Deep foundation pit continuous retaining wall and construction method thereof

A construction method and technology for deep foundation pits, which are applied in infrastructure engineering, excavation, artificial islands, etc., can solve the problems of increasing the thickness of the continuous retaining wall, the inward pressure of the foundation pit wall, and increasing the construction cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

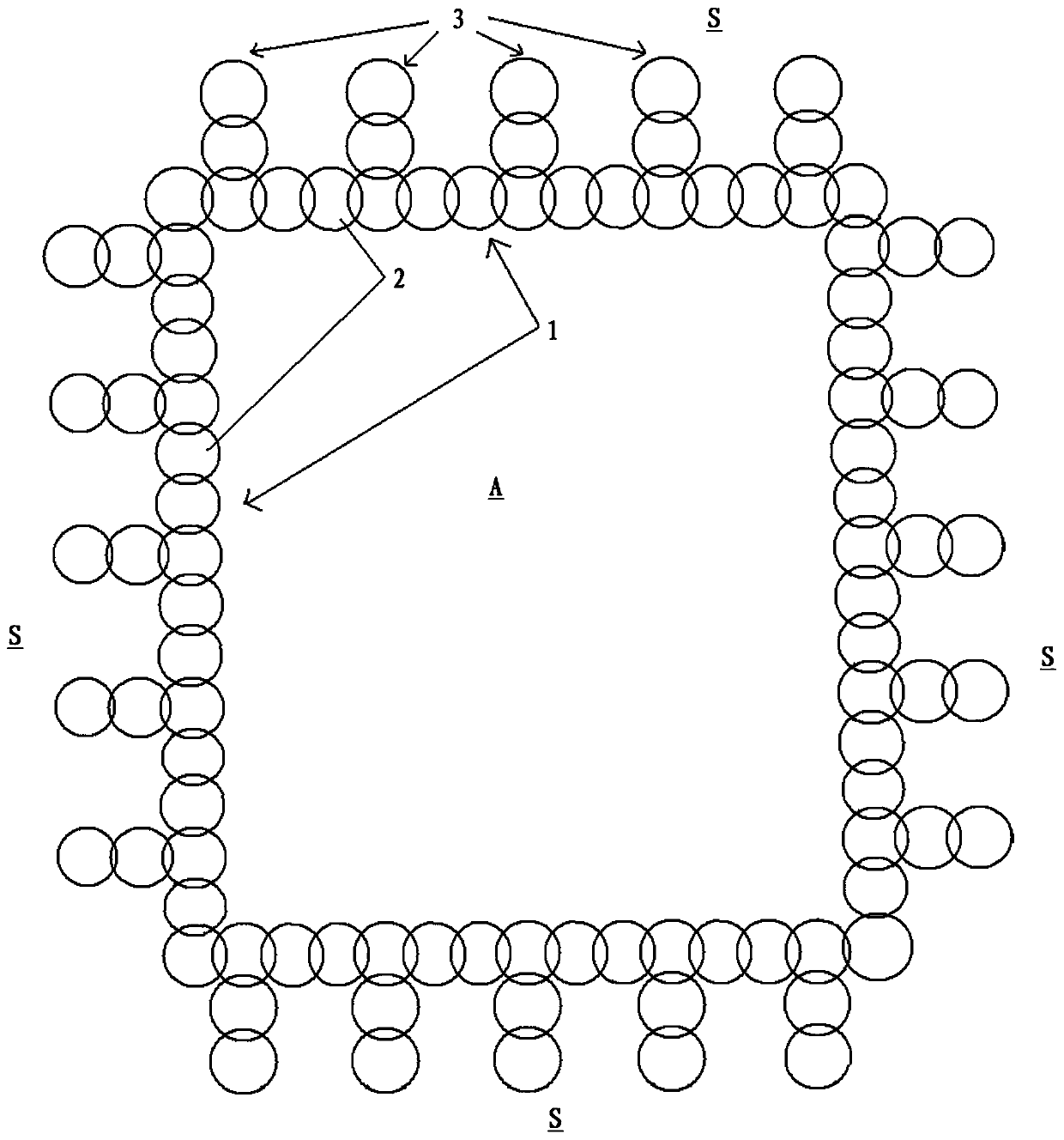

[0033] Such as figure 1 The shown continuous retaining wall of a deep foundation pit includes: a continuous occlusal portion 1, which is composed of at least one layer of cement-soil piles 2 that are continuously occluded with each other; and is annularly arranged around the foundation pit A; it also includes: several protrusions 3, The foundation pit A extends laterally toward the soil body S, and each of the protruding parts is composed of at least two cement-soil piles 2 that interlock with each other, wherein the protruding parts 3 and the continuous occlusal part 1 2 joints of cement-soil pile bodies arranged at intervals.

