Sintering ore vertical cooling kiln with uniform ventilation device

A technology for cooling kilns and sintered ore, which is applied in the direction of processing discharged materials, waste heat treatment, furnaces, etc., and can solve problems such as difficulty in adjusting air resistance, unstable and uneven distribution of heat exchange chambers, and inability to change air resistance in real time, achieving structural Scientific and reasonable, uniform and high ventilation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

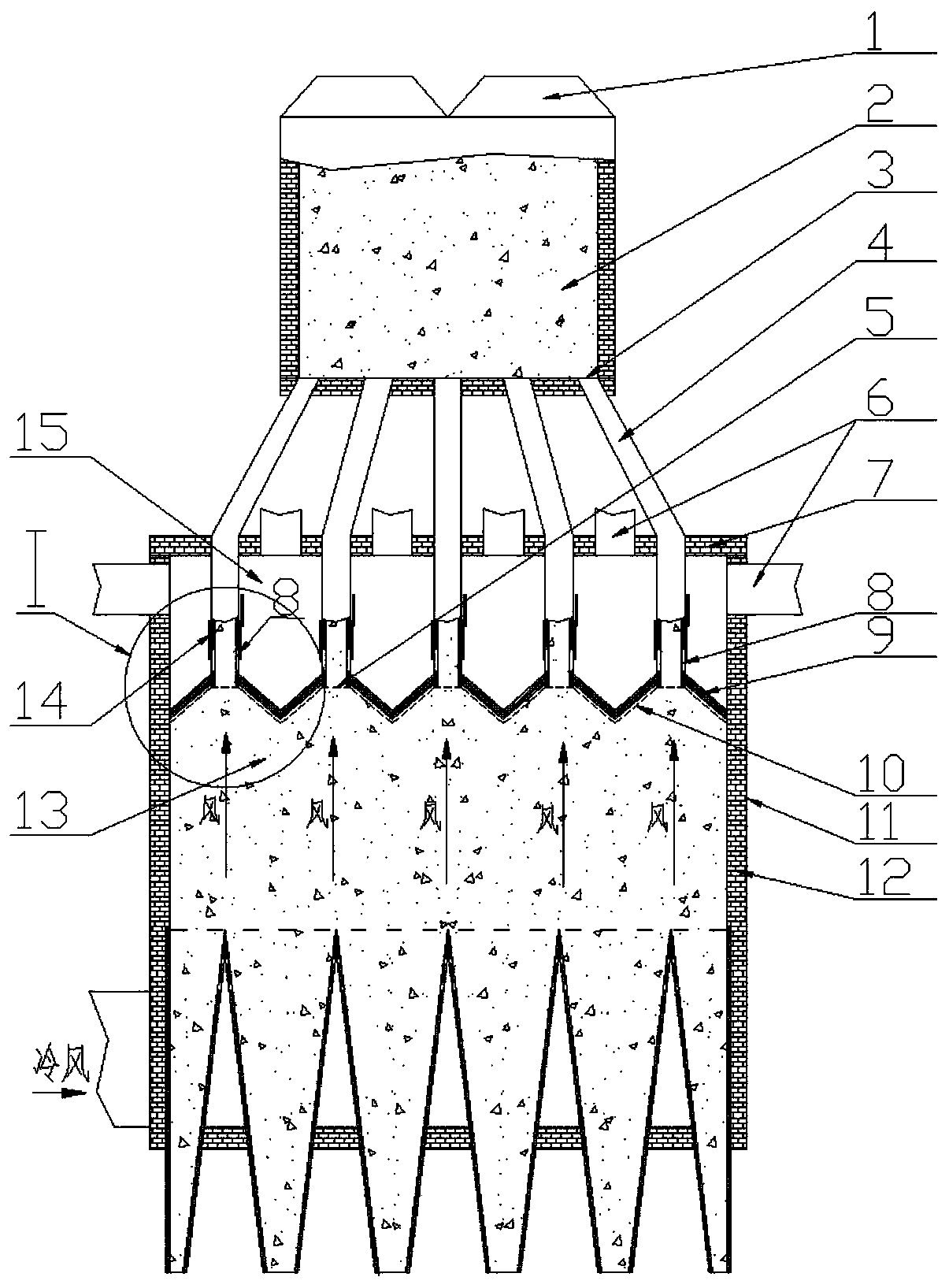

[0060]The vertical cooling kiln includes a feed device, a cooling kiln body, a discharge device, an air inlet device, an air outlet device and a control system; the cooling kiln body includes a feed bin 2, a heat exchange bin 11 and a material transfer pipe 4 , the feeding bin 2 is located above the heat exchanging bin 11, and at least one feed pipe 4 is located between the feeding bin 2 and the heat exchanging bin 11 and communicated; the bottom of the feeding bin 2 and the heat exchanging bin 11 The roof shares a partition, or the two are arranged independently; the heat exchange chamber 11 is a cylinder structure mainly surrounded by the roof 7 and the kiln wall 12, and the inner cavity of the heat exchange chamber 11 is the kiln chamber 13; At least one feeding port 1 is arranged on the top of the warehouse 2; the material transfer pipe 4 extends into the heat exchange chamber 11 for a predetermined length; during operation, the high-temperature mineral material passes thro...

