Soup mixing control system and method

A control system and controller technology, applied in applications, cooking utensils, household appliances, etc., to achieve the effects of ensuring diversity, reducing labor costs, and improving soup mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

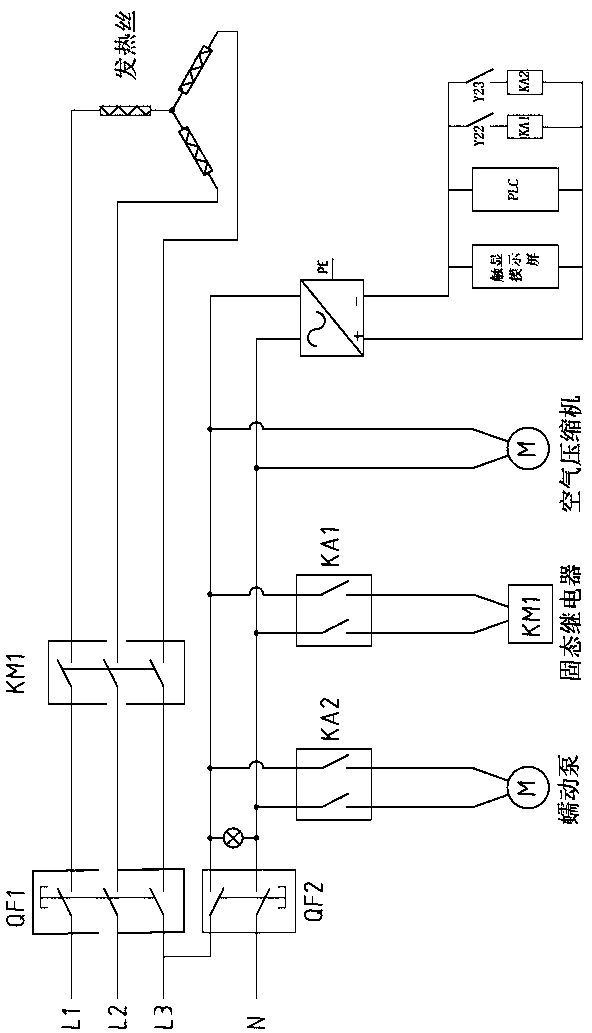

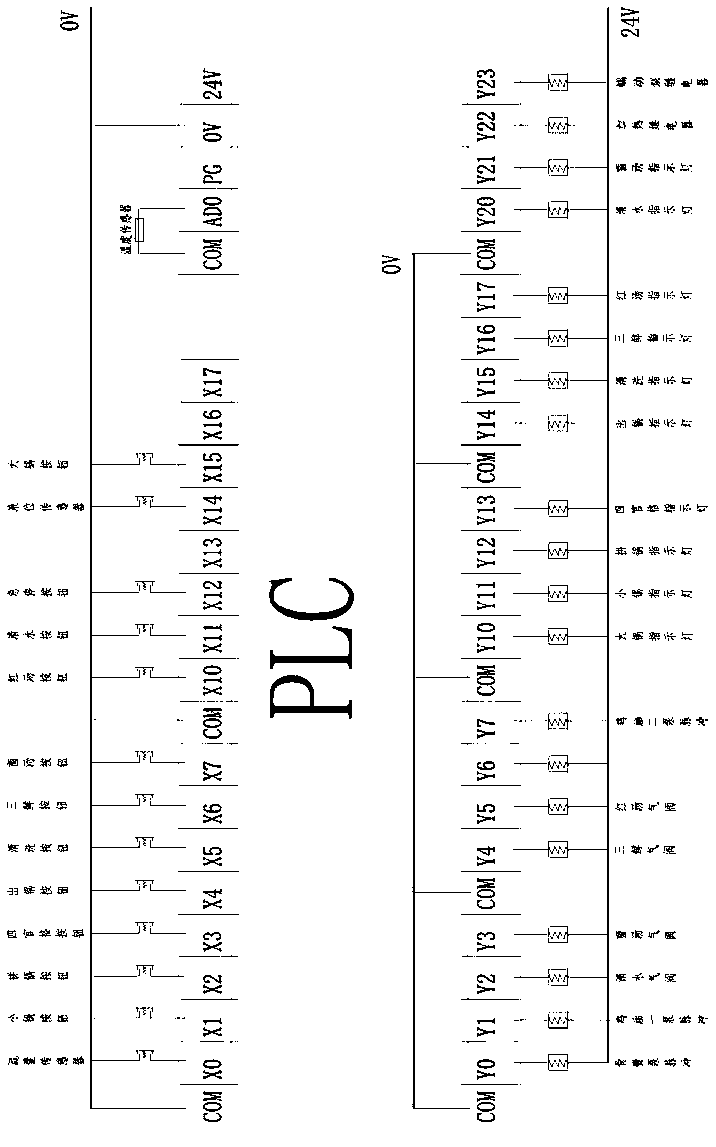

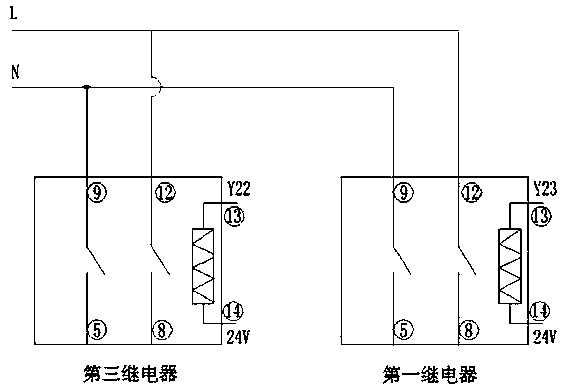

[0042] The control system used to adjust the soup in this embodiment includes a power switch, a touch screen, a control button, a PLC controller, a peristaltic pump (a stepper motor in this embodiment), an air compressor, and a heating wire (in this embodiment The rated power of the middle heating wire is 9kw), the intermediate relay KA1 used to control the peristaltic pump, the intermediate relay KA2 used to control the air compressor, and the solid state relay KM1 used to control the heating wire. The intermediate relay KA1, the intermediate relay KA2, and the solid-state relay KM1 are respectively electrically connected to the PLC controller; the power switch controls the switching on and off of the current; Electrically connected, input control parameters through the touch screen, send control instructions to the PLC controller, and then complete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com