A kind of calcium and magnesium sulfate double salt cementitious material and its preparation method and application

A technology of calcium magnesium sulfate physics and calcium magnesium sulfate chemistry, applied in the field of inorganic cementitious materials and building materials, can solve the problems of less distribution area, high processing cost, difficulty in recycling and harmless treatment, and achieve waste management and Efficient utilization, excellent physical and mechanical properties, and the effect of protecting social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 3

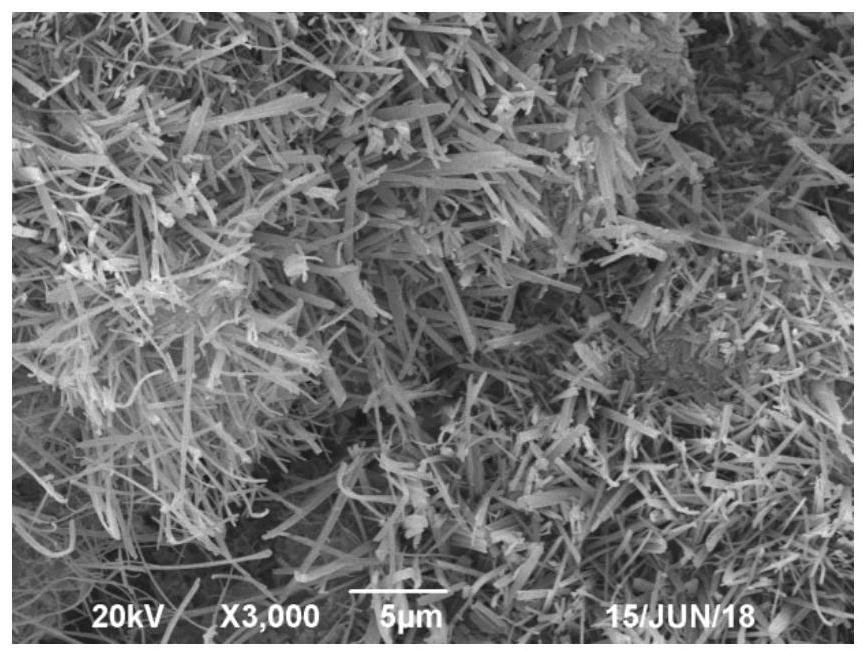

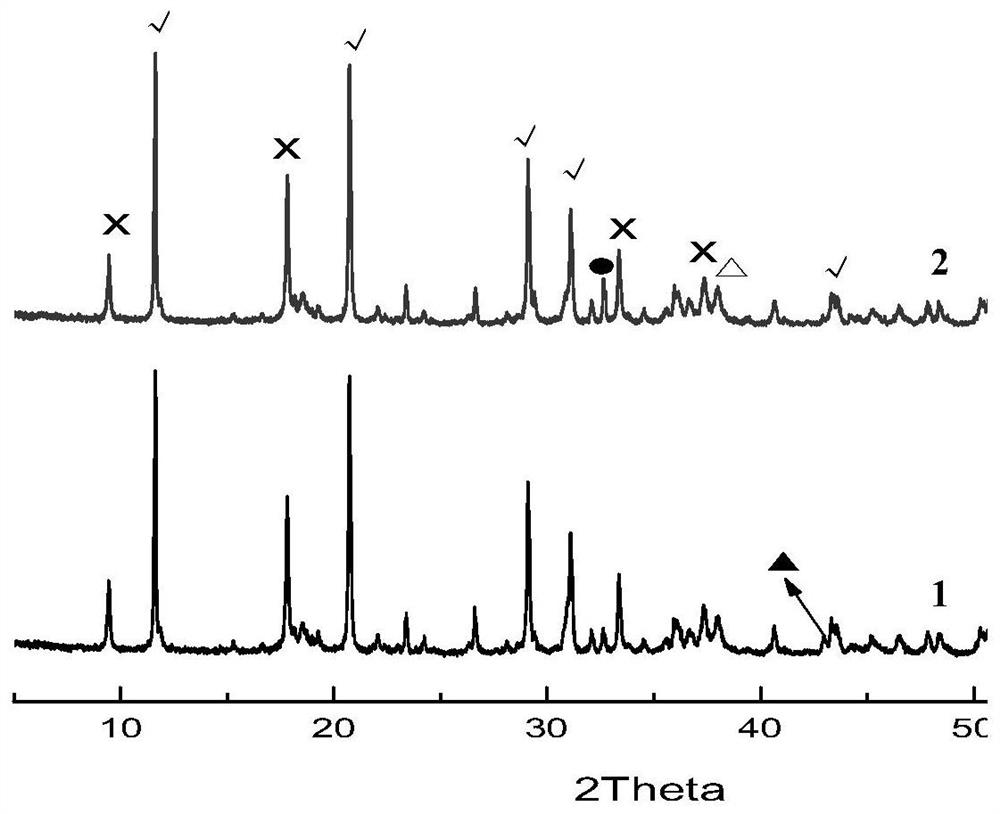

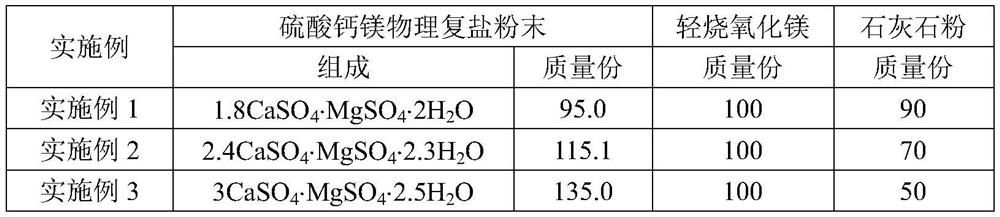

[0048] The calcium-magnesium sulfate double-salt cementing material powder in Examples 1 to 3 is formed by mixing calcium-magnesium sulfate physical double salt, light-burned magnesium oxide powder and limestone powder, and the design ratio of each component is shown in Table 2; wherein, Calcium-magnesium sulfate physical double salt is desulfurized dihydrate gypsum discharged from the calcium desulfurization process, and magnesium sulfate heptahydrate produced by the magnesium desulfurization process. After being heated and dehydrated in an open environment at 120-180 ° C, the solids are ground and dried. The powder obtained by passing through a 0.075 mm square hole sieve; light-burned magnesia was purchased from an enterprise in Haicheng City, Liaoning Province, and its chemical composition is shown in Table 3.

[0049]Composition and mix ratio of physical double salt cementing material in table 2 embodiment 1~embodiment 3

[0050]

[0051] Table 3 Chemical composition of...

Embodiment 4~ Embodiment 6

