Biological active ceramic bracket with nano/micron hierarchical pore structure and preparation method of biological active ceramic bracket

A bioactive ceramic, multi-level pore technology, applied in ceramic products, other household appliances, applications, etc., can solve the problems of difficult to precisely control the size and distribution of nano-pores, poor repeatability of the hierarchical pore structure, etc., to increase the overall Porosity, good application value, overcoming the effect of high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

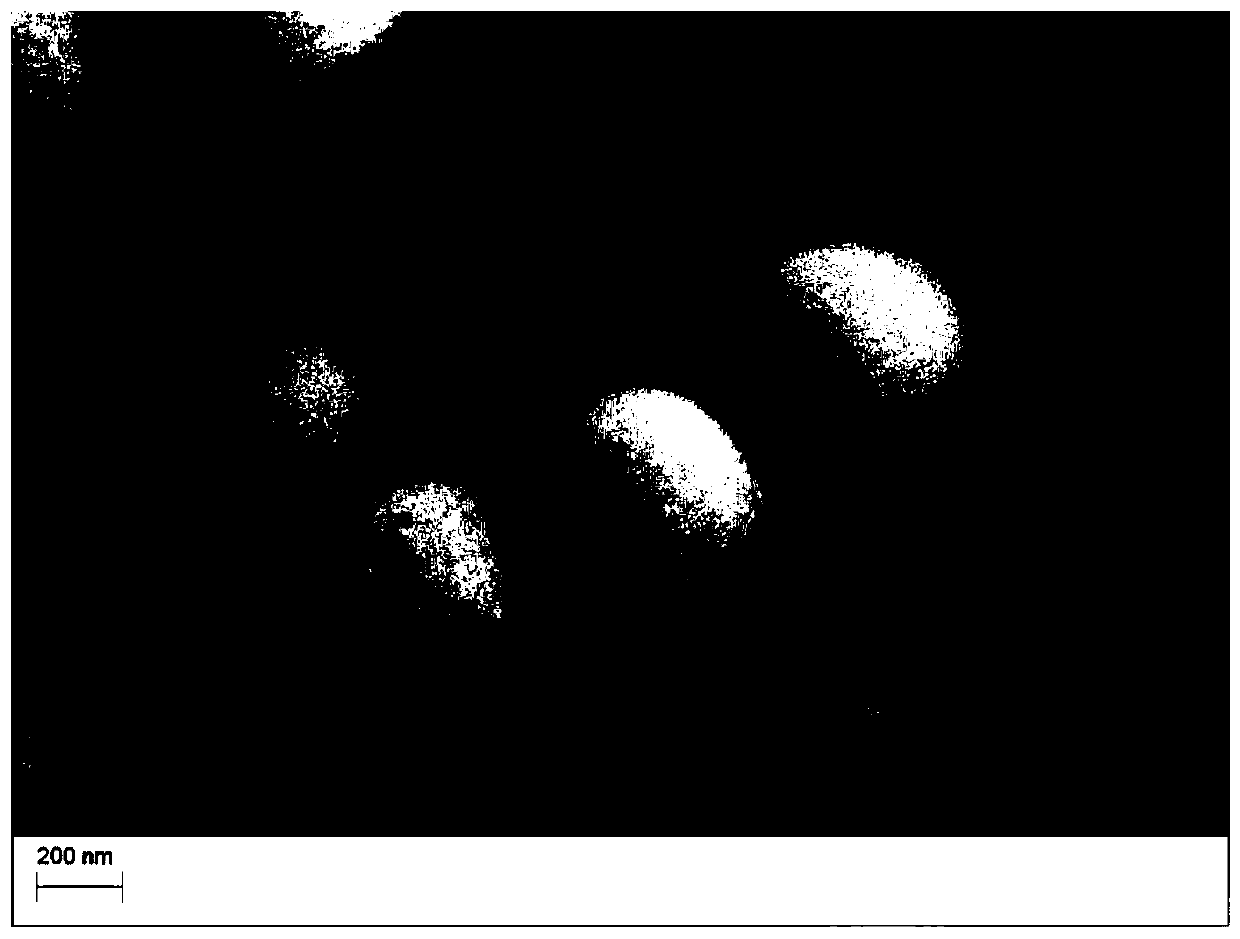

[0037] (1) Preparation of monodisperse PS microspheres: first mix 0.4g K 2 S 2 o 8 Dissolve in 20g of deionized water, then stir and mix 0.12g of NaCl, 172g of deionized water and 8g of styrene, under a nitrogen atmosphere, heat the oil bath to 75°C, add K dropwise 2 S 2 o 8 The solution was dripped within 30 minutes, kept warm for 4 hours, and a white suspension was obtained; then centrifuged at 10,000 rpm / min for 10 minutes in a high-speed centrifuge, washed with deionized water and centrifuged again for three times, and finally washed with absolute ethanol and centrifuged Three times, vacuum dry at 40°C for 24h, as figure 1 As shown, a PS microsphere powder with a particle size of 600 nm was obtained.

[0038] (2) Preparation of bioactive ceramic slurry containing PS microspheres: 0.2756g hydroxypropyl methylcellulose (HPMC) was dissolved in 9ml of ammonium polyacrylate solution, and the pH value of the solution was adjusted to 9 with 1M ammonia water Add 22.9745g of ...

Embodiment 2

[0041] (1) Preparation of monodisperse PS microspheres: first mix 0.4g K 2 S 2 o 8 Dissolve in 20g of deionized water, then stir and mix 0.12g of NaCl, 172g of deionized water and 8g of styrene, under a nitrogen atmosphere, heat the oil bath to 75°C, add K dropwise 2 S 2 o 8 The solution was dripped within 30 minutes, kept warm for 4 hours, and a white suspension was obtained; then centrifuged at 10,000 rpm / min for 10 minutes in a high-speed centrifuge, washed with deionized water and centrifuged again for three times, and finally washed with absolute ethanol and centrifuged Three times, vacuum drying at 40°C for 24 hours to obtain PS microsphere powder with a particle size of 600nm

[0042] (2) Preparation of bioactive ceramic slurry containing PS microspheres: 0.2756g hydroxypropyl methylcellulose (HPMC) was dissolved in 9ml of ammonium polyacrylate solution, and the pH value of the solution was adjusted to 9 with 1M ammonia water Add 22.9745g of β-TCP powder and grind ...

Embodiment 3

[0045] (1) Preparation of monodisperse PS microspheres: first mix 0.4g K 2 S 2 o 8 Dissolve in 20g of deionized water, then stir and mix 0.12g of NaCl, 172g of deionized water and 8g of styrene, under a nitrogen atmosphere, heat the oil bath to 75°C, add K dropwise 2 S 2 o 8 The solution was dripped within 30 minutes, kept warm for 4 hours, and a white suspension was obtained; then centrifuged at 10,000 rpm / min for 10 minutes in a high-speed centrifuge, washed with deionized water and centrifuged again for three times, and finally washed with absolute ethanol and centrifuged Three times, vacuum drying at 40°C for 24 hours to obtain PS microsphere powder with a particle size of 600nm

[0046] (2) Preparation of bioactive ceramic slurry containing PS microspheres: 0.2756g hydroxypropyl methylcellulose (HPMC) was dissolved in 9ml of ammonium polyacrylate solution, and the pH value of the solution was adjusted to 9 with 1M ammonia water Add 22.9745g of β-TCP powder and grind ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com