A cold-formed thin-walled steel plate wall system with built-in friction and negative stiffness composite damping device

A cold-formed thin-wall, vibration-damping device technology, applied to walls, buildings, building types, etc., can solve problems such as inability to arrange vibration-damping devices, save workload, reduce structural natural vibration frequency, and transmit vibration. The effect of saving working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The specific embodiments of the present invention will be described in detail below with reference to the drawings.

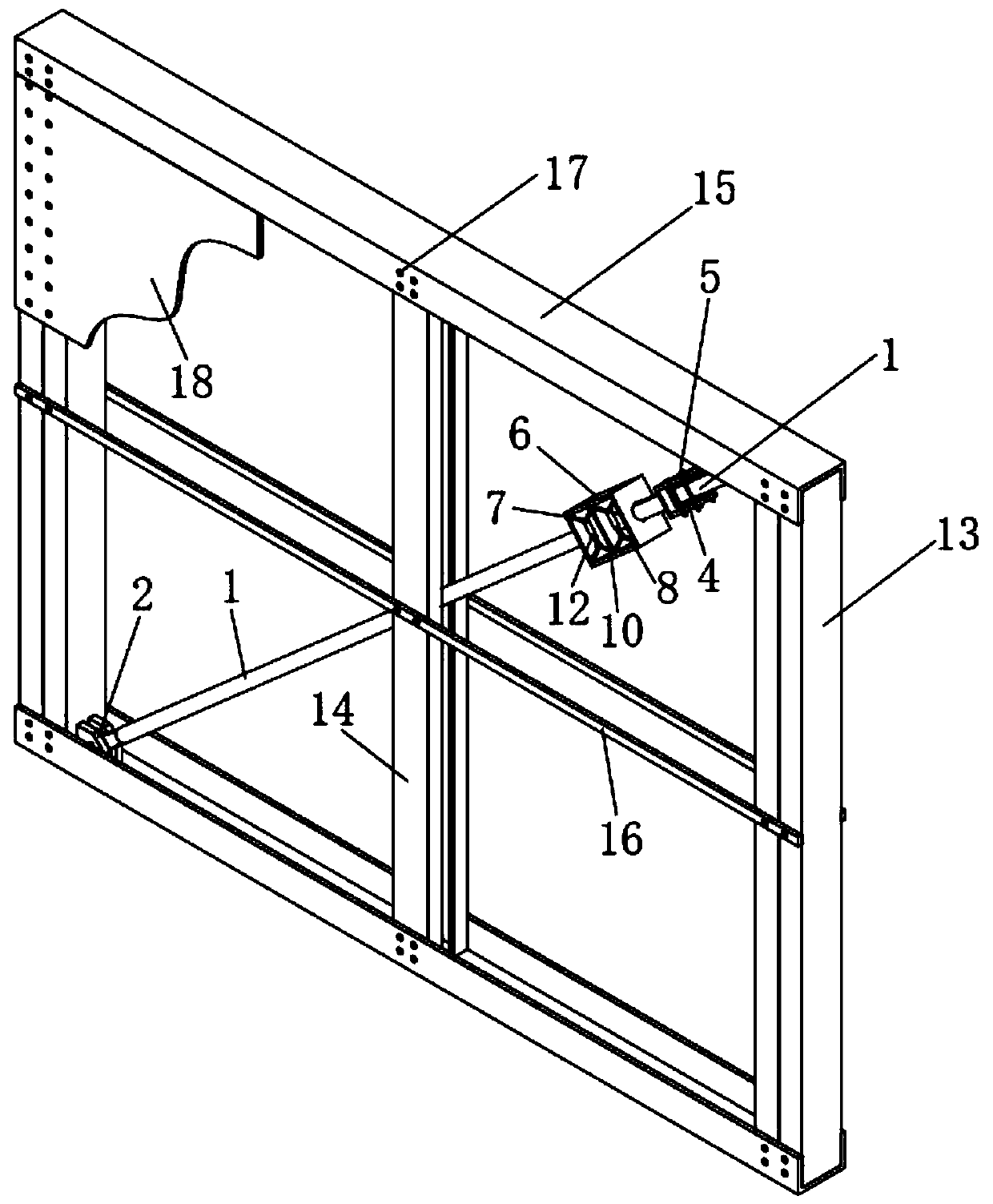

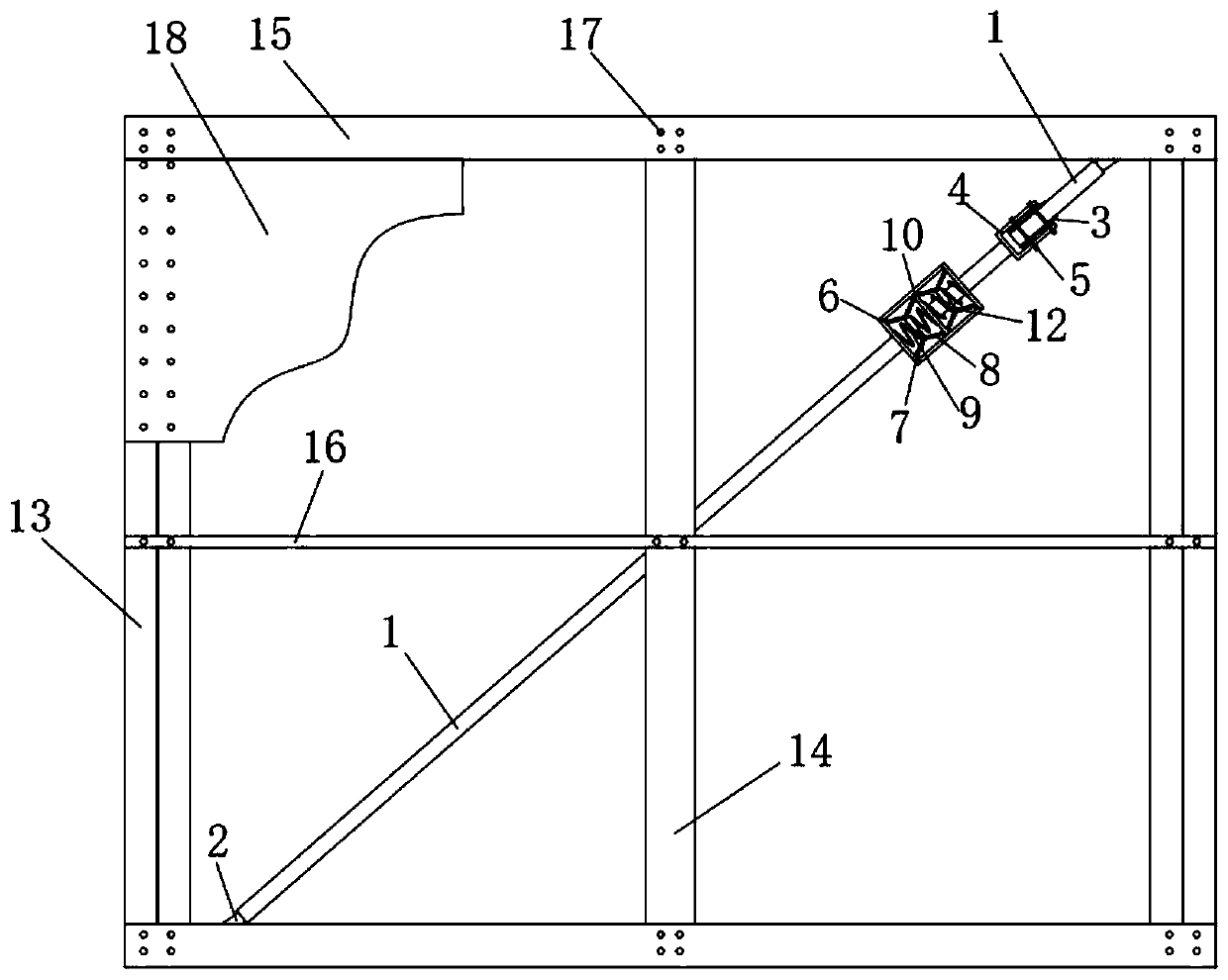

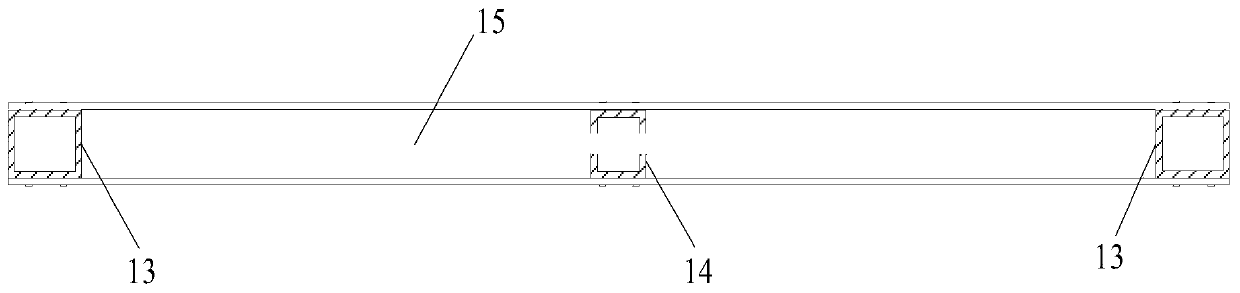

[0043] Such as figure 1 Shown is an embodiment of a cold-formed thin-walled steel plate wall system with a built-in friction and negative stiffness composite vibration reduction device of the present invention, which mainly includes: metal support square rod 1, hinge support 2, friction plate 3, groove Type metal plate 4, bolt 5, metal box 6, universal hinge 7, inclined rod 8, metal spring 9, high-strength metal plate 10, tension spring group 11, metal sleeve 12, side column 13, column 14, and rail beam 15. Steel belt horizontal brace 16, screws 17, wall panel 18.

[0044] The specific implementation steps are as follows:

[0045] 1) Vibration reduction design for a cold-formed thin-wall steel plate wall. The wall keel is composed of side columns, columns, top rail beams, and bottom rail beams. The joints are connected by bolts. The cross-section forms of si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com