[0055] The calcium-magnesium sulfate double-salt cementing material powder in embodiment 4~embodiment 6 is mixed by calcium-magnesium sulfate physical double salt and light-calcined magnesium oxide powder, and its each component design ratio is shown in Table 4; Wherein, calcium-magnesium sulfate The physical double salt is phosphogypsum slag discharged from a phosphorus chemical enterprise, and magnesium sulfate heptahydrate produced by the magnesium desulfurization process. After being heated and dehydrated in an open environment at 120-180°C, the solid is ground and passed through a 0.075mm Square-hole sieve, the powder that makes; Lightly burned magnesia is identical with embodiment 1.

[0056] In order to test the strength of the calcium-magnesium sulfate double-salt cementing material in Examples 4 to 6, these three powders were mixed with water to form a double-salt cementing material slurry with water-solid ratios of 0.55, 0.41 and 0.39, respectively. After mixing even...

Embodiment 7~ Embodiment 9

[0062] The calcium-magnesium sulfate double-salt cementing material powder in embodiment 7~embodiment 9 is made of calcium-magnesium sulfate chemical double salt [Mg 2 Ca(SO 4 ) 3 ], light-burned magnesia powder and desulfurized building gypsum are mixed, and the design ratio of each component is shown in Table 6; wherein, calcium magnesium sulfate chemical double salt is desulfurized dihydrate gypsum discharged from the calcium desulfurization process, magnesium desulfurization After the magnesium sulfate heptahydrate produced by the process is fired in a high-temperature furnace at 725°C to 750°C, the cooled solid is ground and passed through a 0.075mm square hole sieve to obtain a powder; desulfurized building gypsum and comparative example 1 Identical; Lightly burned magnesia powder is identical with embodiment 1.

[0063] Composition and compounding ratio (mass parts) of chemical double salt cementing material in Table 6 embodiment 7~9

[0064] Example Calc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com