Car spare part holder

A technology for accessory clips and automobiles, which is applied to trolleys, motor vehicles, multi-axis trolleys, etc., can solve the problems of high cost, dangerous handling personnel, and unsatisfactory popularization effect of small and medium-sized auto repair shops, so as to save costs and reduce dependence. the effect of improving flexibility and practical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

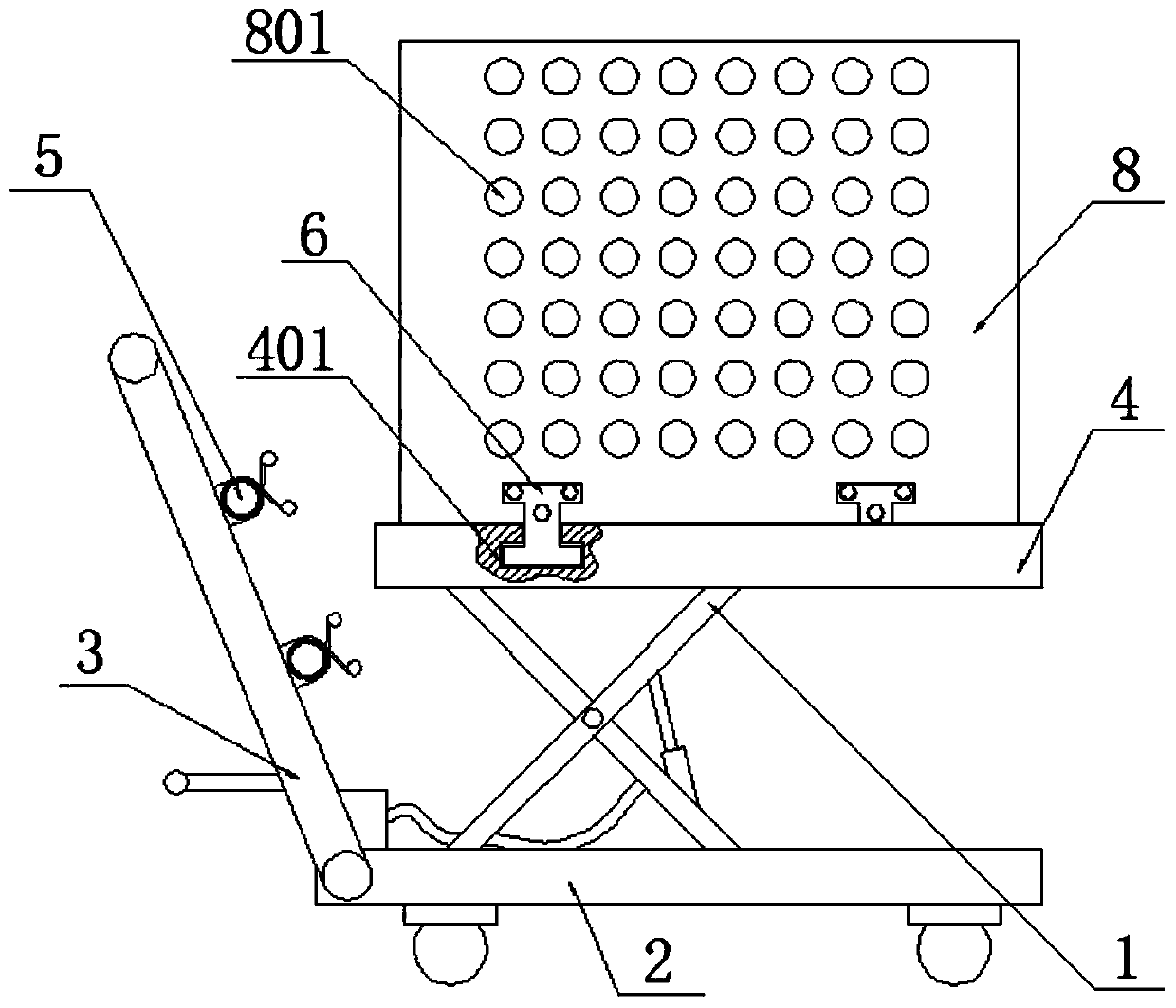

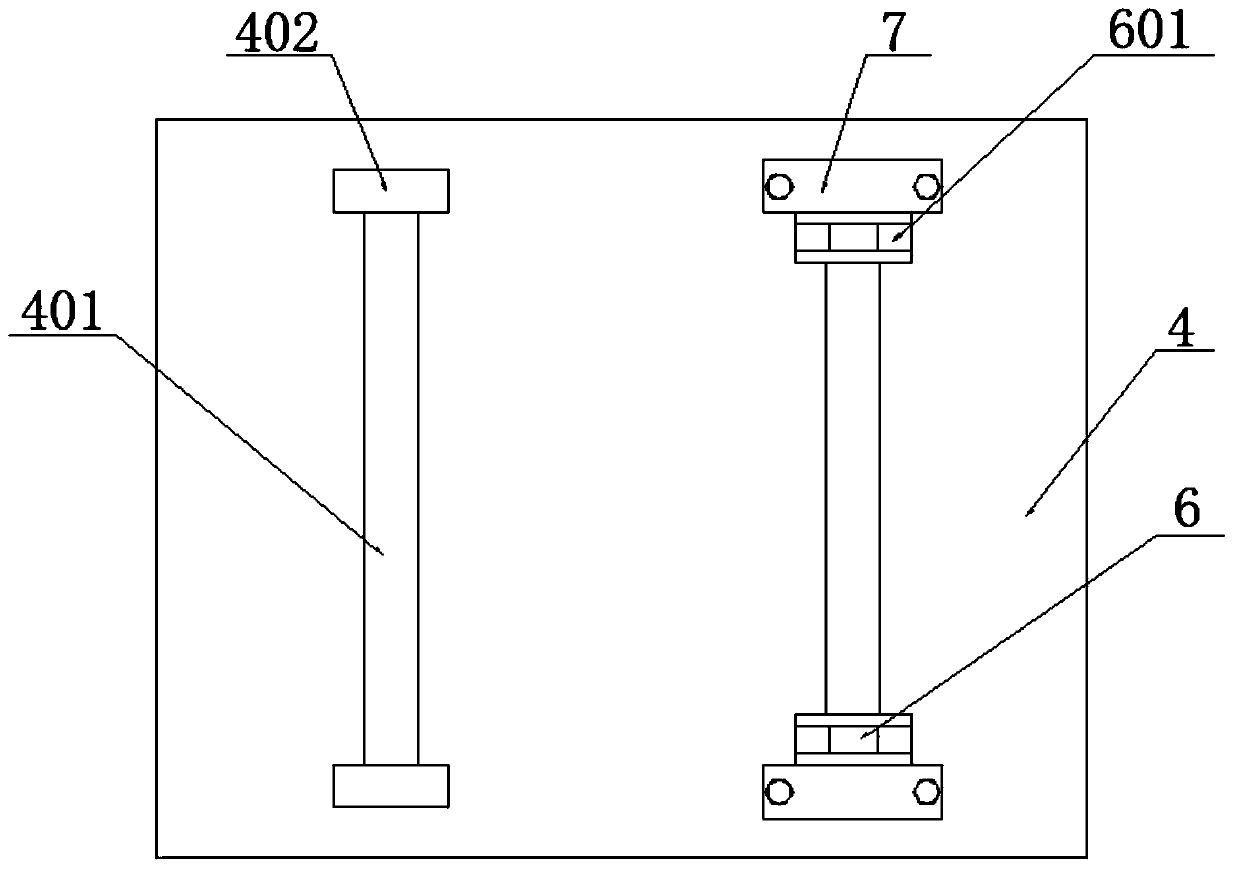

