Line width adjustable laser cutting method and laser cutting device

A technology of laser cutting and laser beam, which is applied in the direction of laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of metal black spots residue and low cutting efficiency, so as to prevent the risk of short circuit, increase the width of laser cutting, avoid The effect of metal black spots remaining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

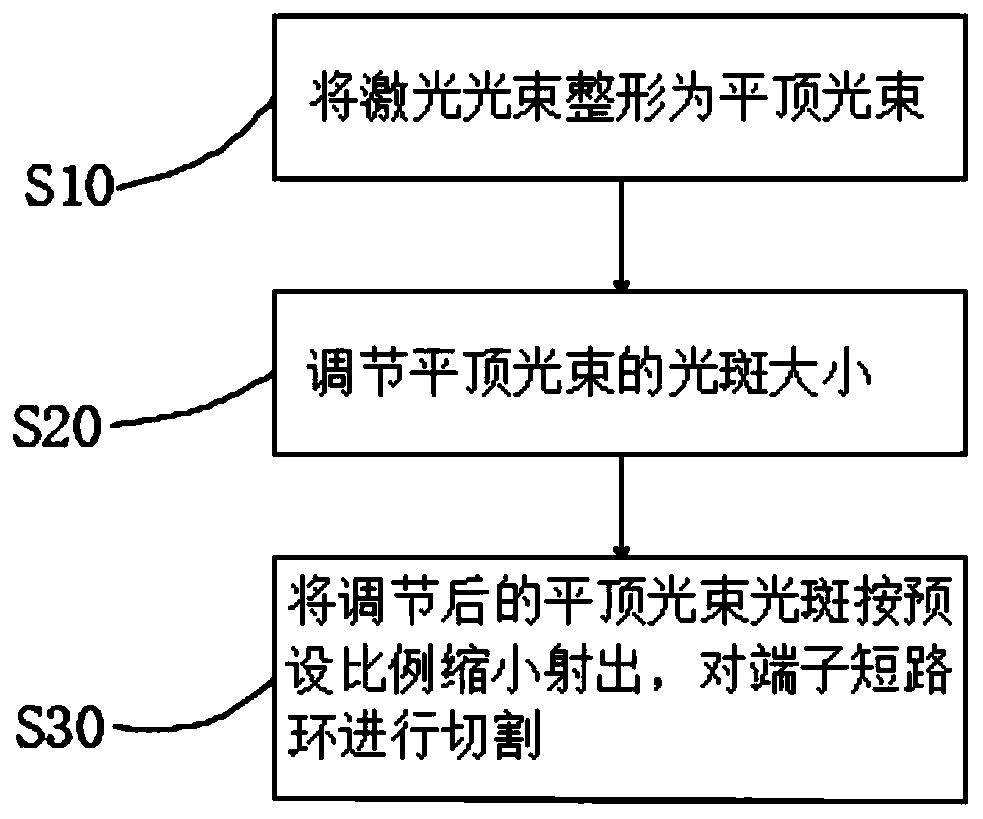

[0032] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

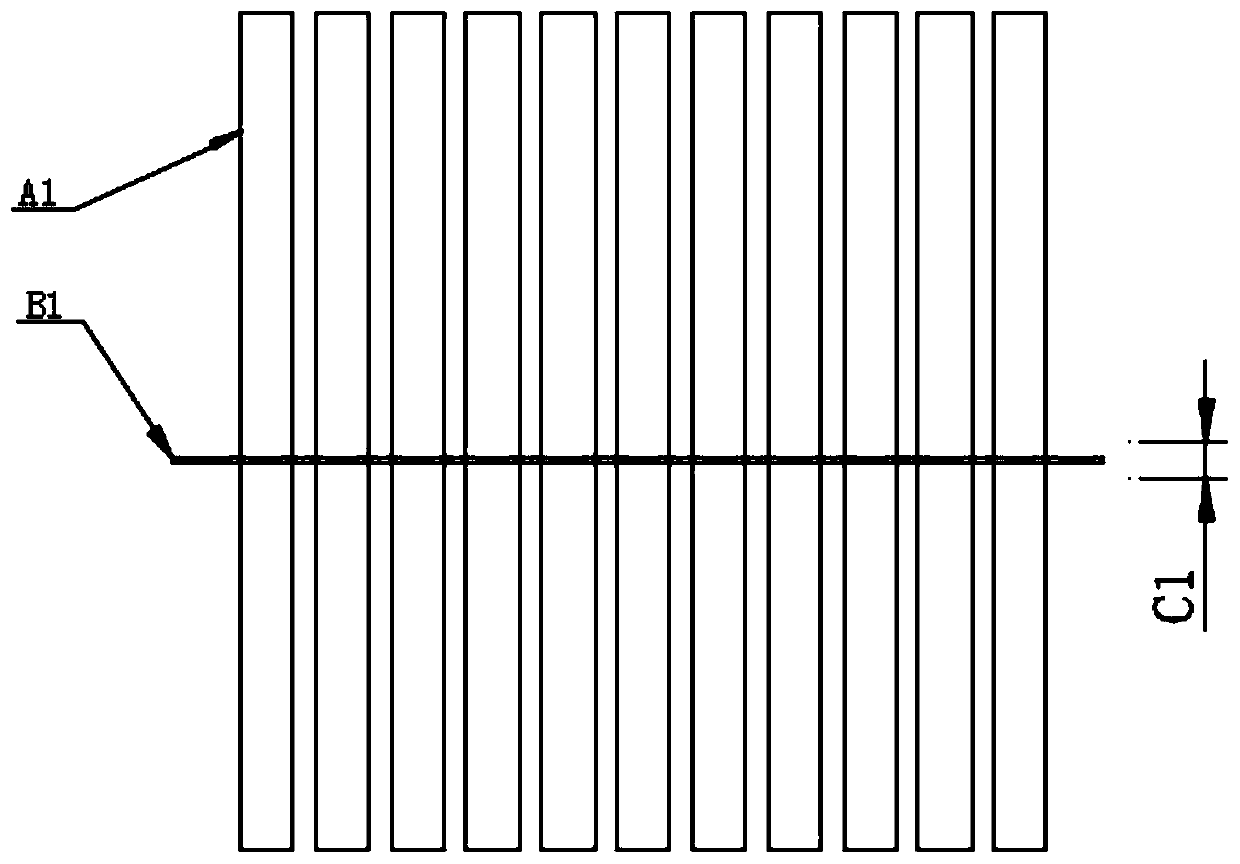

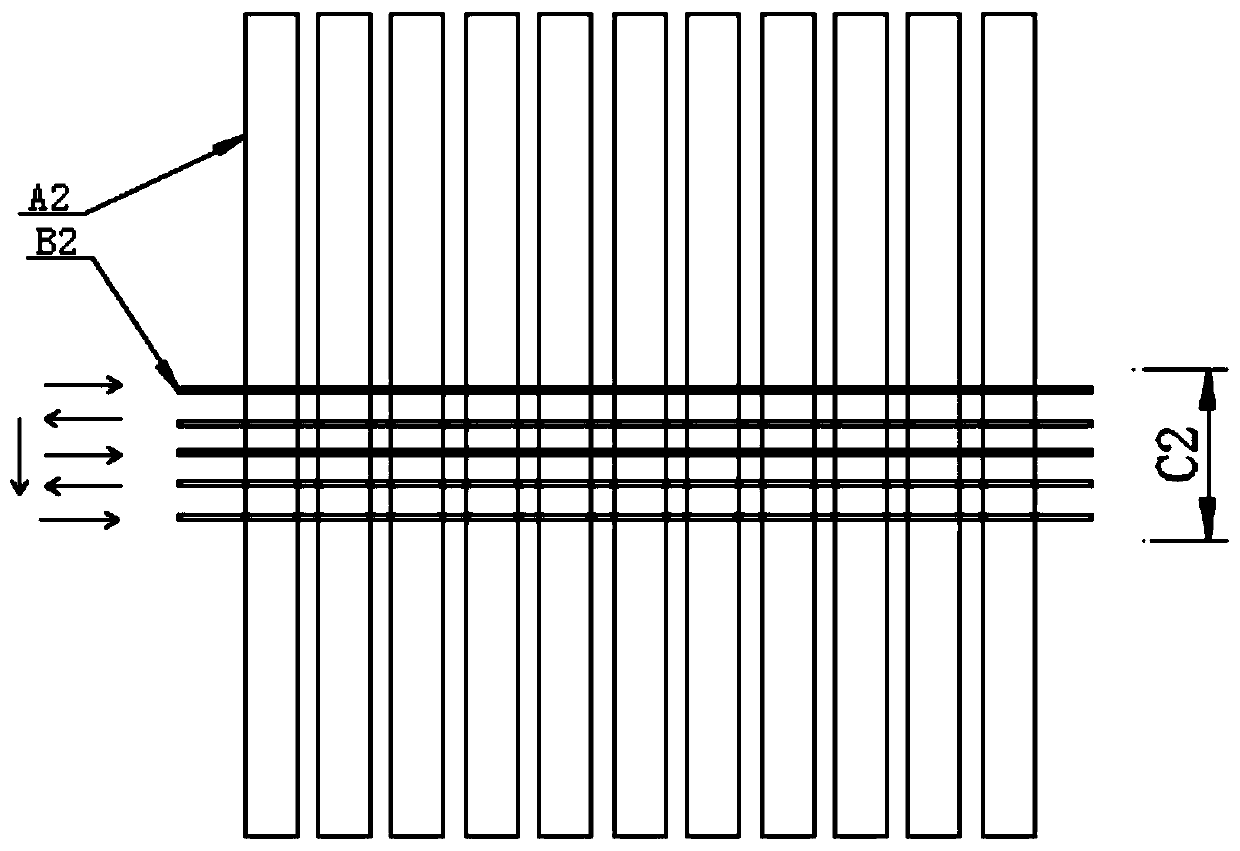

[0033] Such as image 3 As shown, the present invention provides a laser cutting method with adjustable line width, which is used to cut the short-circuit ring of the terminal of the liquid crystal panel. The method includes the following steps:

[0034] Step S10: performing beam shaping on the laser beam, and shaping the laser beam into a flat-hat beam. Wherein, the flat-hat beam is a flat-hat beam with uniform energy. Such as Figure 4 It is the energy density distribution diagram of the flat-hat beam. The flat-hat beam has a uniform energy distribution to ensure that the effect is consistent in the entire laser action area, and the middle and both sides of the cutting line can be removed cleanly, avoiding the edge of the cutting short-circuit ring. Metallic black dots remain to prevent the risk of short circuits.

[0035] Step S20: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com