Inductance type magnetic nanometer material sensor and manufacturing method

A magnetic nanometer and magnetic nanoparticle technology, applied in the direction of material impedance, can solve problems such as equipment stoppage, mechanical failure, loss, etc., and achieve the effect of high discrimination, simple operation and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

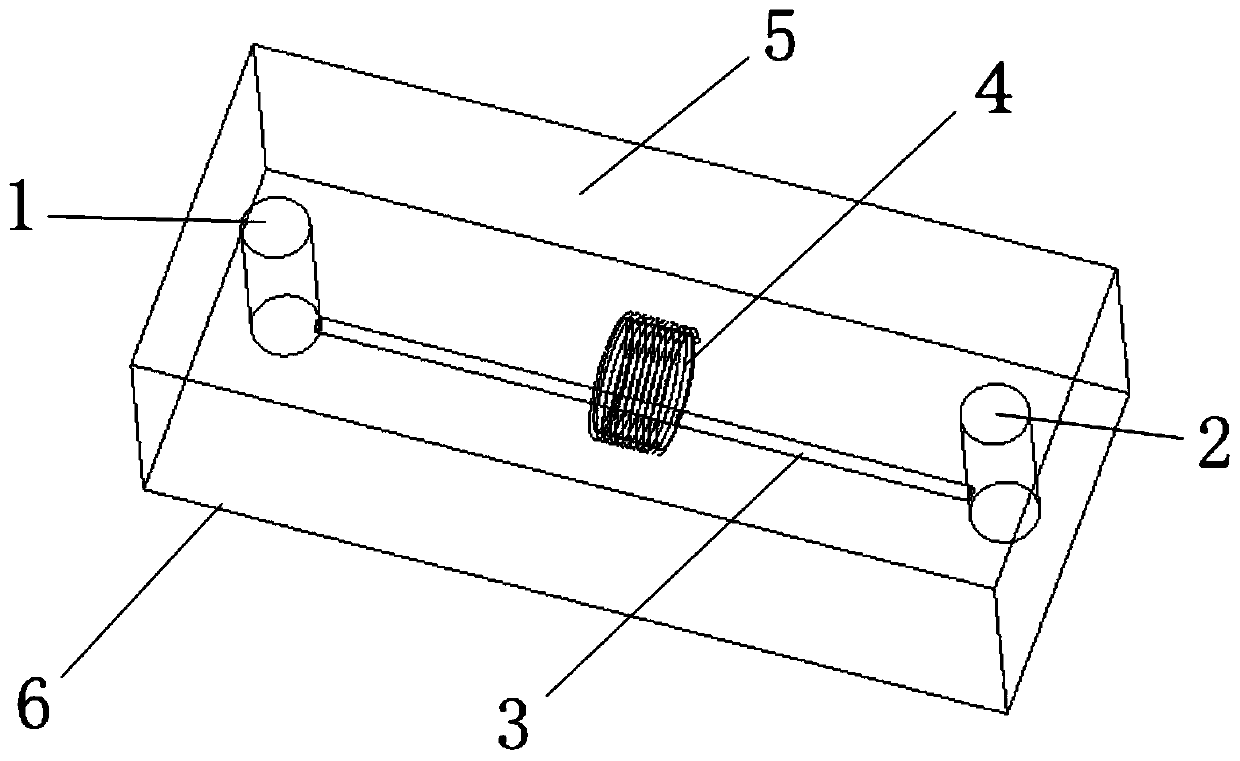

[0042] As a preferred embodiment of the present invention, the use process of the inductive magnetic nanomaterial sensor of the present invention is as follows:

[0043] Step 1: Transport the oil to be detected to the microchannel 3 through the oil inlet 1;

