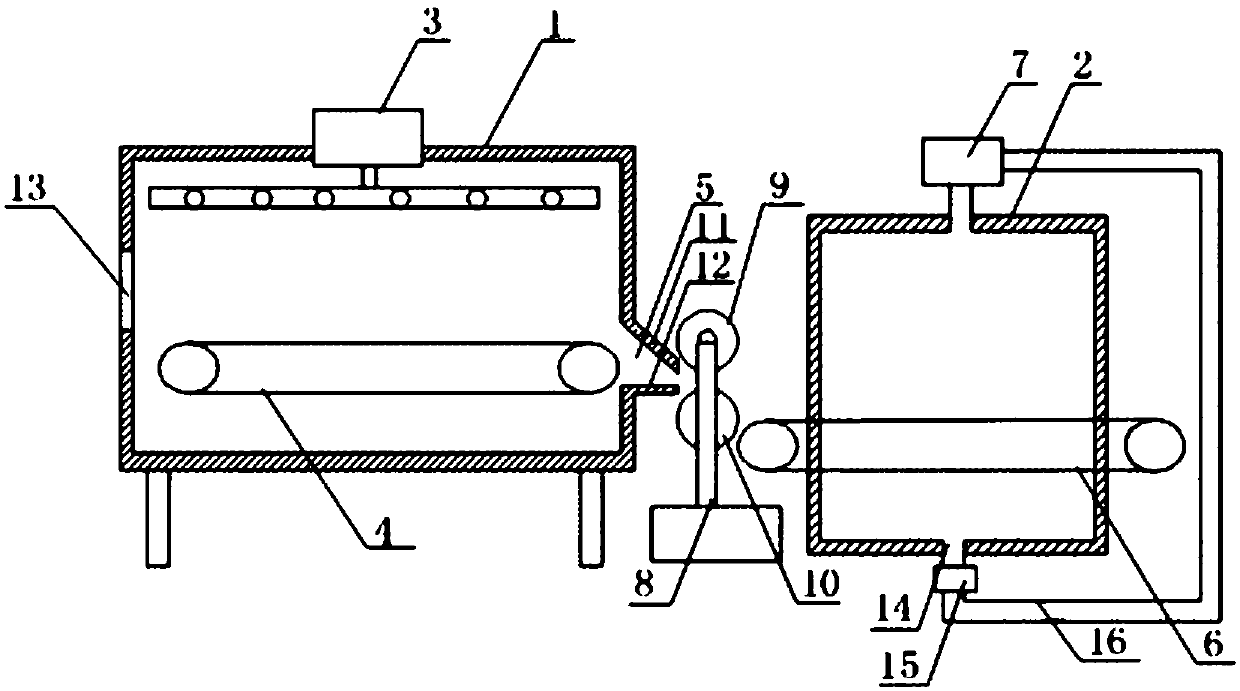

[0025] An all-in-one waxing and drying machine, comprising a closed chamber body 1 and a drying box 2, the closed chamber body 1 is provided with a wax mist generating device 3, and the mist outlet of the wax mist generating device 3 extends into the closed chamber body 1, A conveying device A4 is arranged in the closed chamber body 1, and a discharge port is opened on the side wall of the closed chamber body 1 opposite to the discharge end of the conveying device A4, and a diversion section 5 is connected to the discharge port; There is a conveying device B6, the feeding end of the conveying device B6 is arranged below the diversion section 5, and the upper end of the drying box 2 is connected with a hot air blower 7.

Embodiment 2

[0027] On the basis of Embodiment 1, this embodiment also includes polishing equipment arranged between the closed bin body 1 and the drying box 2. The polishing equipment includes a support 8 and a sponge roller A9 and a sponge roller B10 which are respectively rotatably arranged on the support 8. , the sponge roller A9 and the sponge roller B10 are set up and down relative to each other; a polishing passage is formed between the sponge roller A9 and the sponge roller B10, the end of the diversion section 5 faces the polishing passage, and the conveying device B10 is located below the polishing passage.

Embodiment 3

[0029] In this embodiment, on the basis of embodiment 1 or embodiment 2, the guide section 5 includes an upper baffle 11 and a lower baffle 12, the upper baffle 11 is arranged at the upper end of the discharge port, and the lower baffle 12 is arranged at At the lower end of the discharge port, the upper baffle plate 11 is inclined downward.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com