Sealing mechanism for high-pressure detection of TMC master cylinder

A technology of high-pressure detection and sealing mechanism, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, etc., which can solve the problems of high device cost and inability to solve the problem of good sealing of TMC main cylinder, etc., and achieve the effect of effective sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

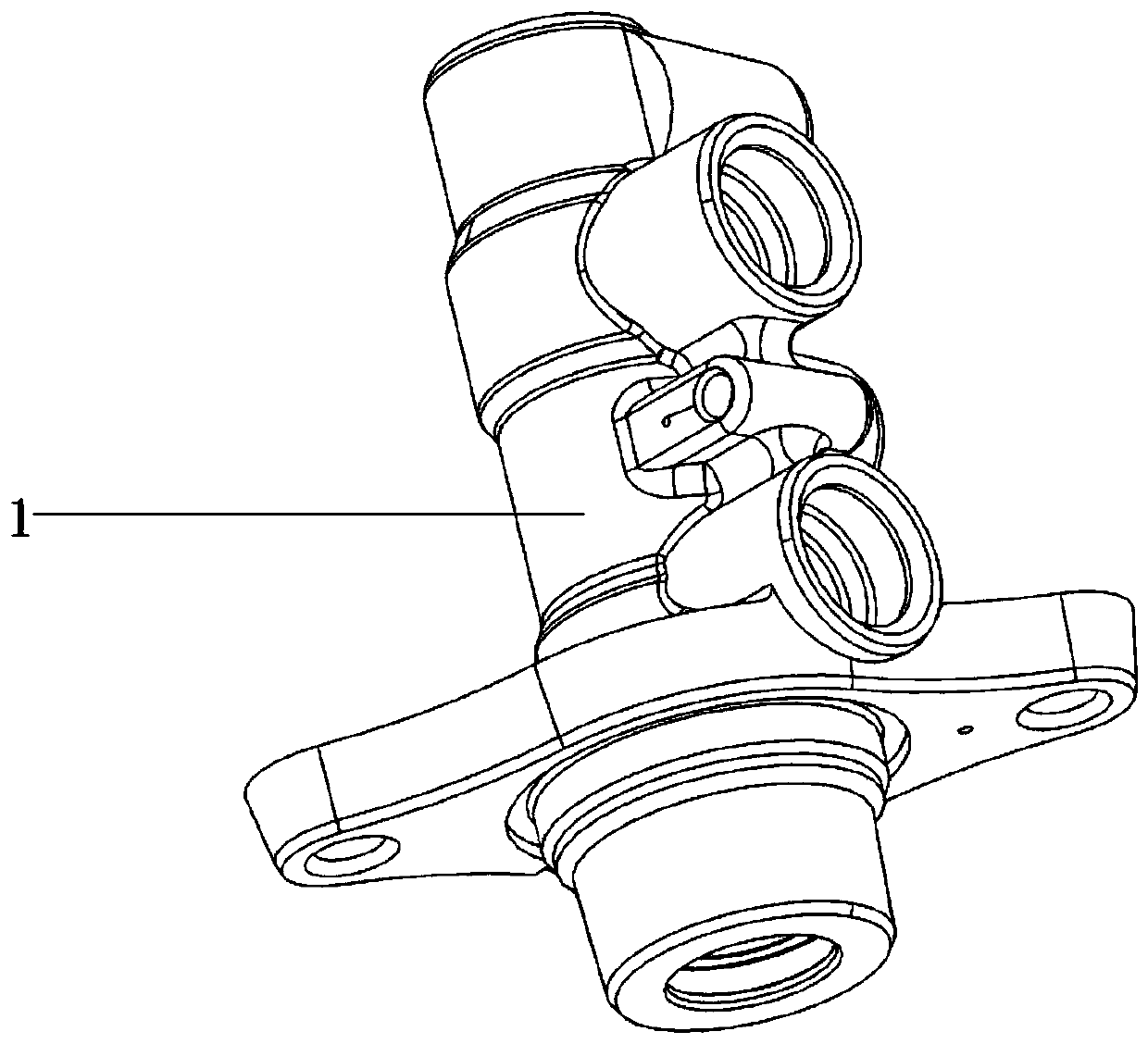

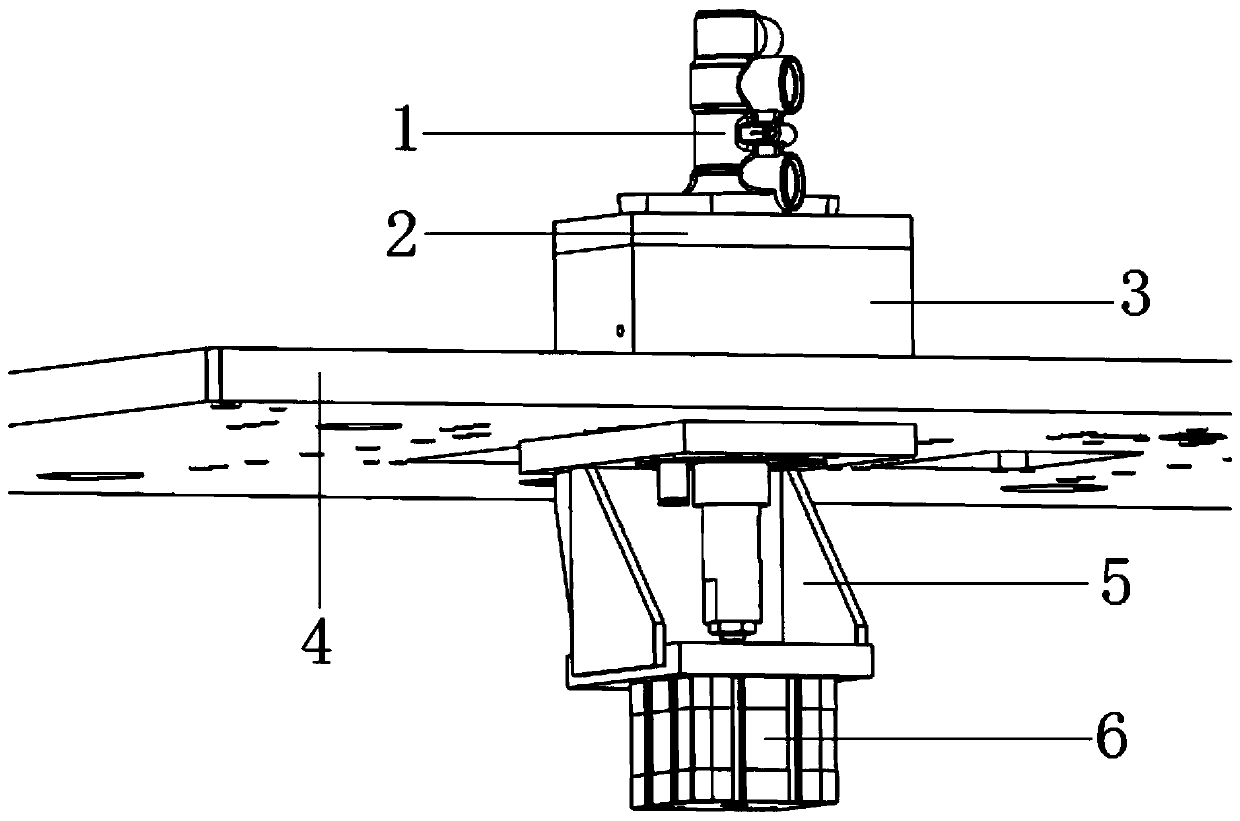

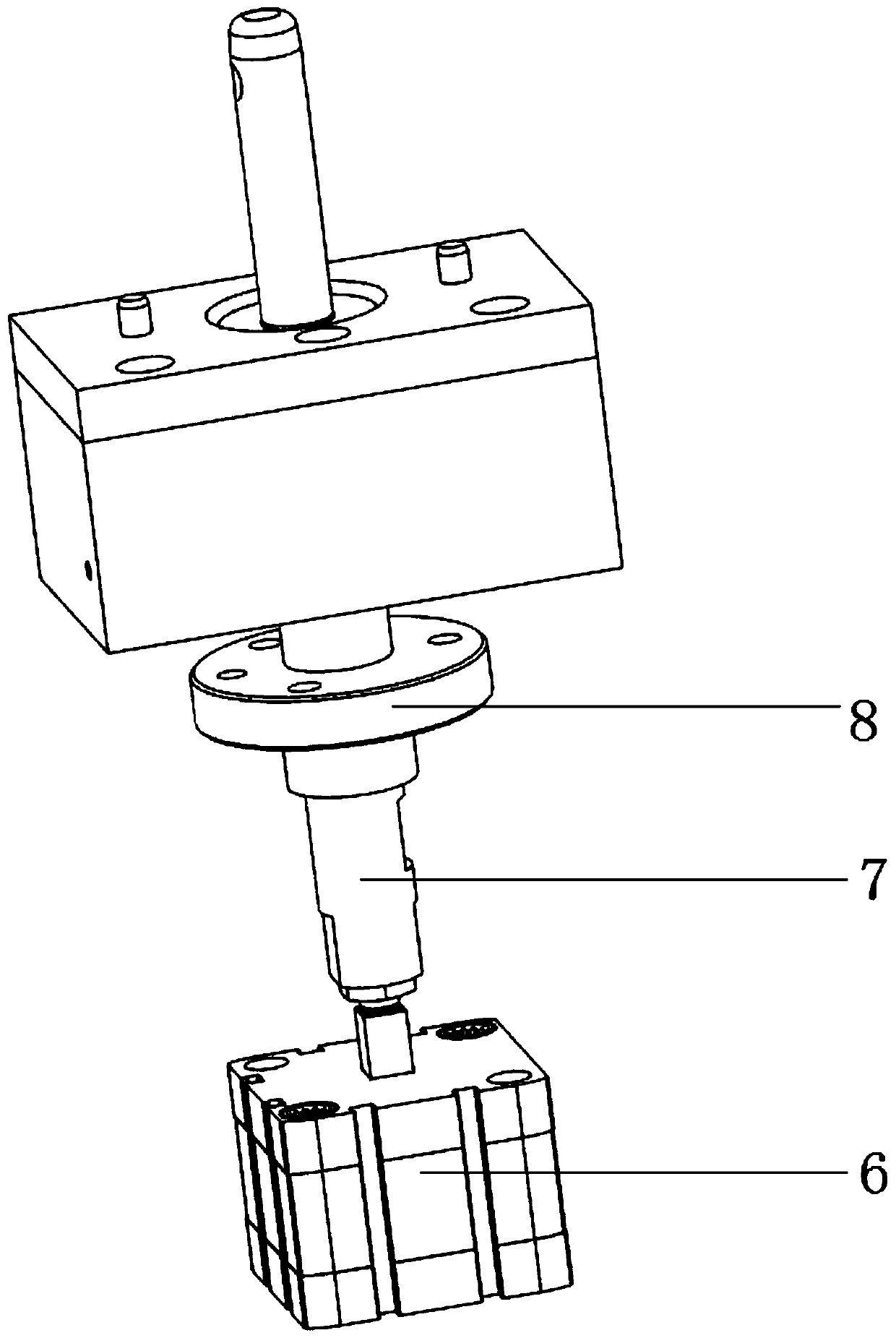

[0040] figure 1 It is the TMC master cylinder to be detected in the present invention. Such as Figure 2-7 , the present invention provides a sealing mechanism for TMC master cylinder high pressure detection, including a reference table 4, also includes a sealing ventilation unit, the sealing ventilation unit includes a ventilation rod 7, a positioning sliding sleeve 8, a limit sleeve 9, a seal 10 and The ventilation pressure head 11, the positioning sliding sleeve 8, the limit sleeve 9 and the seal 10 are sequentially set on the ventilation rod 7 from bottom to top, the ventilation pressure head 11 is fixed on the upper end of the ventilation rod 7, and the top of the reference table 4 is set There is a positioning component for fixing and supporting the TMC master cylinder 1. The positioning sliding sleeve 8 is fixedly installed on the lower end of the reference table 4. The lower end of the ventilation rod 7 is connected to the driving mechanism. Under the action of the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com