Embodiment 2

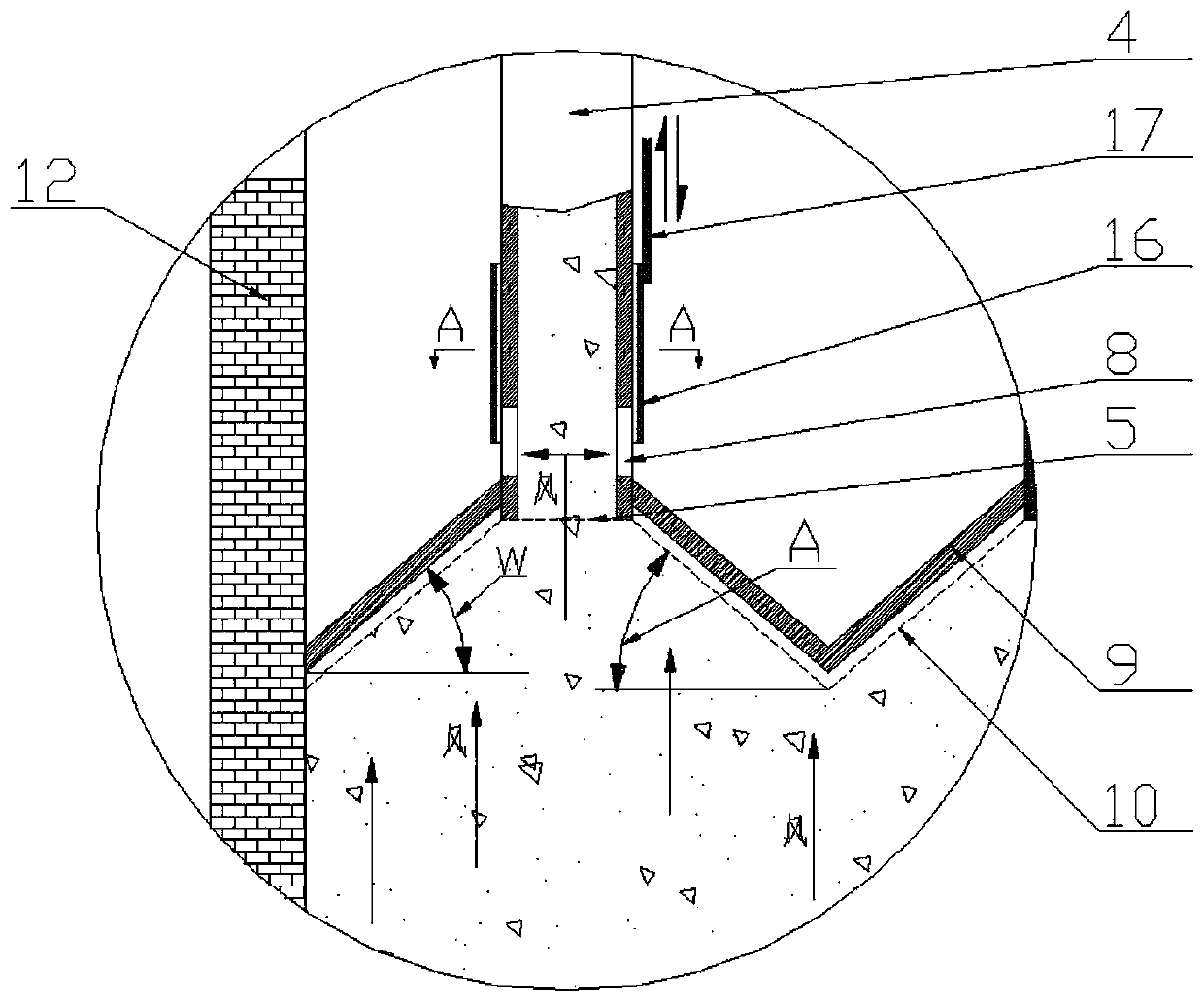

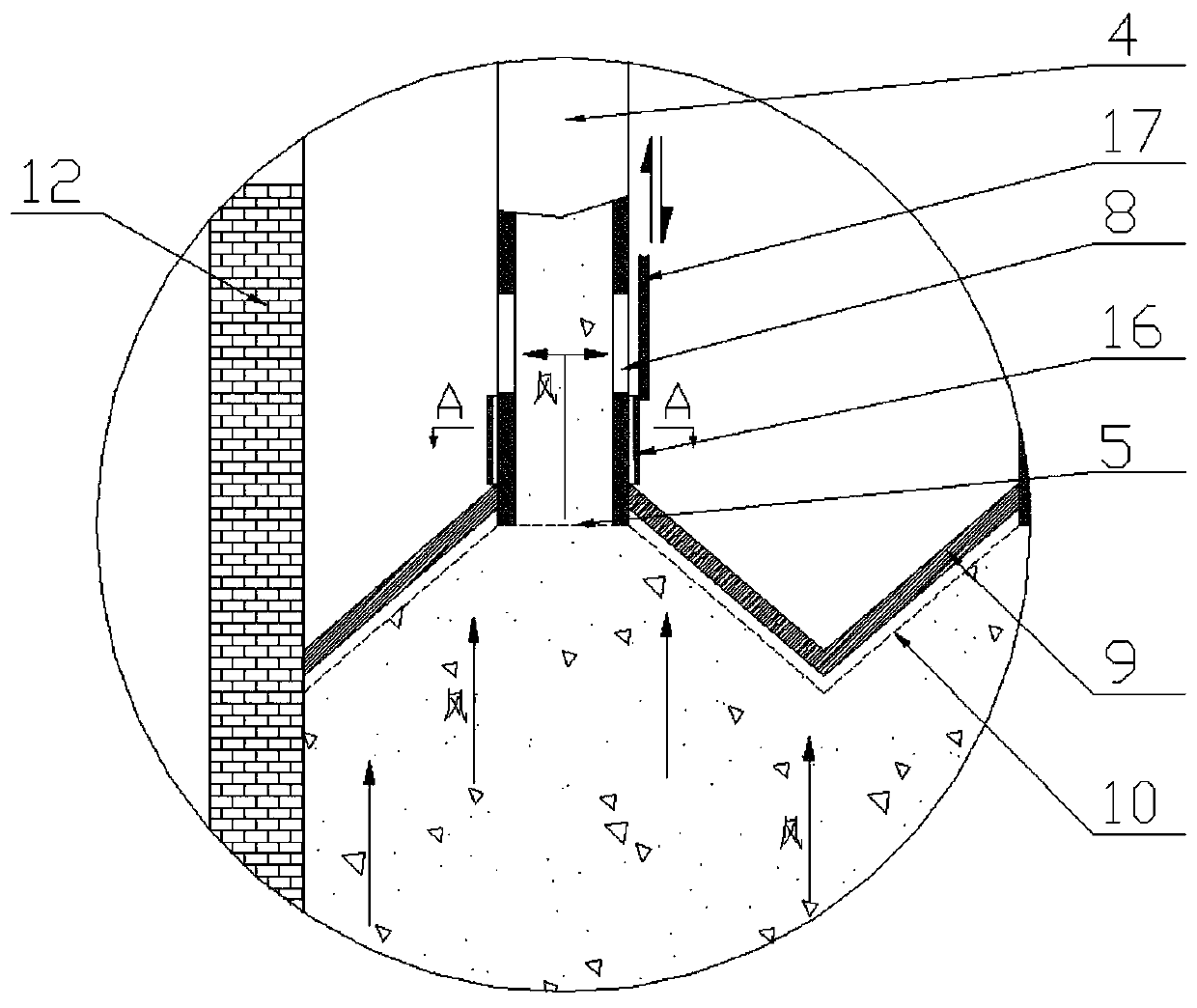

[0069] It is basically the same as Embodiment 1, except that the hot ore air distribution plate 9 is profilingly arranged according to the concave-convex shape of the hot ore top surface 10, and any point on the lower surface of the hot ore air distribution board 9 is in contact with the hot ore top surface 10. The vertical distance is that H is less than 200 centimeters, preferably H is less than 50 centimeters, more preferably H is less than 3 centimeters; or the inclination angle W of the lower surface of the hot ore uniform air plate 9 is not less than the angle A between the generatrix of the hot ore top surface 10 and the horizontal plane , that is, W is not less than the angle of repose A of the high-temperature mineral material; the lower surface of the hot ore uniform air plate 9 can be lower than the hot ore top surface 10 when the hot ore uniform air plate 9 is not set; the hot ore uniform air plate 9 and The kiln wall 12 and the feed pipe 4 are all sealed and connec...

Embodiment 3

[0071] It is basically the same as Embodiment 1 or 2, the difference is that the air regulating component of the JY1 type uniform ventilation device adopts one or a combination of the following structures:

[0072] JY101: The air adjustment assembly includes a movable air adjustment plate 16 and an actuator; the movable air adjustment plate 16 is a plate-shaped or ring-shaped structure, which is arranged on the outside of the material transfer pipe 4, above the air outlet 8, and is connected with the air outlet 8. The actuator is connected; during work, under the action of the actuator, the movable air regulating plate 16 moves up and down to change the ventilation area of the air outlet 8;

[0073] JY102: The air adjustment assembly includes a movable air adjustment plate 16 and an actuator; the movable air adjustment plate 16 is a plate-shaped or ring-shaped structure, which is arranged on the outside of the material transfer pipe 4, below the air outlet 8, and is connected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com