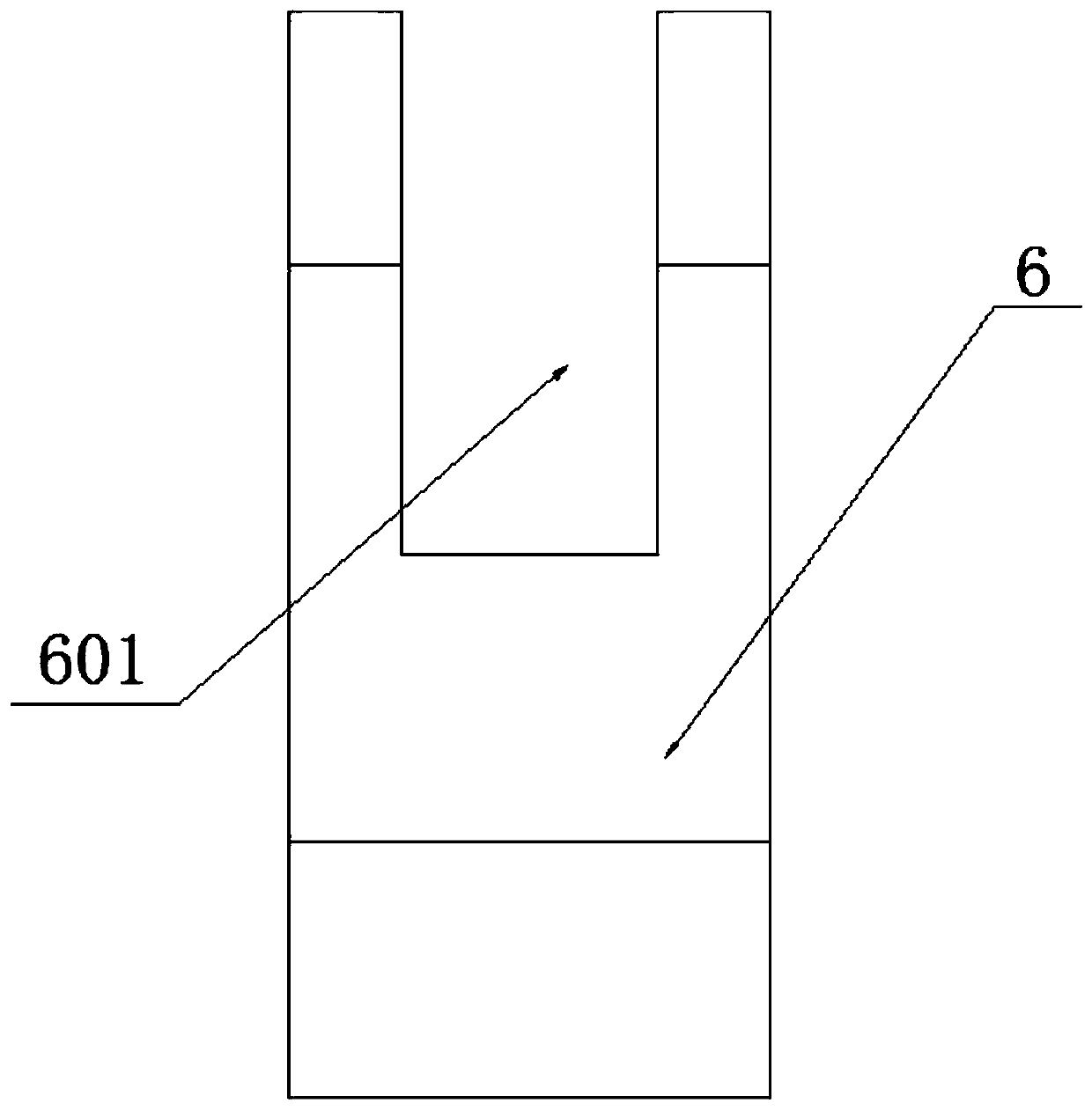

[0022] as attached figure 1 to attach image 3 Shown:

[0023] The present invention provides a clamper for auto parts, including a lifting platform main body 1, a trolley chassis 2, a trolley handle 3, a loading platform 4, a chute 401, a mounting groove 402, a connecting rod 5, and an I-shaped connector 6 , card slot 601, cover plate 7, splint 8 and connection hole 801; described lifting platform main body 1 is made of trolley chassis 2, trolley handle 3, manual hydraulic lifting mechanism and loading platform 4, and trolley chassis A pair of guide wheels and universal wheels are respectively arranged on the right side and left side of the bottom of 2, and a manual hydraulic lifting mechanism is arranged above the trolley chassis 2, and a load that can move up and down is installed on the trolley chassis 2 through the lifting mechanism. Platform 4; the trolley handle 3 is a U-shaped metal pipe structure, and the trolley handle 3 is welded on the upper left side of the trol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com