Train

A technology for trains and train tubes, which is applied in the directions of railway car body parts, railway couplings, transportation and packaging, etc., which can solve the problems of large space occupied by the car end, difficult design of the length of the hose 1, and breakage, etc., to achieve space occupation big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

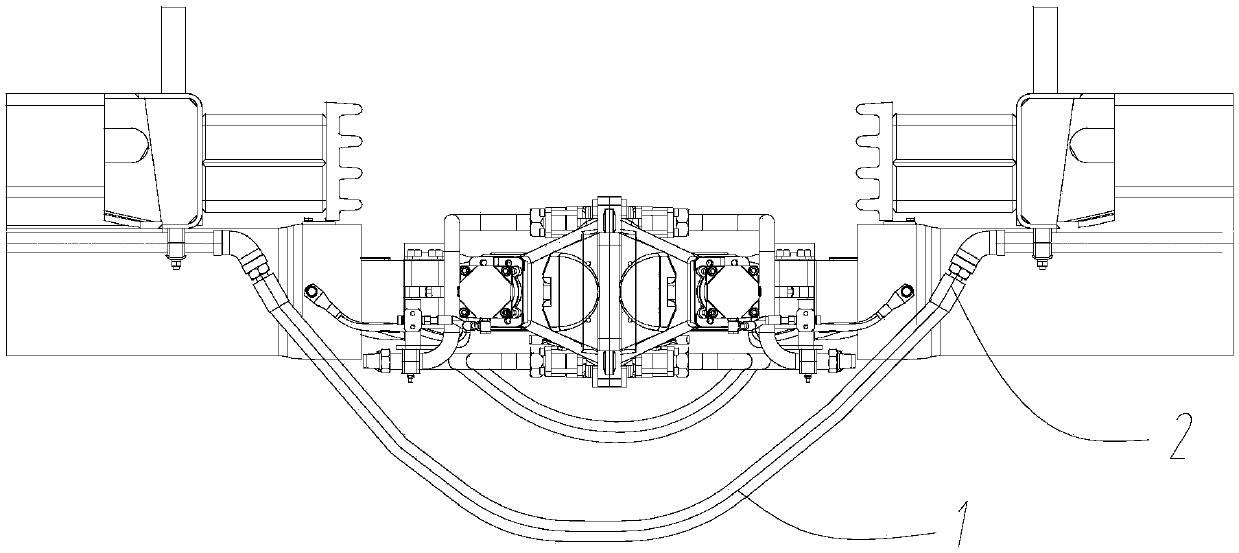

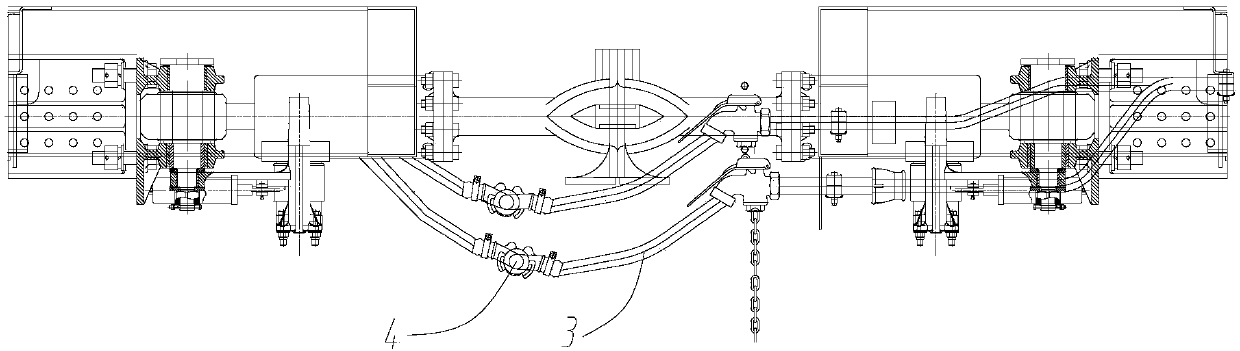

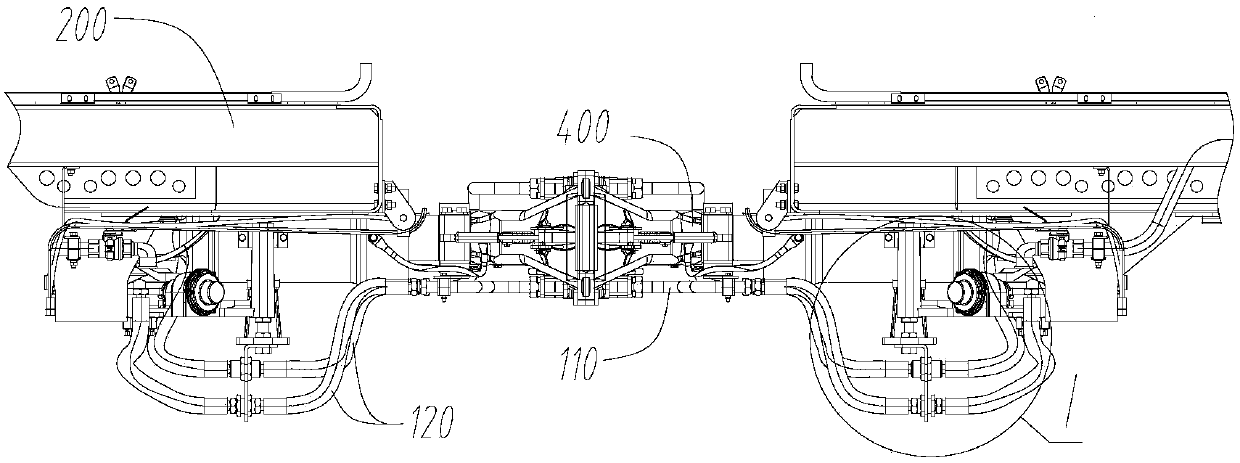

[0045] Figure 3 to Figure 6 As shown, the present invention relates to a train, the train includes an air brake system, and the air brake system includes an air supply brake pipeline 300 installed at the bottom of the train carriage 200, between adjacent carriages 200 The air supply brake pipeline 300 is connected through the vehicle-end connecting device 100, and the vehicle-end connecting device 100 includes:

[0046] The connecting pipe seat 110 is installed below the centering position of the coupler 400 of the adjacent carriage 200; the connecting pipe seat 110 is hollow inside, and its middle can be separated as the car coupler 400 is separated; The two ends of the connecting tube base 110 are provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com