A construction method of an automatic plug-in vibrating device for the second lining concrete of a tunnel

An automatic insertion and vibrating device technology, which is applied in the direction of tunnel lining, tunnel, earthwork drilling and mining, etc., can solve the problems that concrete cannot be vibrated manually, concrete is not dense, and the second lining of the vault is empty, so as to reduce the labor intensity of operation and safety risks, improve construction efficiency and quality, and realize the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

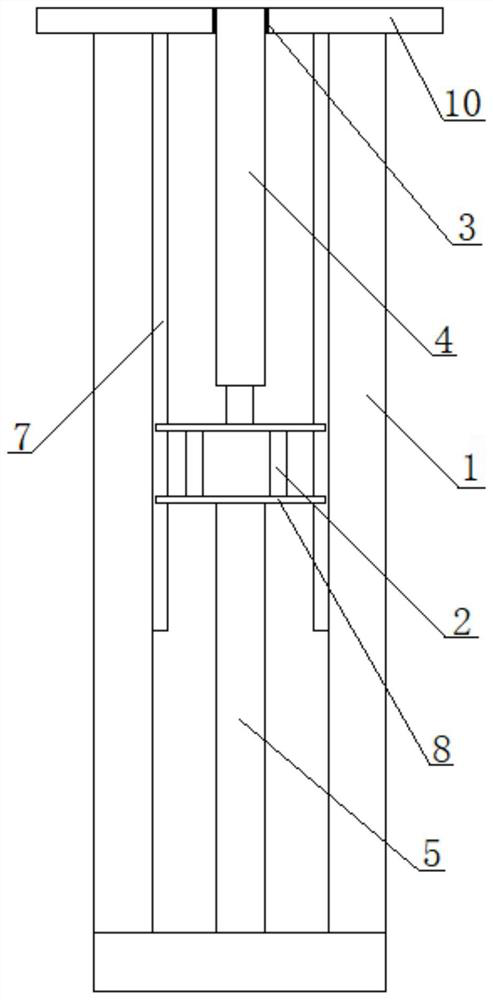

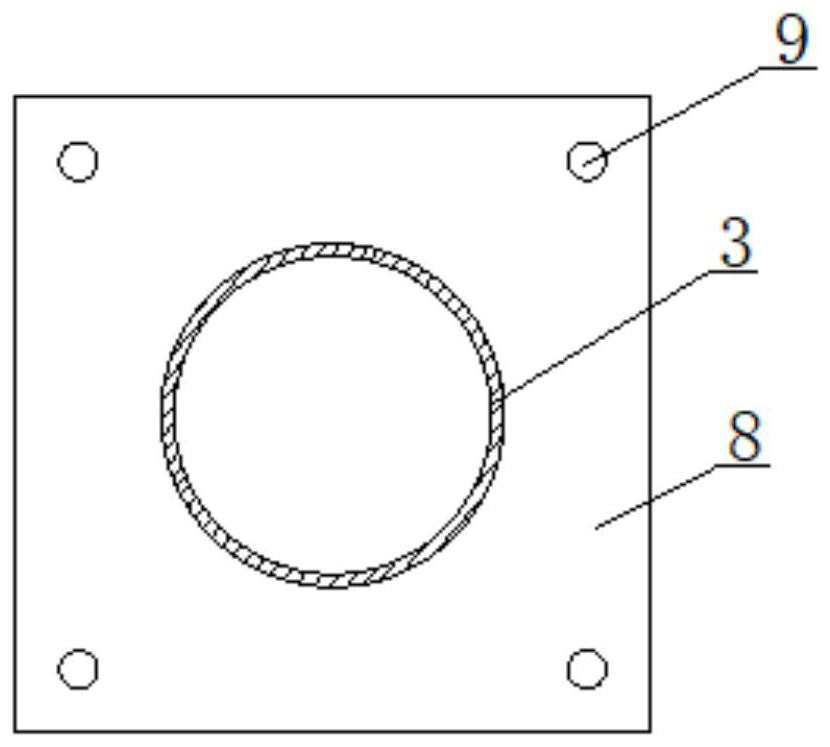

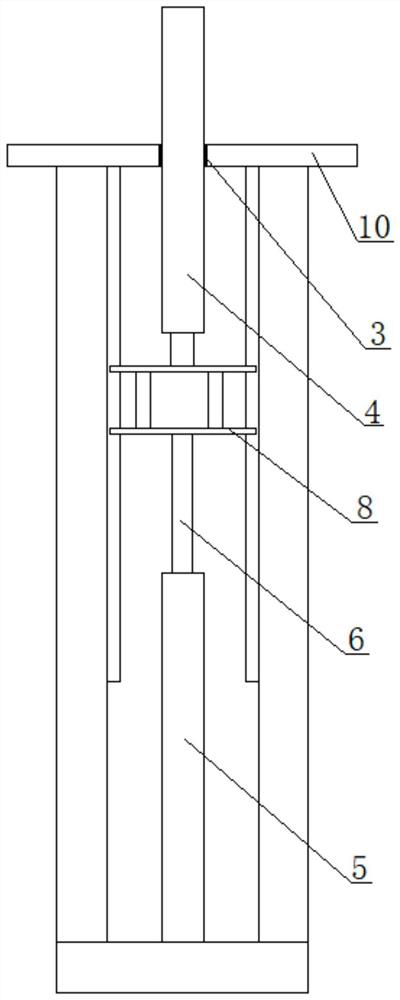

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] see Figure 1 to Figure 3 , a construction method of an automatic plug-in vibrating device for the second lining of a tunnel, relating to the automatic vibration of concrete in the tunnel lining construction process; wherein the automatic plug-in vibrating device includes a steel frame 1, a pneumatic jack 5, a jacking Slideway 7, high-frequency vibrating rod 4, gas compressor and electric control box.

[0034] see Figure 1 to Figure 3 , the steel frame 1 is installed on the back side of the steel formwork 10 of the second lining trolley of the tunnel, that is, the steel frame 1 is installed on the surface of the steel formwork 10 of the second lining trolley of the tunnel facing the inside of the trolley, and the steel frame 1 is installed Closely attached to the back of the steel formwork 10 of the second lining trolley. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com