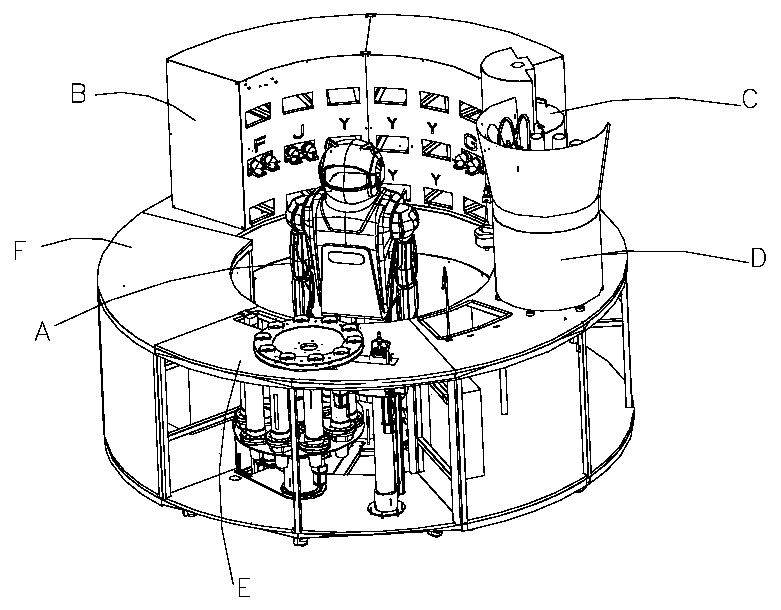

Automatic tea beverage preparation bar counter

A technology for automatic preparation and tea beverages, applied in beverage preparation devices, manufacturing tools, program-controlled manipulators, etc., can solve the problems that the taste cannot be completely unified and stable, and the cost of tea beverages is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Such as Figure 7 Figure 8 The connecting nozzle shown includes an air inlet D101, the lower end of the air inlet D101 is connected to the seat cover D102, the air inlet D101 and the seat cover D102 are provided with a central air inlet channel D103, and the lower bottom surface of the seat cover D102 is provided for The capsule slot D107 of the card and tea capsules has an anti-leakage structure in the capsule slot D107.

[0081] A concave inflatable space D106 is provided in the middle of the capsule groove D107.

[0082] A guide nozzle D104 is inserted in the middle of the inflation space D106, and the upper part of the guide nozzle D104 is provided with a blind hole communicating with the air inlet channel D103.

[0083] The lower part of the guide nozzle D104 is provided with a number of inclined through holes in a circular array. The inclined through holes start at the bottom of the blind hole and finally guide the lower side wall of the nozzle D104.

[0084] The positio...

Embodiment 2

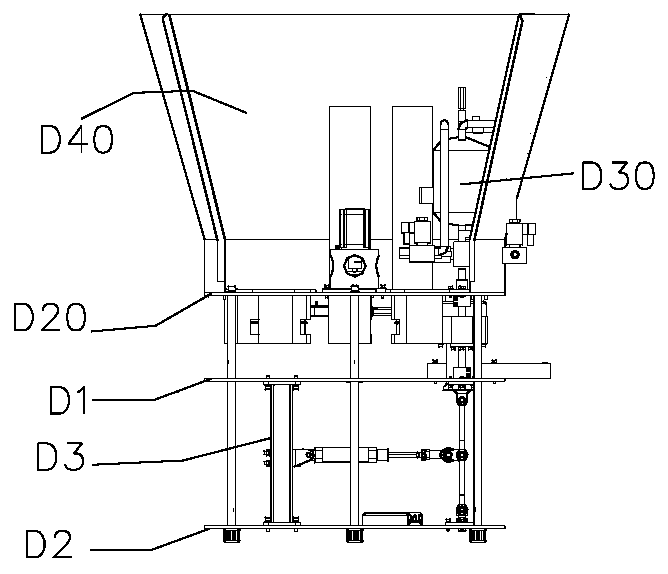

[0091] Such as Figure 7 , The tea taking system shown in 8 includes an upper panel D20. The outer circle of the upper panel D20 has a circle of stations in the outer circle. The outer circle of the upper panel D20 has a station for taking out. The rest of the stations are fixed with tea The tea box tube D508 of the box D503, the lower part of each tea box tube D508 is correspondingly provided with a connected extraction part D5081, the extraction part D5081 is provided at the lower part of the upper panel D20, and the lower part of the upper panel D20 is fixed with a device for taking out the tea box in the extraction part D5081 Extract components.

[0092] The extraction part D5081 includes a horizontal notch through which the tea box can be taken out.

[0093] The extraction assembly includes a horizontal main cylinder D504, and the upper part of the main cylinder is connected and fixed with a main cylinder block D5041.

[0094] The upper end of the main cylinder base D5041 is co...

Embodiment 3

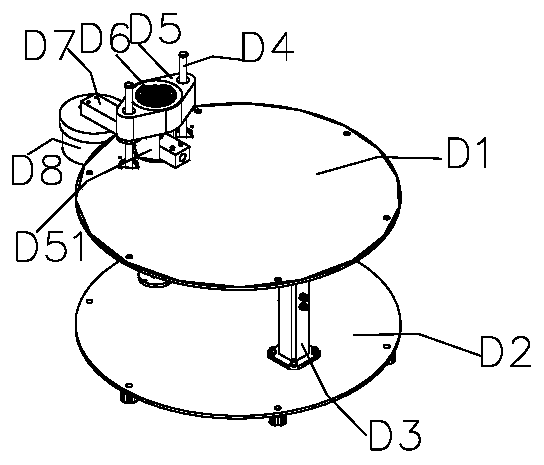

[0101] Such as Figure 3-6 As shown, a liftable extraction head housing D5 is provided above the intermediate plate D1, the extraction head housing D5 has a vertical hollow channel, and the upper part of the hollow channel is provided with a place for placing a tea capsule D6 (ie a tea box), hollow The lower part of the channel is plugged with an extraction head D9 for collecting the extraction liquid, and a driving assembly D3 for driving the extraction head housing D5 up and down is arranged between the middle plate D1 and the bottom plate D2.

[0102] A moving head support cylinder D51 is connected to the lower part of the extraction head housing D5. The moving head support cylinder D51 includes an upper connecting end and a lower connecting end. Two opposite vertical support plates are arranged between the upper connecting end and the lower connecting end.

[0103] The middle plate D1 is provided with a through hole through which the vertical support plate passes.

[0104] Two gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com