Double-sided heating steam generator with spiral tooth-shaped structures

A steam generator and double-sided heating technology, applied in steam generation, steam generation methods, steam boilers, etc., can solve the problems of poor water dispersion, high cost, affecting heating efficiency and heat utilization efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

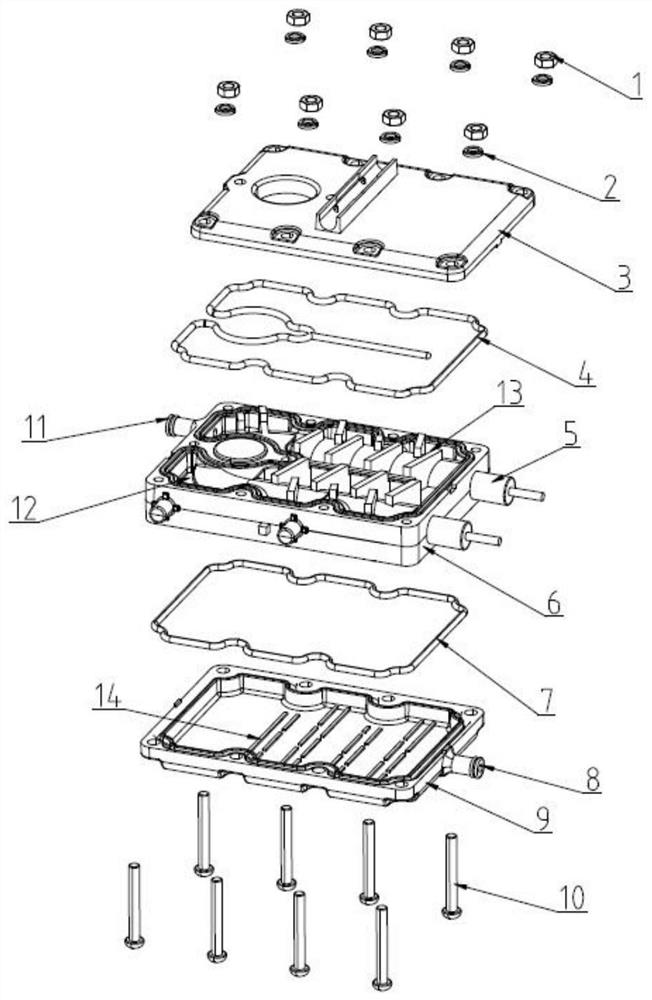

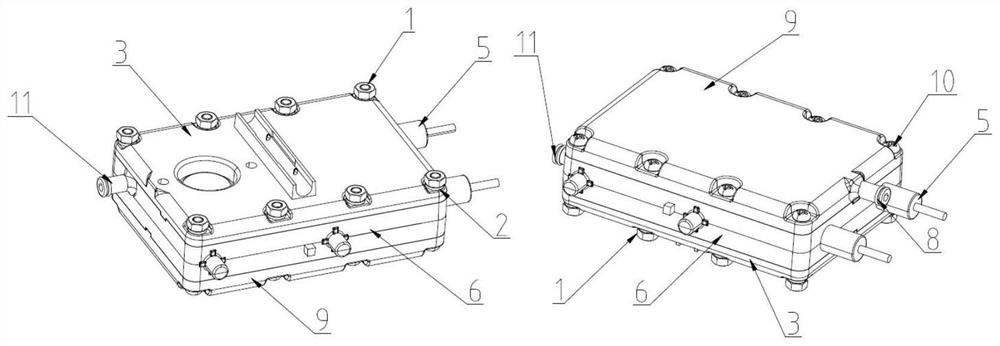

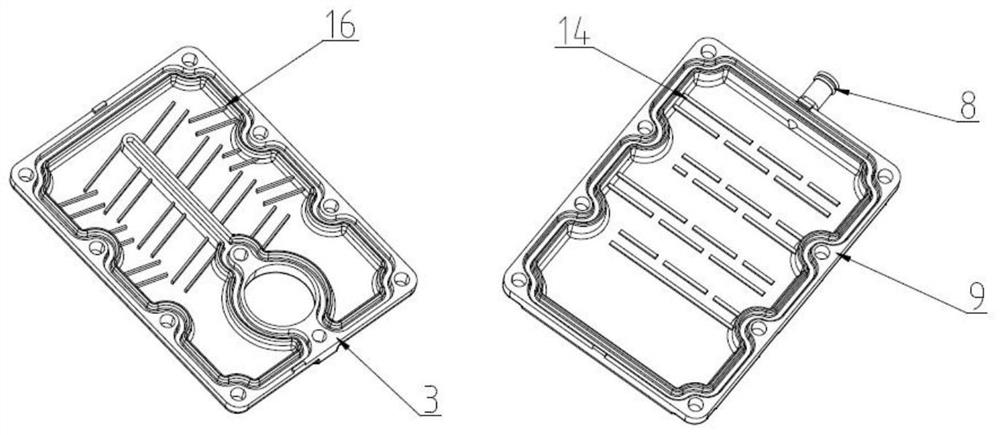

[0026] Such as Figure 1-5 As shown, a double-sided heating steam generator with a spiral tooth structure includes a heating element 6, and a heating tube 5 is die-cast in the heating element 6, such as image 3 As shown, the upper and lower ends of the heating element 6 are fastened with an upper cover 3 and a lower cover 9 respectively, forming airtight cavities at the upper and lower ends of the heating element 6 respectively. The heating element 6 and the upper and lower covers 9 are assembled and fixed by locking screws 10, nuts 1 and spring washers 2. Silicone sealing rings 4, 7 for sealing are also provided between the heating element 6 and the upper and lower covers 3, 9.

[0027] The upper end surface of the heating element 6 is provided with a plurality of helical tooth-shaped structures 13 along the axial direction of the heating tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com