A rapid calibration and correction method and a TOF camera thereof

A TOF camera and correction method technology, applied in the camera field, can solve problems such as high variable dimension, error, overexposure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

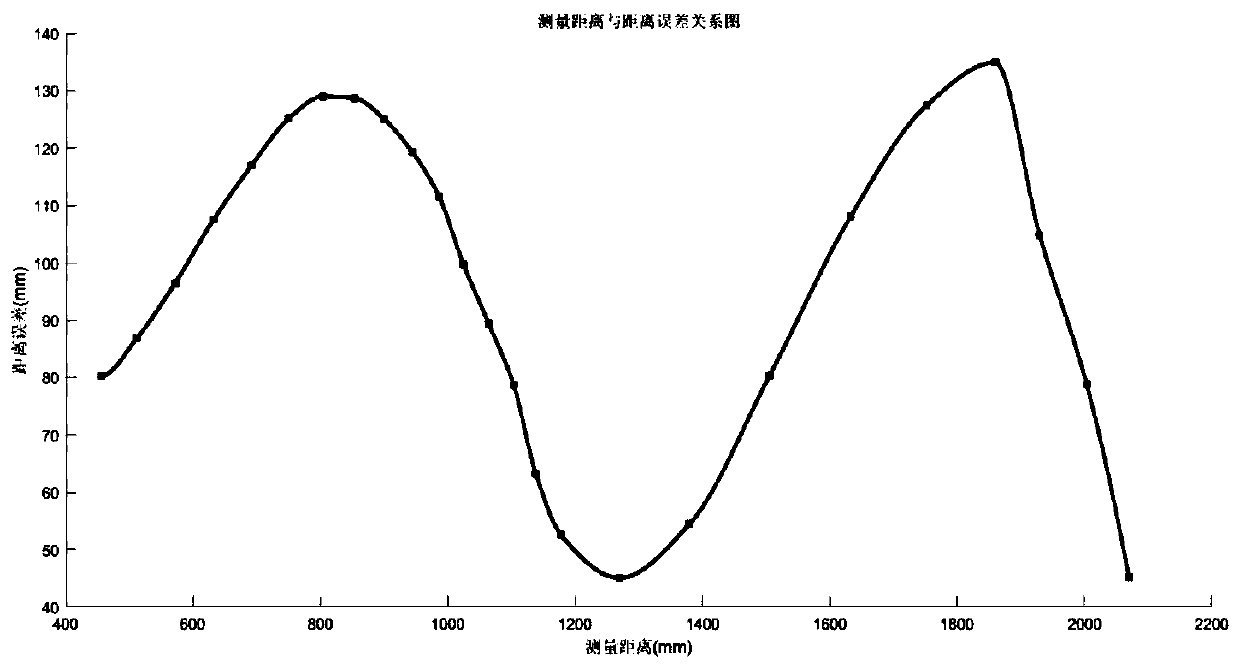

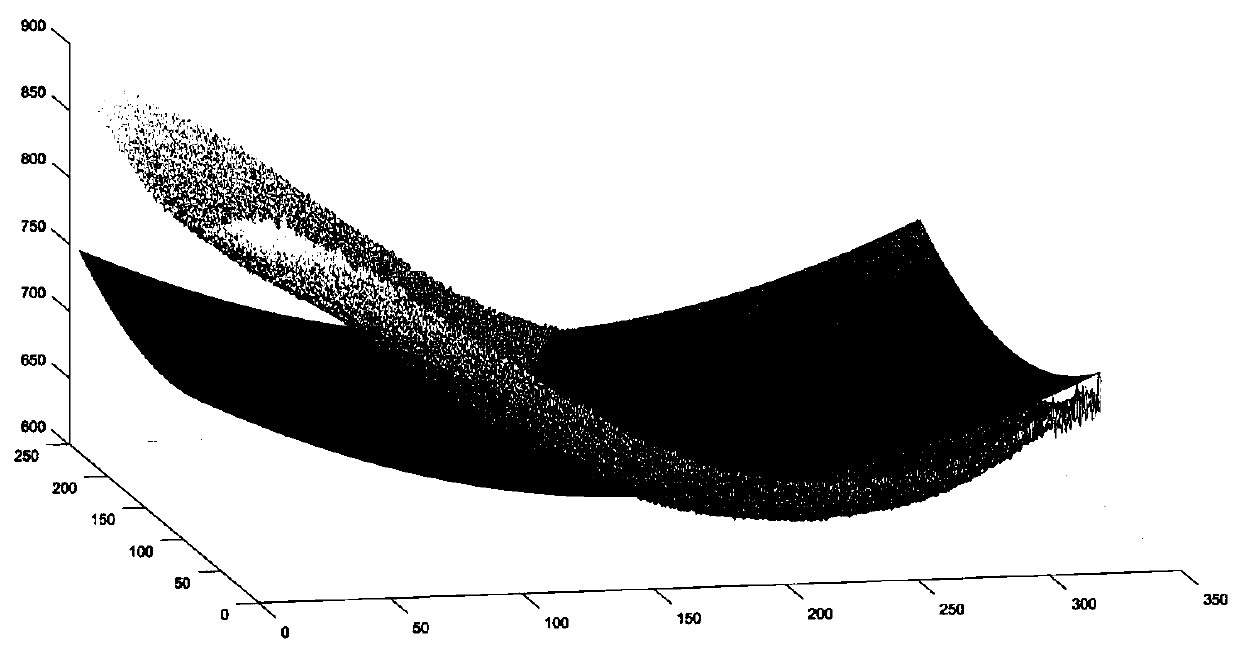

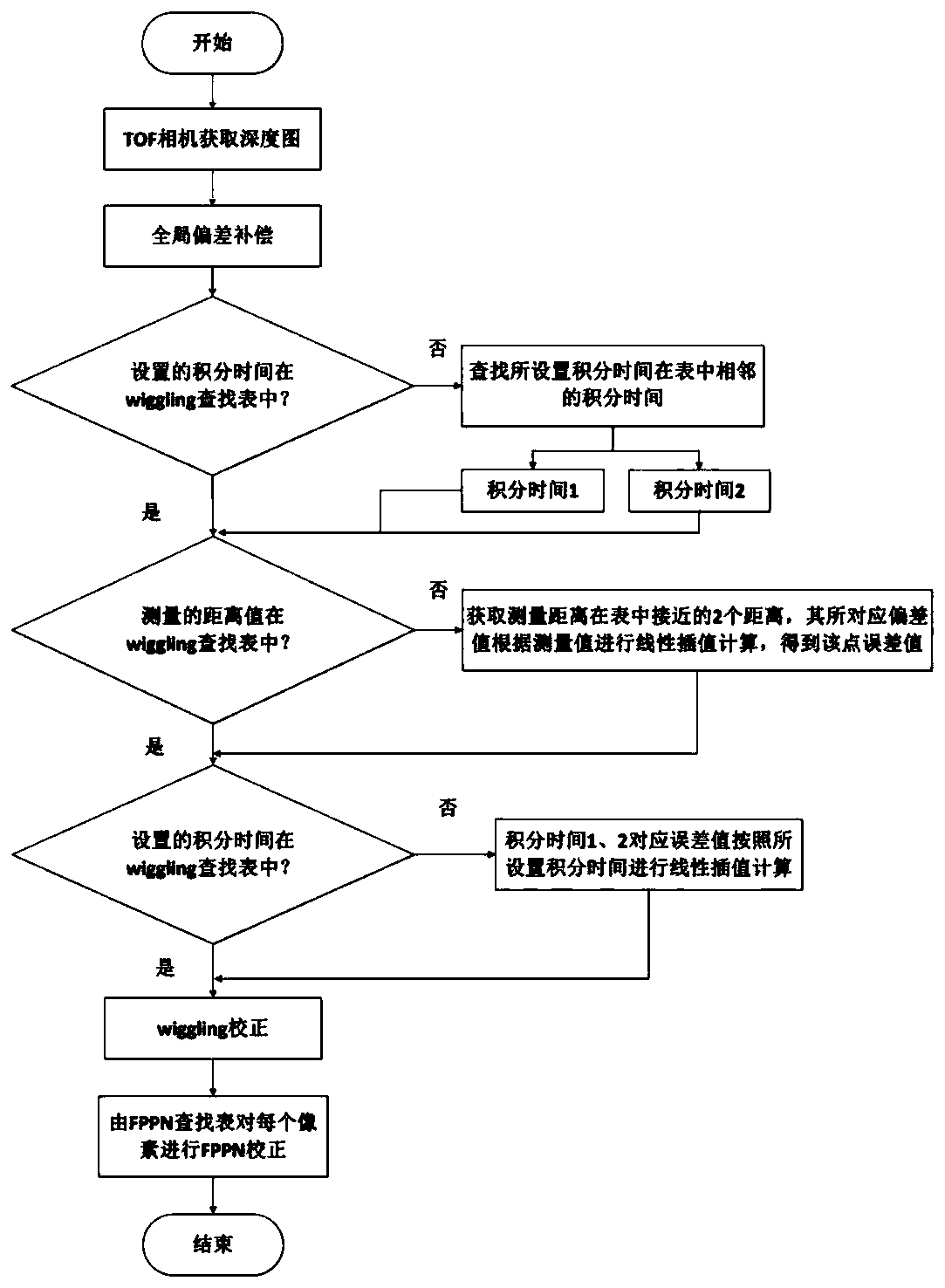

[0049] Such as Figure 1-3 Shown, a kind of rapid calibration and correction method is characterized in that: comprises the following steps:

[0050] Step 1: Collect relevant data of the TOF camera at a fixed frequency of 40MHz, including depth value images, integration time values, and real distance value data;

[0051] Step 2: Process the data obtained in step 1 to generate relevant calibration parameters, including global deviation values, wiggling lookup tables, and FPPN lookup tables;

[0052] Step 3: According to the relevant calibration parameters generated in step 2, perform distance correction on the TOF camera, including preprocessing, wiggling correction, and FPPN correction.

[0053] The resolution of the TOF camera adopted in the step 1 is 240*320;

[0054] Gathering relevant data of TOF camera in described step 1 comprises the following steps:

[0055] (1a) Set the TOF camera integration time to the minimum integration time of 50us.

[0056] (1b) The integrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com