Embodiment 2

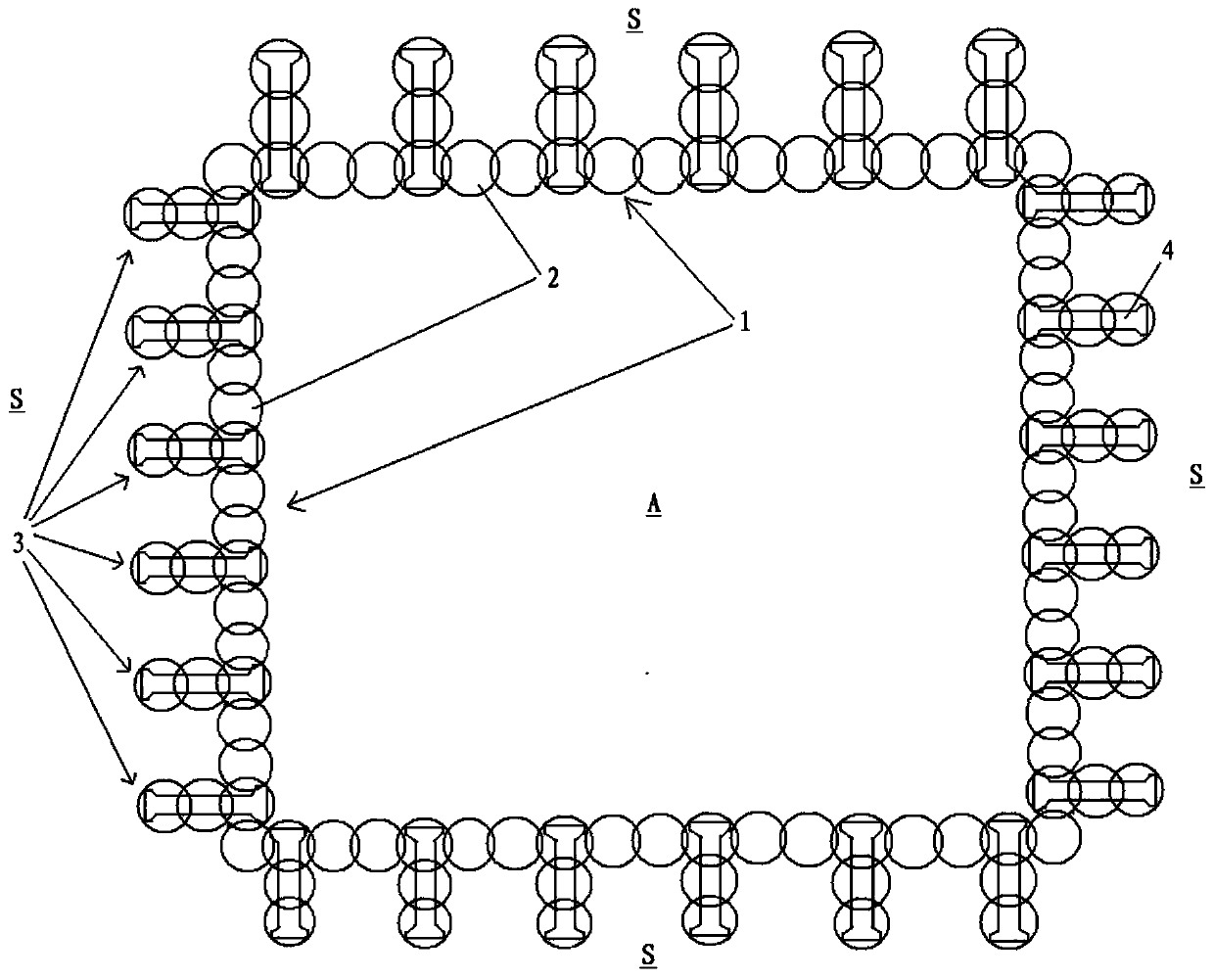

[0035] Such as figure 2 The continuous retaining wall of the deep foundation pit shown, wherein, the difference between this embodiment and embodiment 1 is that each cement-soil pile body 2 in the protrusion 3 and the continuous retaining wall engaged with the protrusion 3 At least one prefabricated sheet pile 4 or at least one section steel (not shown) is longitudinally inserted in the cement-soil pile body 2 in the joint portion 1 . The prefabricated sheet pile is an I-type sheet pile (such as figure 2 As shown), it can also be T-shaped sheet pile or I-shaped sheet pile; when the inserted section steel is I-shaped steel, it can also be T-shaped steel or I-shaped steel. For not yet out.

