Metal oxide lightening arrester with detachable composite outer sleeve

A composite jacket and oxide technology, applied in resistors, resistor parts, overvoltage protection resistors, etc., can solve the problems of inability to recycle the composite jacket, unable to remove the composite jacket, and reduce the effect of the arrester. Convenience, improve moisture-proof efficiency, avoid the effect of daily work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

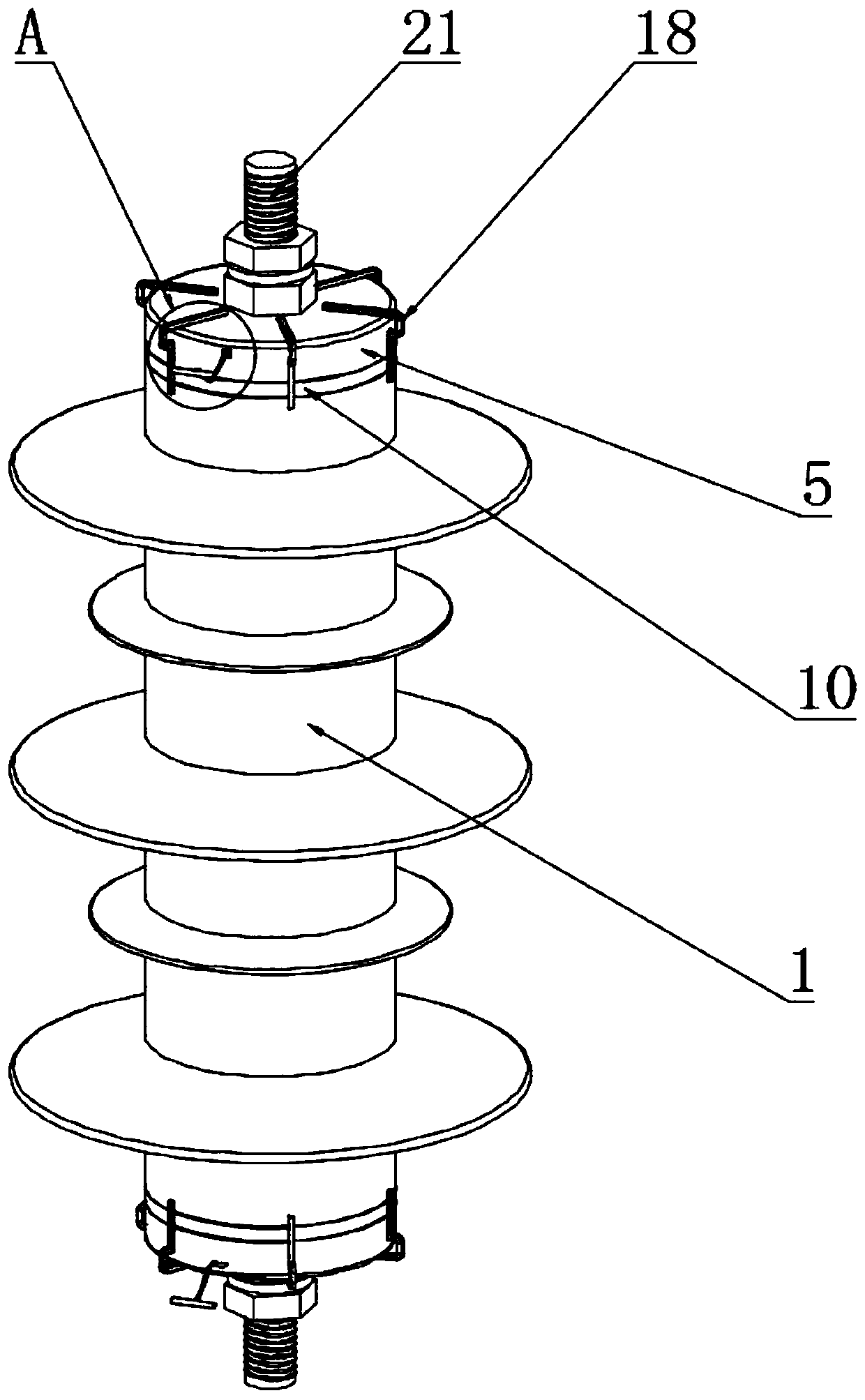

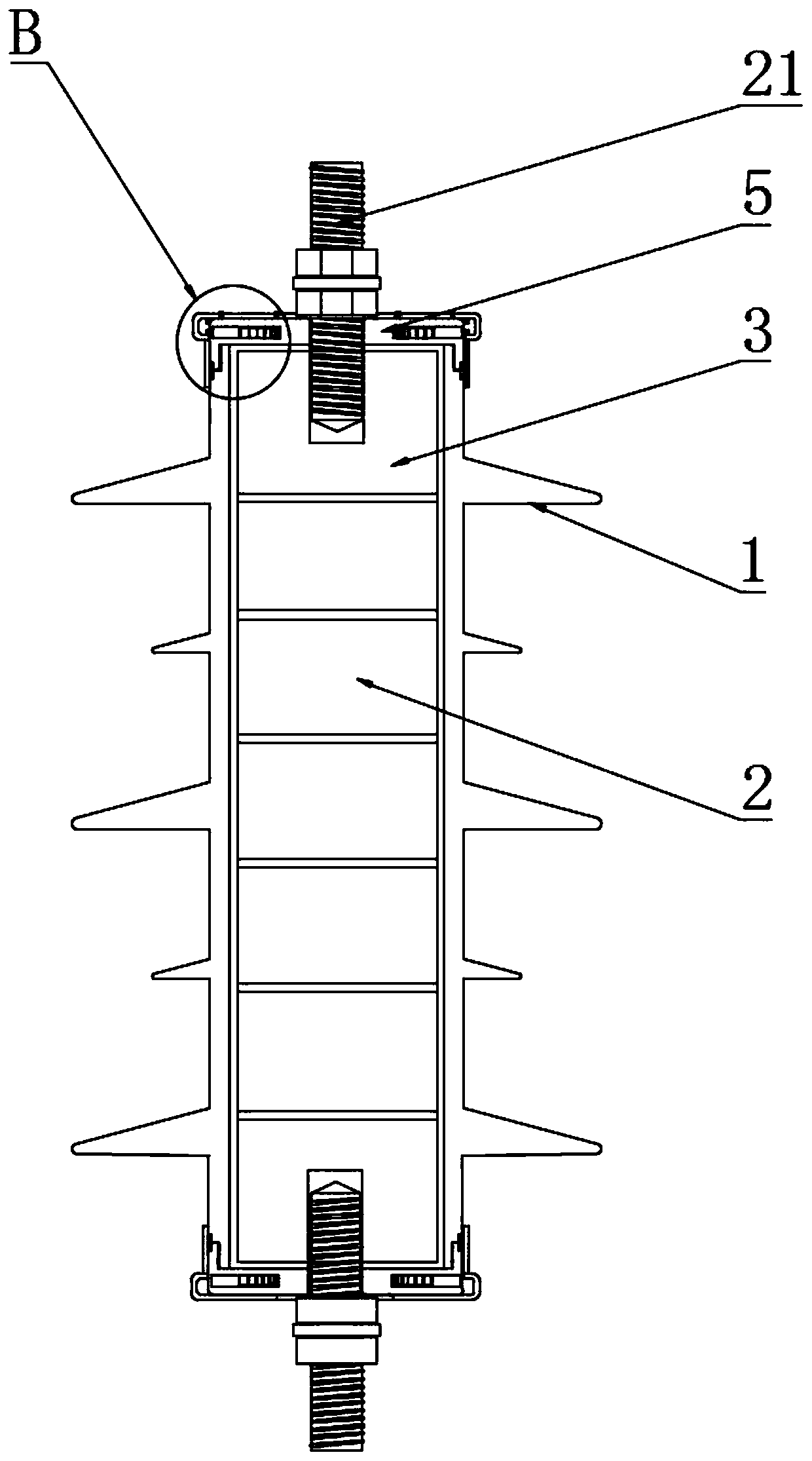

