Machining method of low-eccentric-error dual inner conical face positioning block

A processing method and the technology of the inner cone surface are applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., and can solve problems such as decreased positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

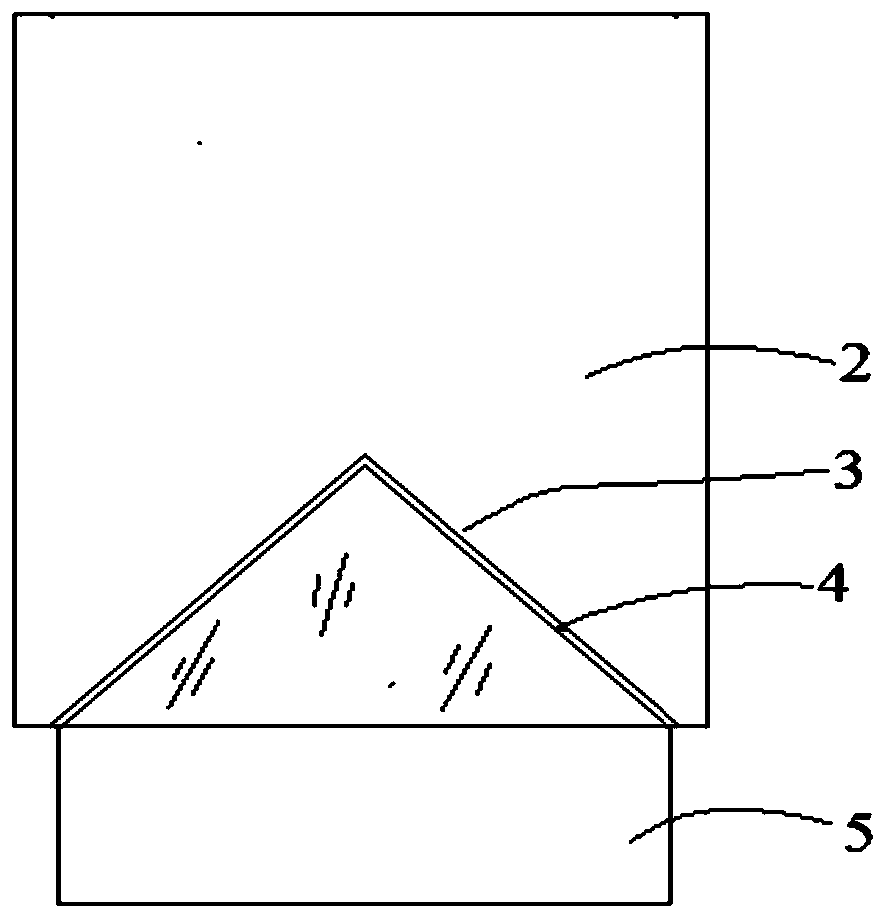

[0022] A processing method of double inner cone positioning block with low eccentricity difference, such as Figure 5 As shown, the positioning block is composed of a first inner cone surface 3 and a second inner cone surface 1 machined on two end faces of the positioning block 2, which in turn includes the following steps:

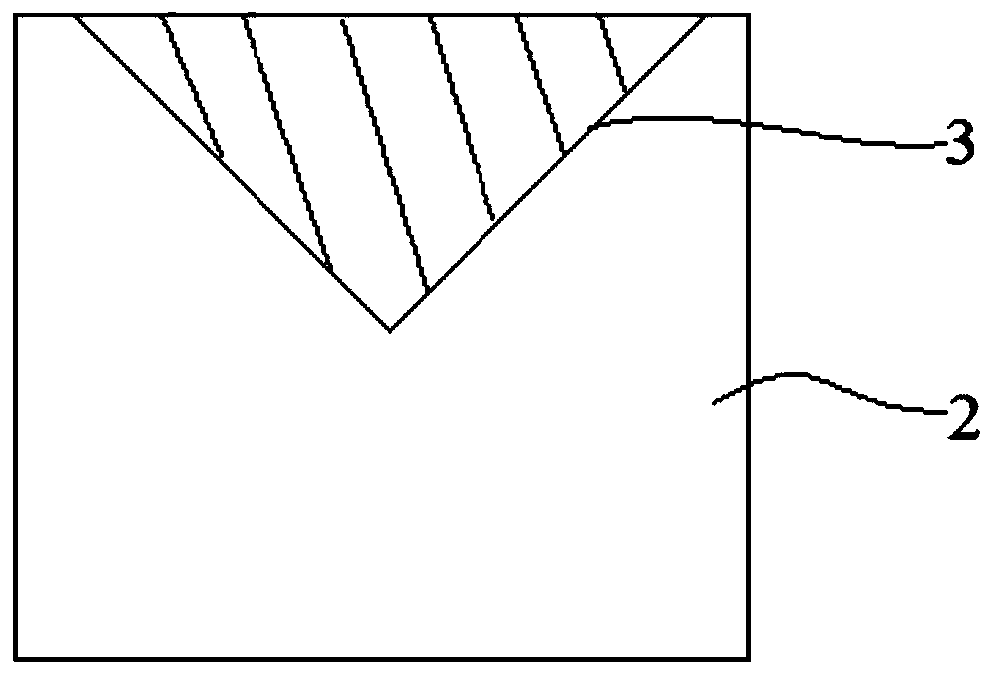

[0023] Clamp the positioning block on the machine tool turntable, such as figure 1 As shown, the first inner cone surface is processed on the end surface of the positioning block;

[0024] Remove the positioning block for processing the first inner cone surface from the machine tool;

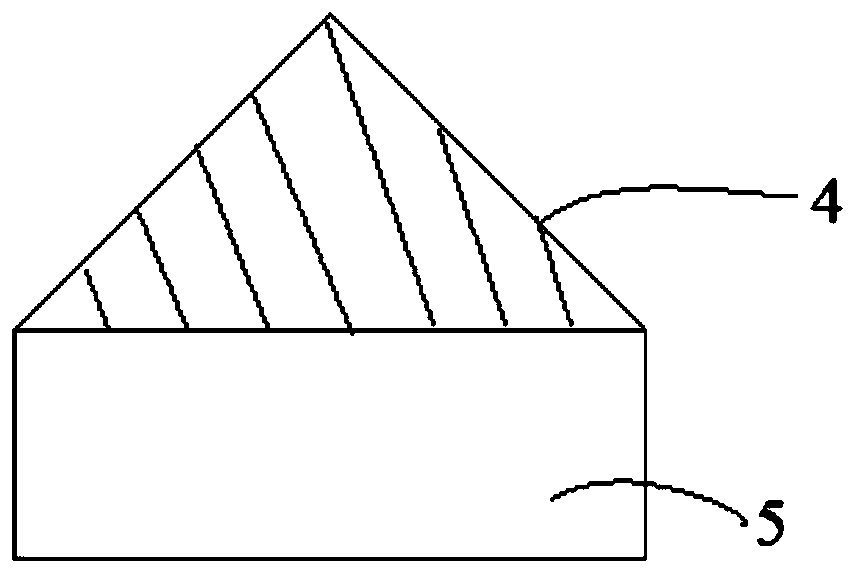

[0025] Clamp the auxiliary block on the turntable of the machine tool, and machine the end surface of the auxiliary block into an outer cone 4, such as figure 2 Shown

[0026] Such as image 3 As shown, the outer cone surface of the auxiliary block is fixedly assembled with the first inner cone surface of the positioning block, and the second inner cone surface 1 is machined on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com