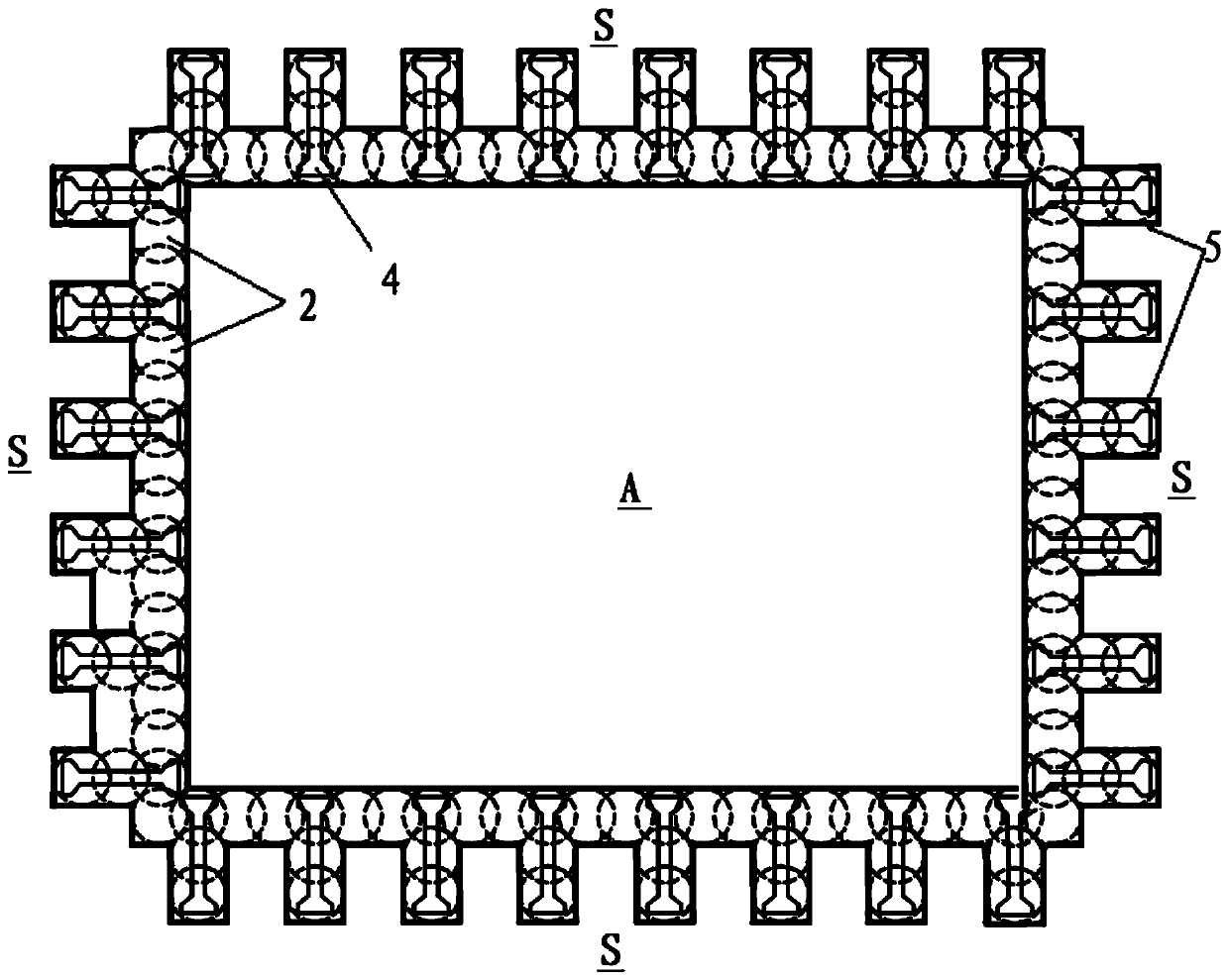

[0036] As a preferred embodiment, such as image 3 As shown, the continuous retaining wall of the deep foundation pit may also include: a rigid connection structure 5, which is arranged on the top of the prefabricated sheet pile 4, so as to form an integral rigid connection with the pre...

Embodiment 3

[0039] An embodiment of the present invention provides a construction method for a continuous retaining wall of a deep foundation pit, wherein, the continuous retaining wall of a deep foundation pit includes: a continuous occlusal portion, which is formed by at least one layer of cement-soil pile bodies continuously occluded; and an annular Arranged around the foundation pit; the continuous retaining wall of the deep foundation pit also includes: several protrusions, which are arranged laterally from the foundation pit to the soil, and each of the protrusions is composed of at least two cement-soil piles interlocking with each other body structure, wherein, the protruding portion engages with the cement-soil piles arranged at intervals in the continuous occlusal portion; such as Figure 4 As shown, the construction method includes the following steps: a. drilling pile holes, wherein the pile holes include at least one pile hole of the cement-soil pile body of the protrusion, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com