Accurate proppant placement method for hydraulic fracturing of multi-interlayer oil-gas reservoir

A hydraulic fracturing and proppant technology, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc. It can solve the problems that the proppant cannot be delivered to the target layer, cannot meet the design requirements, and the effect of oil and gas reservoir stimulation is poor, etc. problems, to achieve the effect of improving laying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] Each step of the present invention will be described in detail below through specific examples.

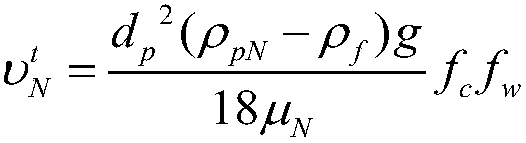

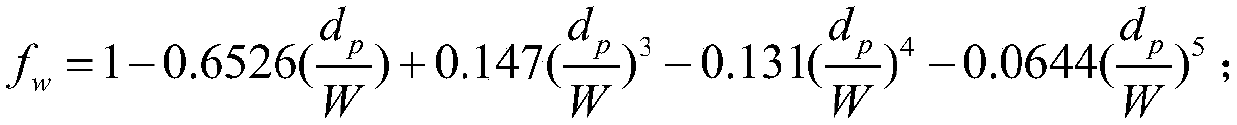

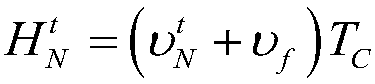

[0083] Taking a single well W in an oilfield as an example, the hydraulic fracturing section is designed to have a burial depth of 4309.4-4323m and contains many interlayers. The average formation temperature of this section is 140°C, and the formation fracture closure pressure is 48MPa. According to previous numerical software simulation results, the density of fracturing fluid is 1200kg / m 3 , the apparent viscosity of the pad fluid is 0.04Pa·s, the particle diameter of the proppant is 0.0006m, and the sand ratio is 20% (that is, the volume fraction of liquid in the mixture of proppant and fracturing fluid is 86%). After the pump is stopped, the fracture closes The time is 3000s, and the vertical downward migration speed of the sand-carrying fluid in the fracture is 0.002m / s. Under this condition, fractures with an average width of 0.004m are created. Based on this, the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com