Pipeline multi-point leakage accurate positioning method

A precise positioning and pipeline technology, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve problems such as signal non-stationarity, affecting diagnosis results, source signal aliasing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

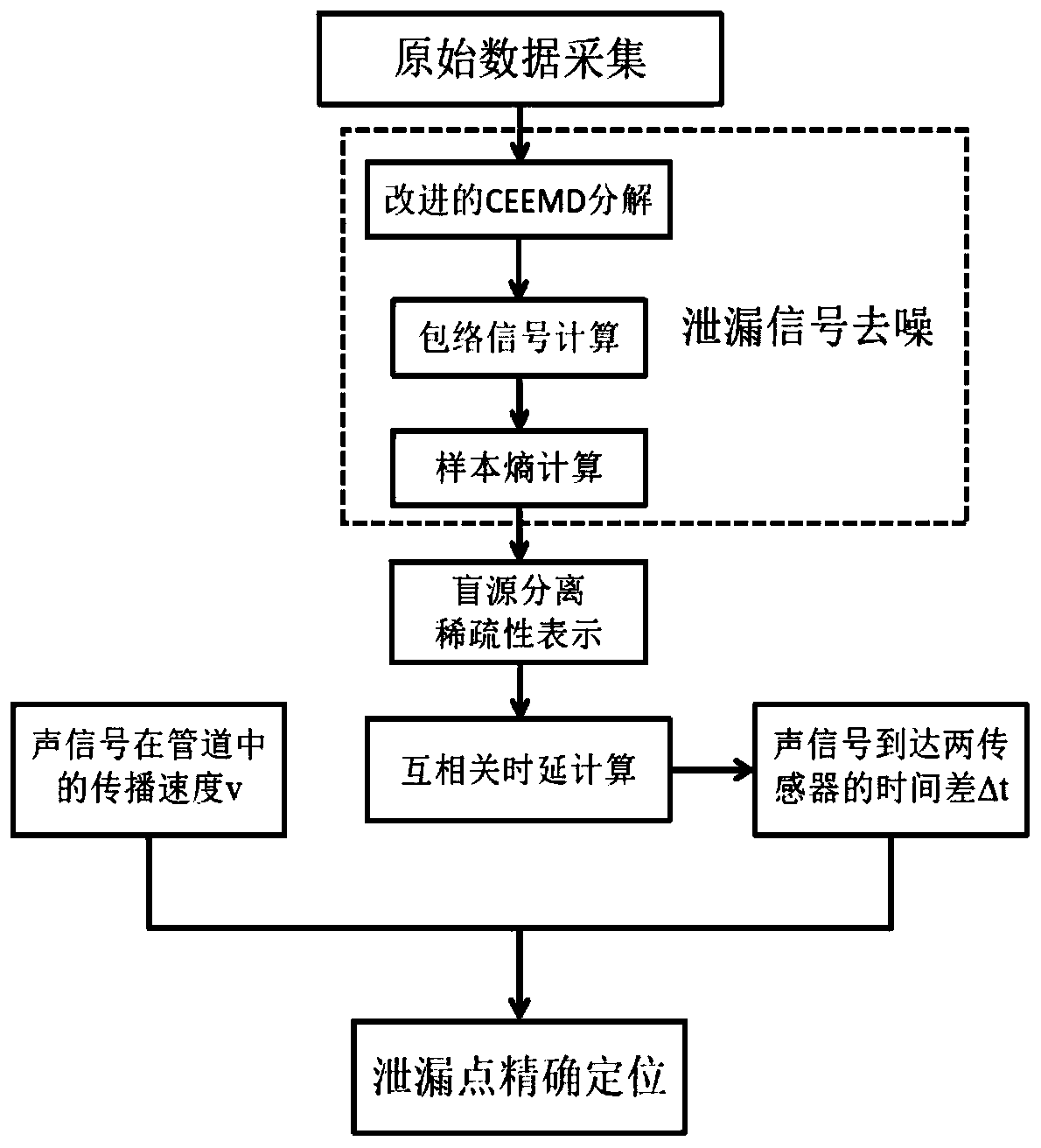

[0089] Such as figure 1 As shown, a method for accurately locating pipeline multi-point leaks of the present invention comprises the following steps:

[0090] S1: Install an acoustic emission sensor at both ends of the pipeline under test, and the distance between the two acoustic emission sensors is L, and use the acoustic emission sensors at both ends to collect the original leakage signal x(t);

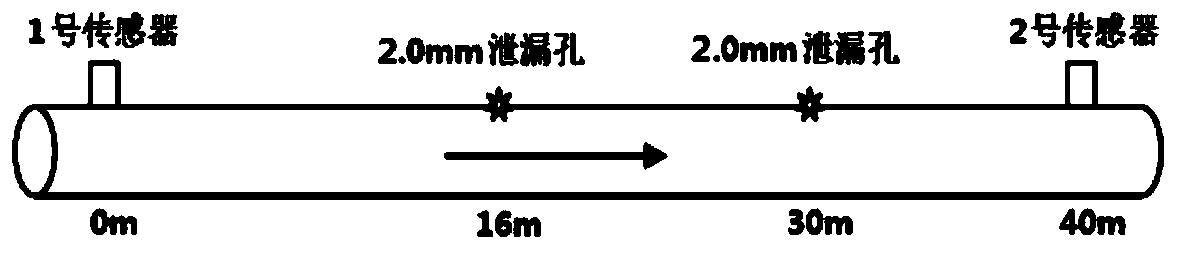

[0091] Experimental pipelines such as figure 2 , the pipeline length is 50m, the pipeline material is steel, the pipeline specification is DN150, the medium is compressed air, and the medium in the pipeline is in a flowing state; the upstream acoustic emission sensor 1 is placed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com