Blade clearance monitoring method for wind generating set

A technology for wind turbines and blades, which is applied in the monitoring of wind turbines, wind turbines, and engines, can solve the problems of inconvenient installation and maintenance, high price, and large amount of data, so as to reduce the difficulty of installation and maintenance and save costs. , the effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific examples.

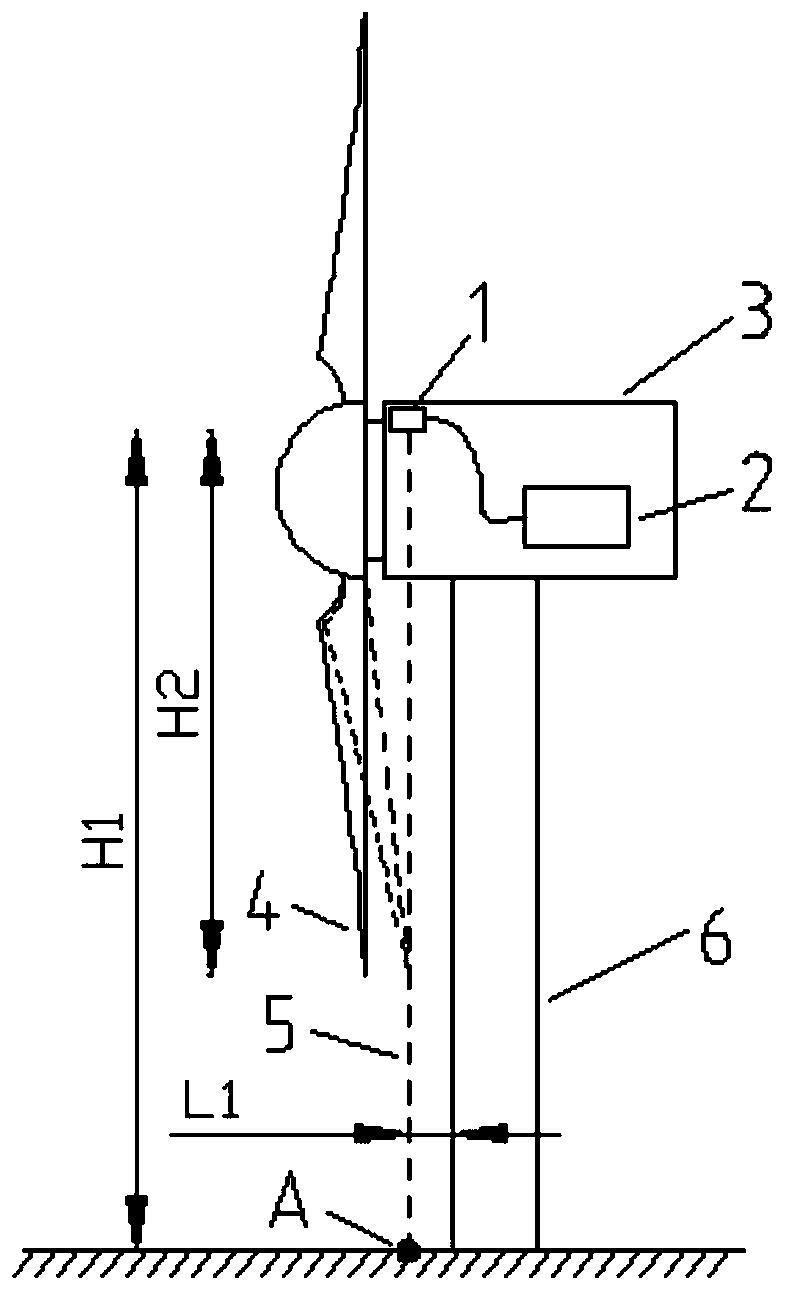

[0014] Such as figure 1 As shown, the nacelle 3 of the wind generator set is installed on the top of the tower 6, the control system 2 of the wind generator set is installed in the nacelle 3, and the wind wheel composed of three blades 4 rotates clockwise after absorbing wind energy.

[0015] The specific conditions of the blade clearance monitoring method of the wind power generating set provided in this embodiment are as follows:

[0016] First, determine the safe clearance distance L1 between the blade 4 and the outer wall of the tower 6 according to theoretical calculations, then set a point A at the distance L1 from the ground to the outer wall of the tower 6, and then install a laser rangefinder 1 with a visible light reference on the side of the nacelle 3 , the laser 5 emitted by the laser rangefinder 1 is vertically downward, and when the visible light hits the fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com