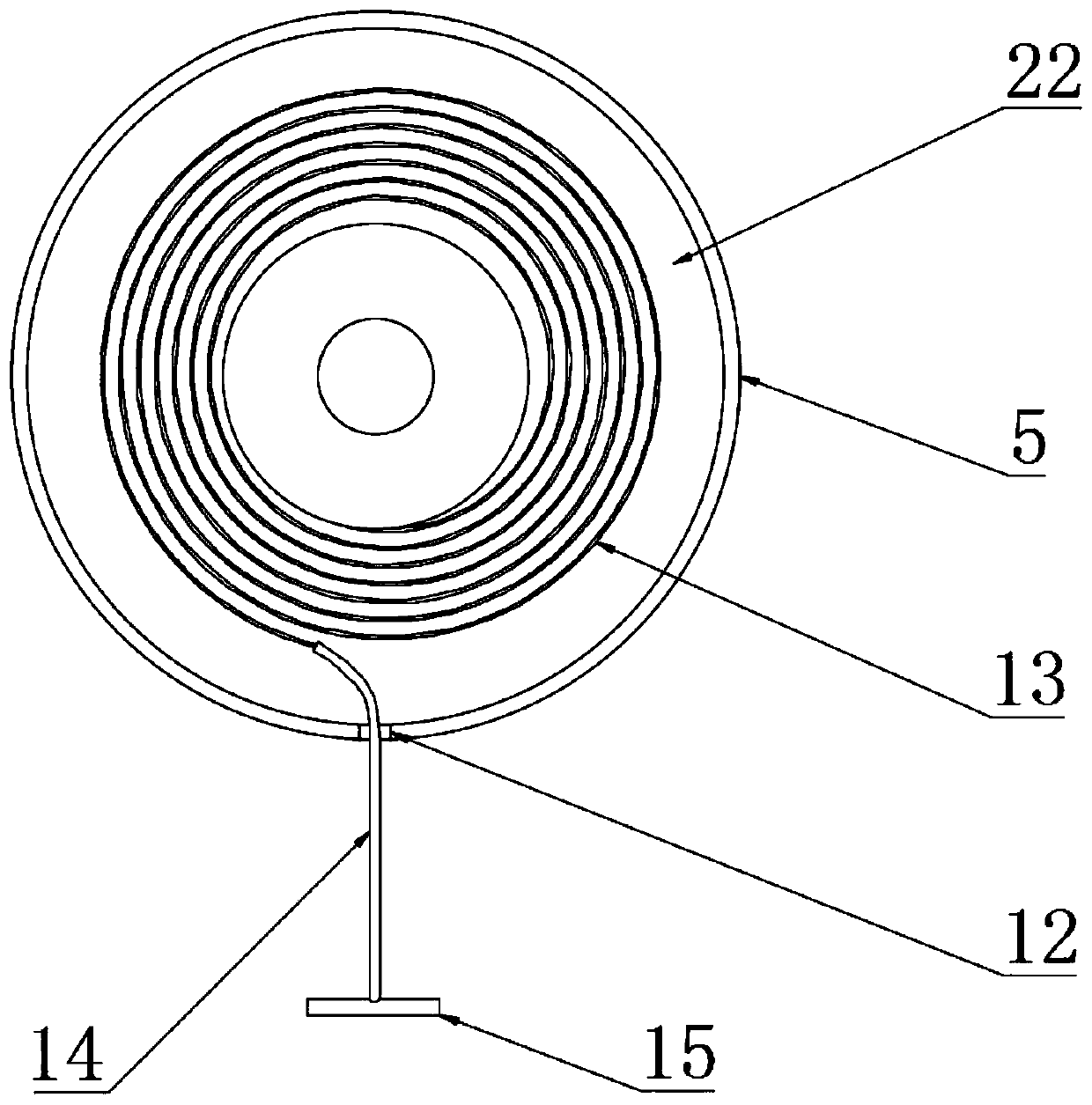

[0027] Example: such as Figure 1-5 As shown, the present invention provides a technical solution, a detachable composite jacket metal oxide arrester, including a composite jacket 1, a resistor module 2 is wrapped inside the composite jacket 1, and terminal blocks are provided at the top and bottom of the resistor module 2 3. The outer surface of the top and bottom of the composite jacket 1 is provided with external connecting threads 4, the top and bottom of the composite jacket 1 are installed with end caps 5, and the middle parts of the two end caps 5 are installed with connecting terminals 21, and the inside of the end cap 5 Internal connecting threads 6 are provided on the surfaces, and the composite outer casing 1 and the end cap 5 are detachably connected by tooth engagement between the internal connecting threads 6 and the external connecting threads 4 .

[0028] The outer surface of the bottom of the end cover 5 at the top of the composite jacket 1 and the outer surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com