Forming method of three-dimensional memory device, and three-dimensional memory device

A three-dimensional storage and device technology, applied in semiconductor devices, electrical solid devices, electrical components, etc., can solve problems such as device defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Based on the above-mentioned problems in the related art, the embodiment of the present application provides a method for forming a three-dimensional memory device, which adopts the method of separately etching channel holes and DCHs on the upper stack layer and the lower stack layer to form a double-layer three-dimensional memory device . While ensuring the upper channel hole and the lower channel hole of the double-layer three-dimensional memory device, the etching difficulty of the DCH is improved, and the etching depth of the DCH is reduced, thereby avoiding the problem of device defects and reducing the difficulty of the process.

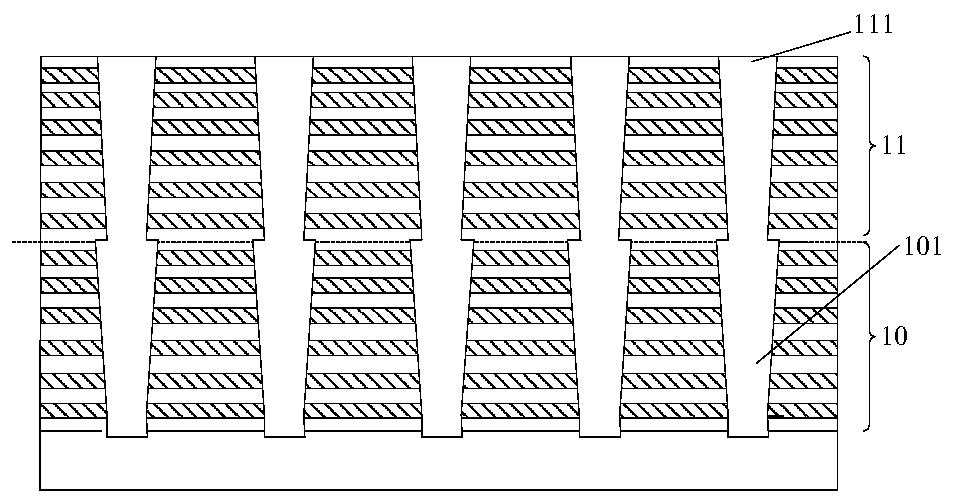

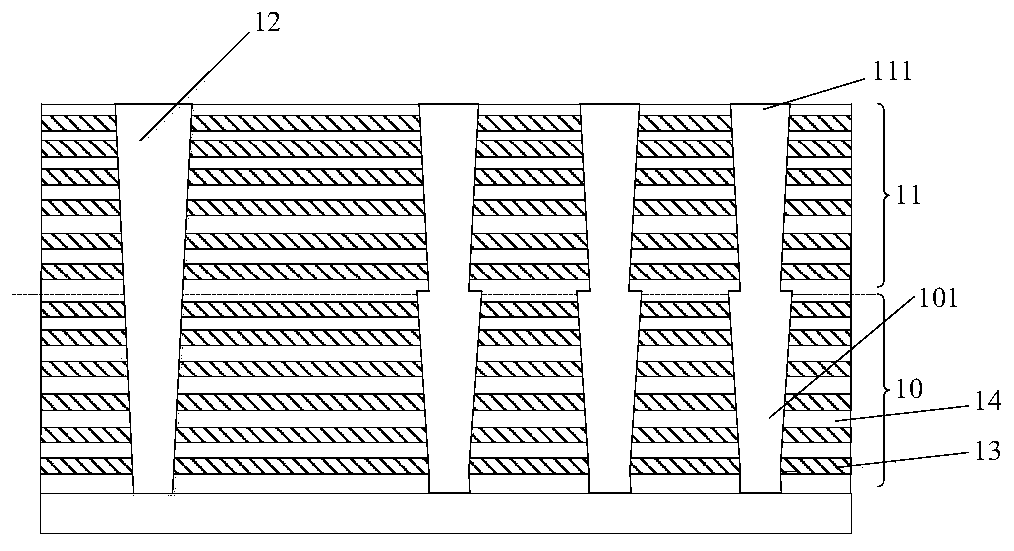

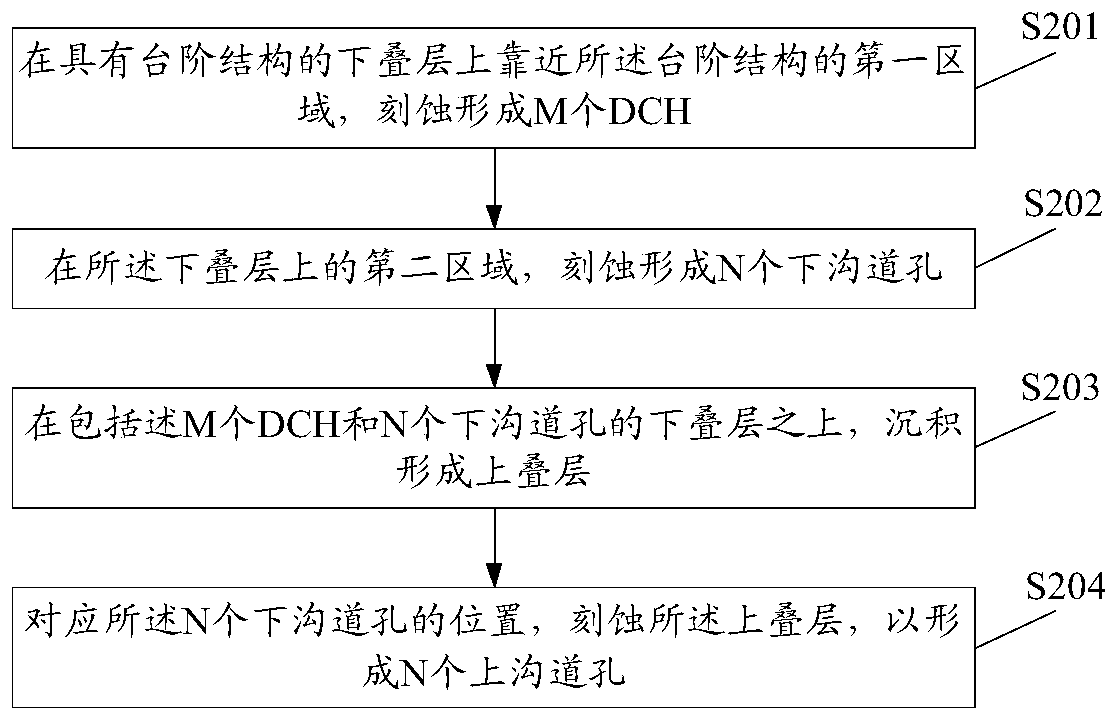

[0067] figure 2 It is a schematic flow diagram of a method for forming a three-dimensional storage device according to an embodiment of the present application, as shown in figure 2 As shown, the method includes the following steps:

[0068] Step S201 , forming M DCHs by etching in a first region close to the stepped structure on the...

Embodiment 2

[0091] An embodiment of the present application provides a method for forming a three-dimensional memory device, Figure 4 It is a schematic diagram of the implementation flow of another method for forming a three-dimensional storage device according to the embodiment of the present application, as shown in Figure 4 As shown, the method includes the following steps:

[0092] In step S401, the first material layer and the second material layer are stacked circularly on the substrate to form a lower stacked layer; the lower stacked layer is etched so that the lower stacked layer has a stepped structure.

[0093] Such as Figure 5A As shown, on the substrate 51 , after stacking the first material layer 501 and the second material layer 502 cyclically, the lower stacked layer is etched to form the lower stacked layer 52 with the stepped structure 521 .

[0094] Here, the substrate 51 is located at the lowest layer of the three-dimensional memory device, and the material of the ...

Embodiment 3

[0148] An embodiment of the present application provides a method for forming a three-dimensional memory device, Image 6 It is a schematic flow diagram of another method for forming a three-dimensional storage device in the embodiment of the present application, as shown in Image 6 As shown, the method includes the following steps:

[0149] In step S601 , according to a second preset stacking rule, the first material layer and the second material layer are stacked circularly on the substrate to form the lower stacked layer with a stepped structure.

[0150] Such as Figure 7A As shown, on the substrate 71 , the first material layer 701 and the second material layer 702 are stacked circularly to form the lower layer 72 with the stepped structure 721 .

[0151] Here, the second preset stacking rules include the following two types:

[0152] The first type, according to the same stacking pattern, the area of each first material layer is larger than the area of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com