A foundation pit support repair structure and its construction method

A technology for foundation pit support and repair structure, which is applied in foundation structure engineering, foundation structure repair, excavation, etc., can solve the problem of pile body displacement inclination, loss of foundation pit support row pile support effect, foundation pit support row Pile repair work is not easy and other problems, to achieve the effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

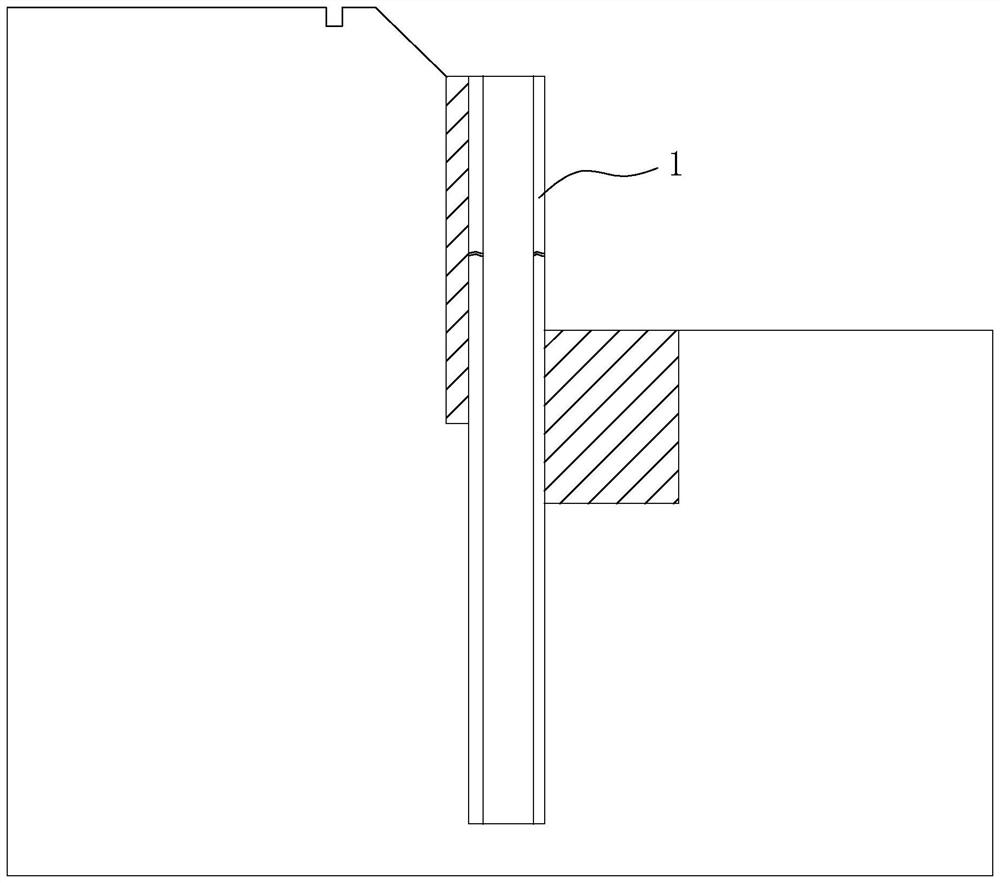

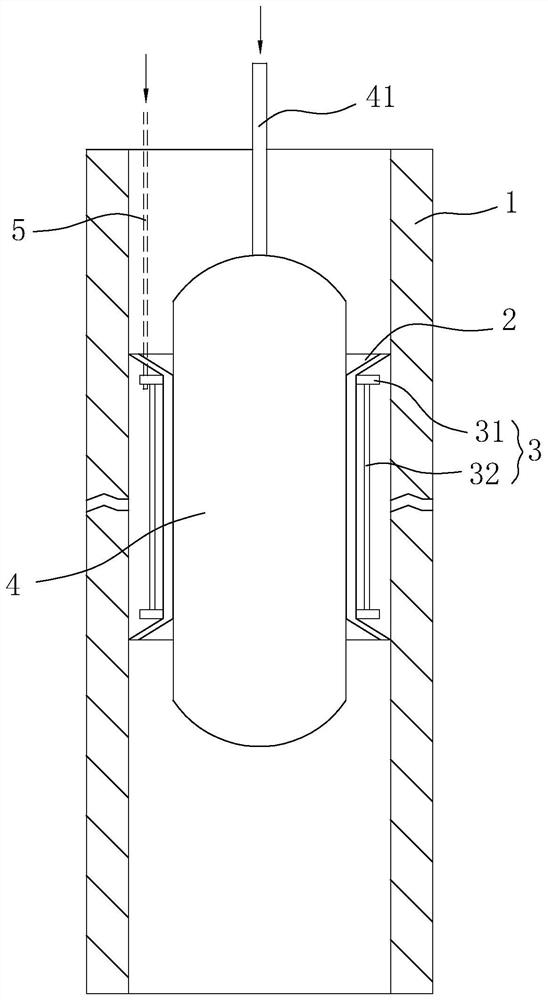

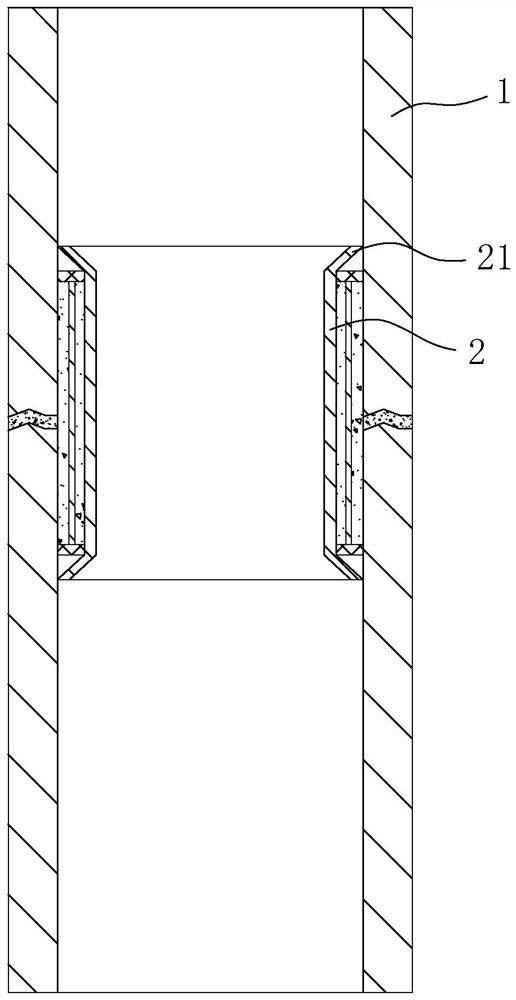

[0040] The foundation pit support repair structure includes a repair expansion ring 2 , a repair frame 3 , an air bag body 4 and a grouting pipe 5 .

[0041] Specifically, combined with figure 2 and Image 6 As shown, the repair expansion ring 2 is used to be inserted into the foundation pit support row pile 1. The repair expansion ring 2 is made of curled stainless steel sheets. The flange 21 has certain elasticity so that the anti-loosening flange 21 can be compressed. Wherein the repair expansion ring 2 has two coiled ends 22, the repair expansion ring 2 is expanded or retracted, the two coiled ends 22 of the repair expansion ring 2 can move relative to each other, and the two coiled ends 22 of the repair expansion ring 2 At least two one-way locking mechanisms 6 are arranged between the ends 22. After the expansion ring 2 is expanded, the one-way locking mechanisms 6 are used to limit the retraction of the two rolled ends 22 of the expansion ring 2. Wherein, the outer ...

Embodiment 2

[0054] A construction method for applying the foundation pit support repair structure described in the above technical scheme, comprising the steps of:

[0055] S1, excavating the soil body in the foundation pit support row pile 1 to the position of the foundation pit support row pile 1 crack;

[0056] S2, install the repair frame 3 outside the repair expansion ring 2, put the repair expansion ring 2 into the pile row 1 of the foundation pit support, so as to align the cracks of the pile row 1 of the foundation pit support with the repair frame 3;

[0057] S3, put the airbag body 4 into the repair expansion ring 2 and inflate it, the expansion of the air bag body 4 drives the inner diameter of the repair expansion ring 2 to expand, so that the repair frame 3 is closely attached to the inner wall of the foundation pit support row pile 1 and surrounds the foundation Remove the airbag body 4 for the crack of the pit support row pile 1;

[0058] S4, through the grouting pipe 5, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com