Micro full-medium self-supporting optical cable

A self-supporting optical cable and all-dielectric technology, applied in the direction of light guides, optics, optical components, etc., can solve the problems of structural strength and unsatisfactory volume, and achieve the effects of improving overall performance, reducing outer diameter, and increasing tensile value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

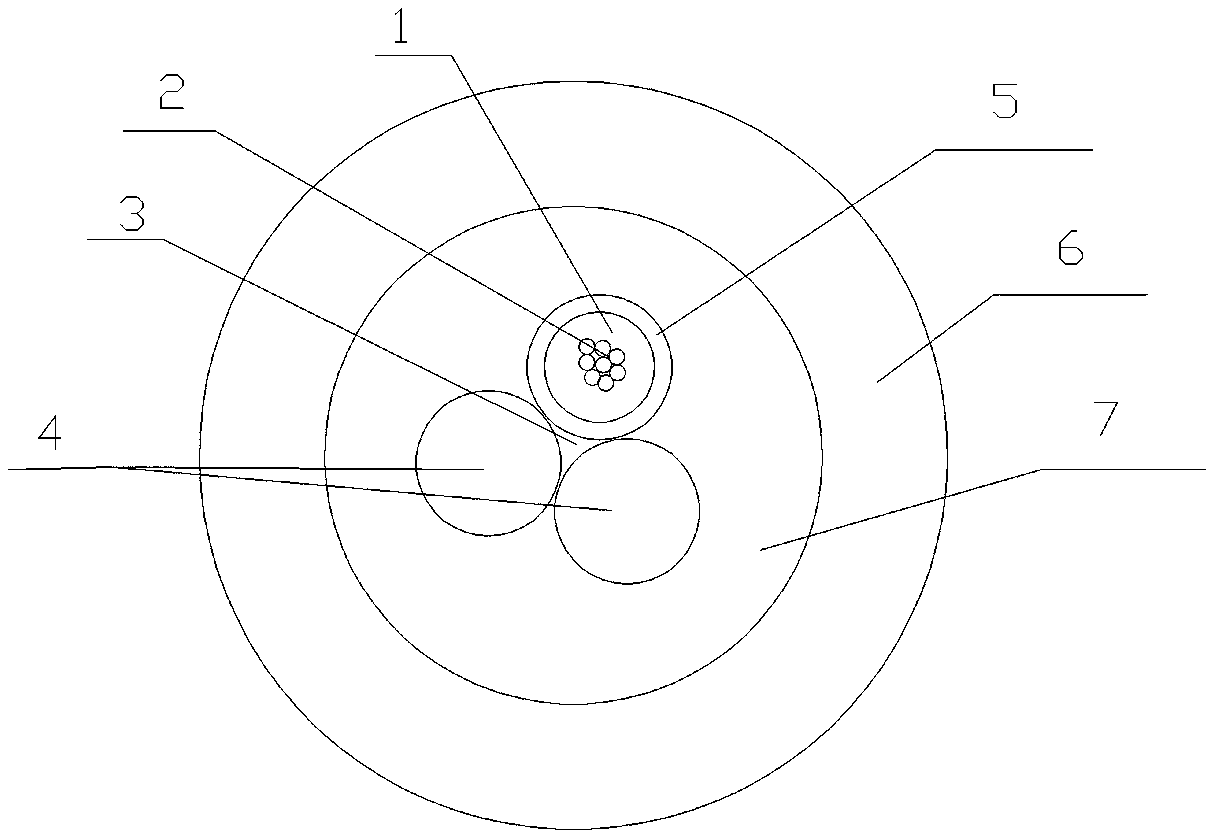

[0013] Such as figure 1 As shown, a miniature all-dielectric self-supporting optical fiber cable includes a sheath 6, an optical fiber cable core 2 and a strength member 4 are arranged in the sheath, and a loose tube 5 is provided on the outer jacket of the optical fiber cable core. In the casing 5, two reinforcements 4 are provided, which are respectively located on both sides of the loose casing and twisted with the loose casing. 12 groups of fiber optic cable cores are arranged in the loose tube 5, and a fiber paste 1 is arranged between the fiber optic cable core and the loose tube. A water blocking yarn 3 is arranged at the intermediate position formed by the reinforcing member and the loose tube. A water-blocking aramid yarn 7 is arranged between the reinforcement, the loose tube and the sheath. The reinforcement is an FRP reinforcement, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com