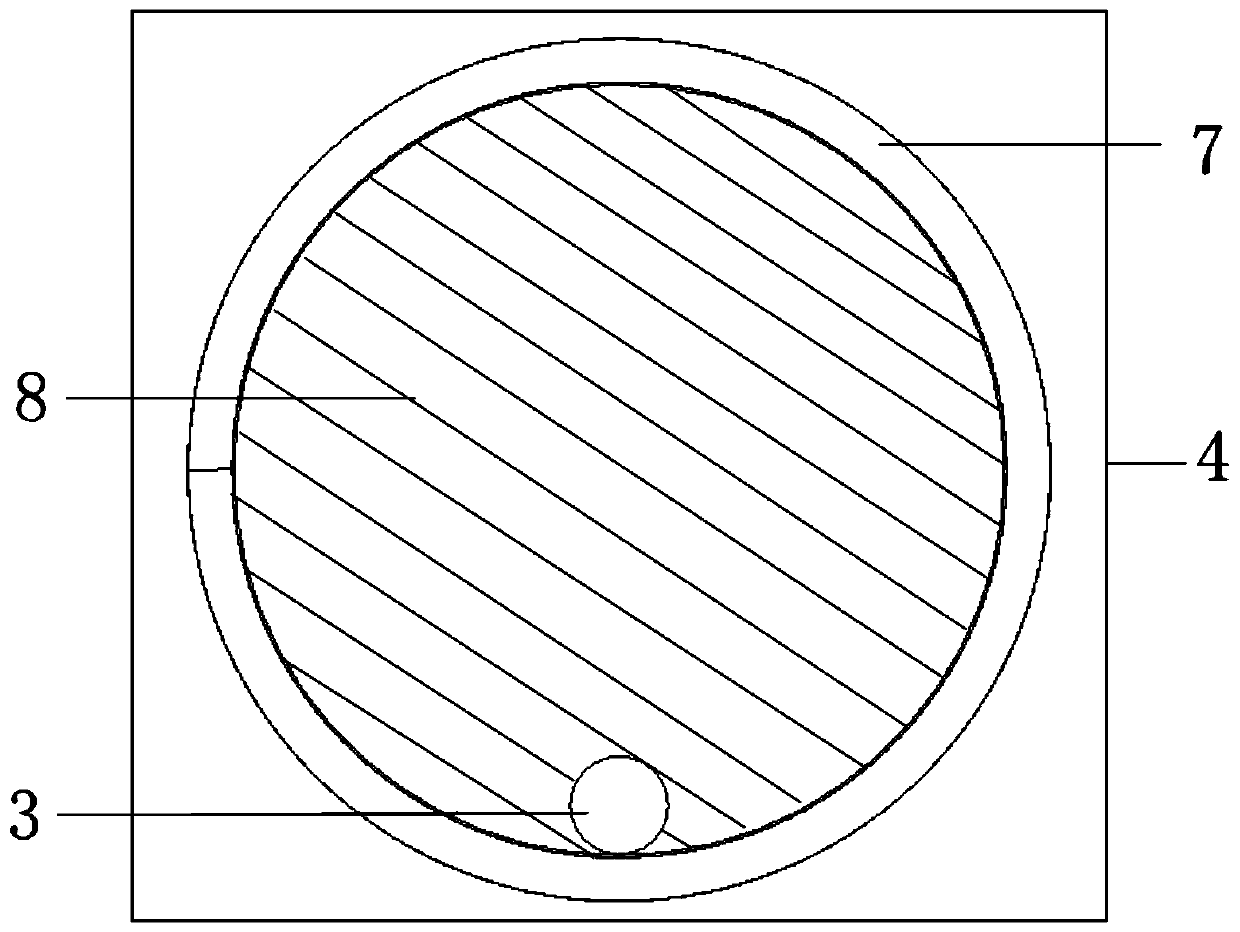

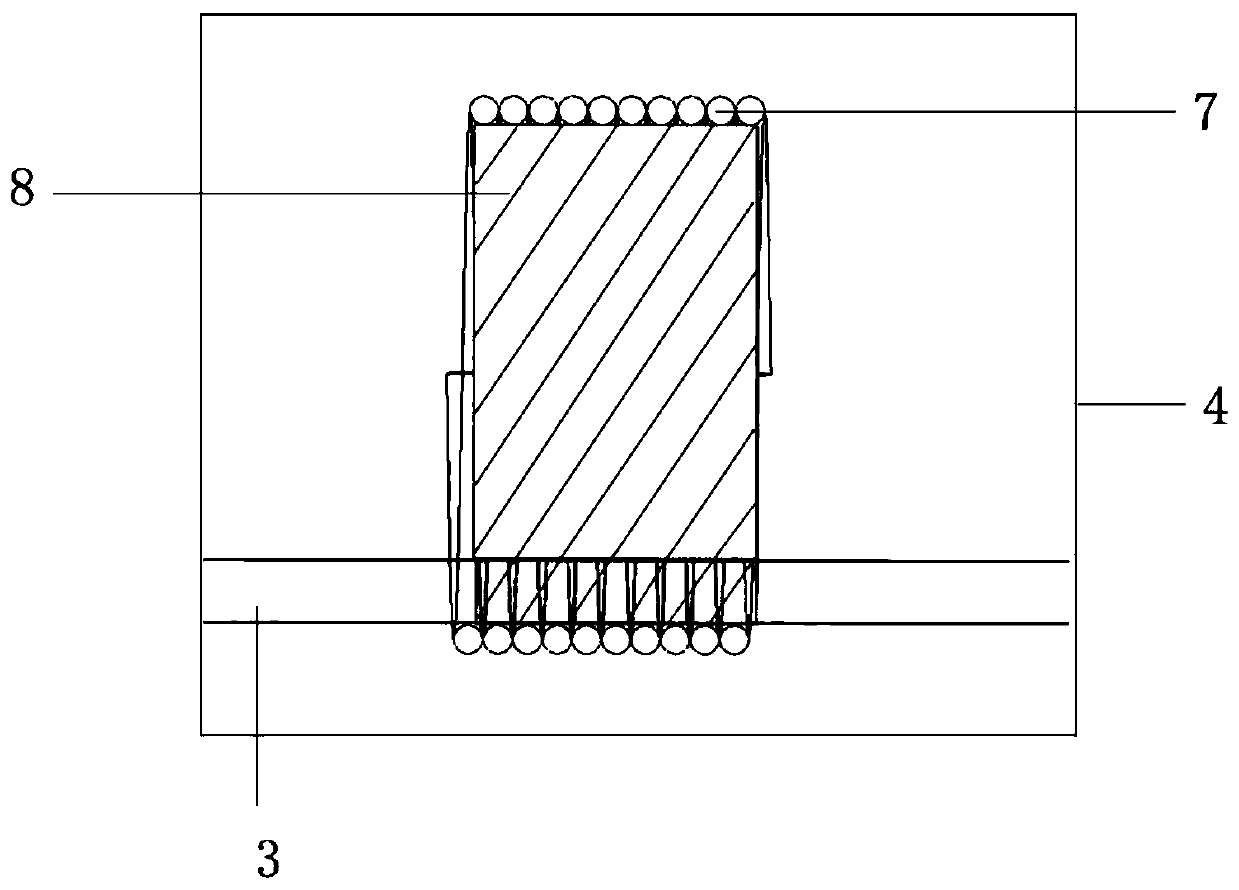

[0044] Step 2: The oil to be detected flowing through the sensing unit 4 is stimulated by a high-frequency signal through the sensing unit 4, and the detection of particle pollutants in the oil is distinguished and detected according to the detection results; Figure 4 As shown, when the sensor detects metal abrasive grains, the abrasive grains will be magnetized in the alternating magnetic field generated by the solenoid coil, and a new magnetic field will be generated after the ferromagnetic particles are magnetized. The direction is consistent with the coil magnetic field, and the detected inductance signal shows upward increase; such as Figure 5 As shown, when non-ferromagnetic particles pass through, the eddy curre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com