Blade structure detection method and system based on machine vision, medium and equipment

A technology of machine vision and blade structure, applied in the direction of instrumentation, image data processing, calculation, etc., can solve the problems of inability to obtain blade structure data, low accuracy rate, and low efficiency of blade structure detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

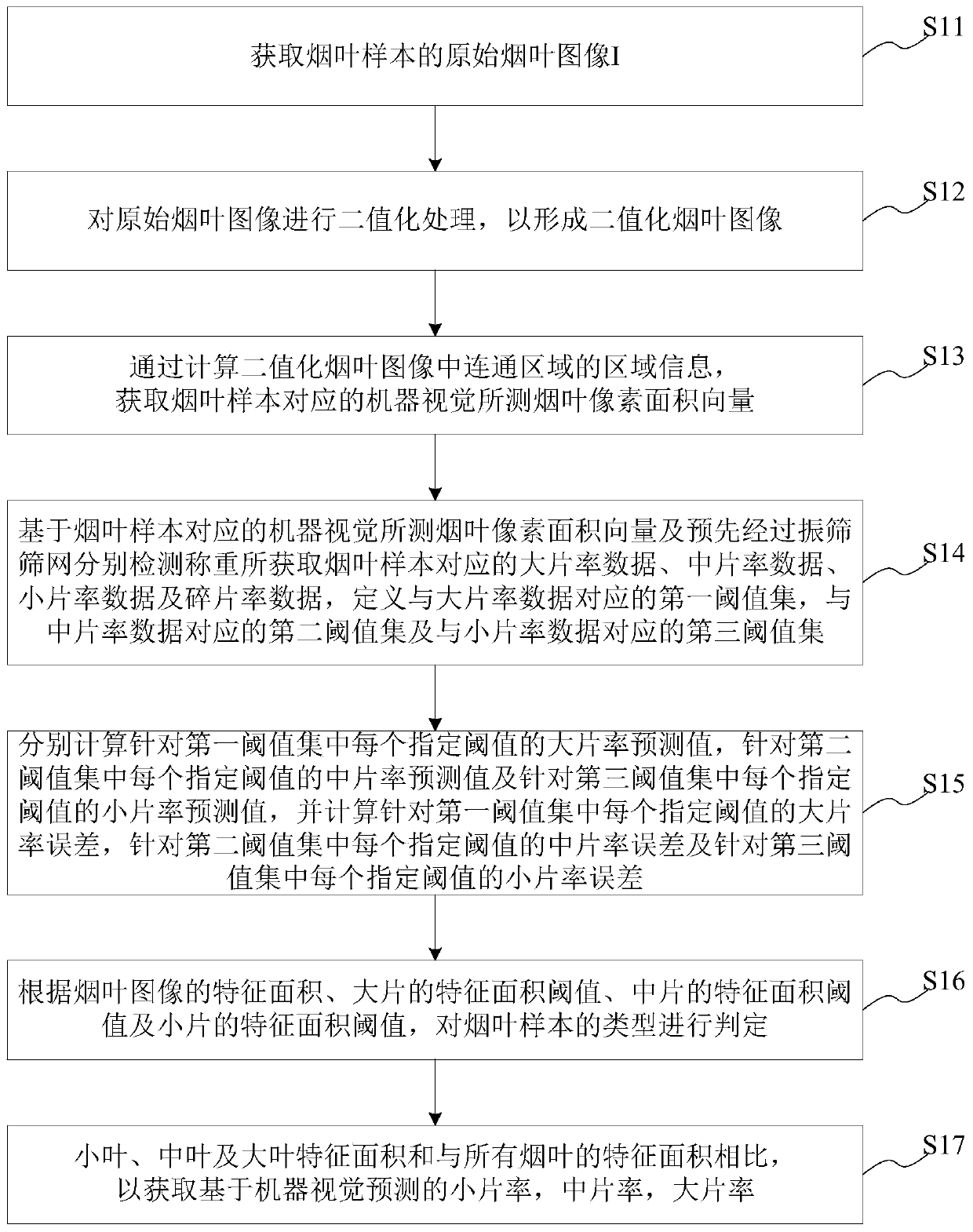

[0047] This embodiment provides a blade structure detection method based on machine vision, including:

[0048] Obtain the original tobacco leaf image of the tobacco leaf sample;

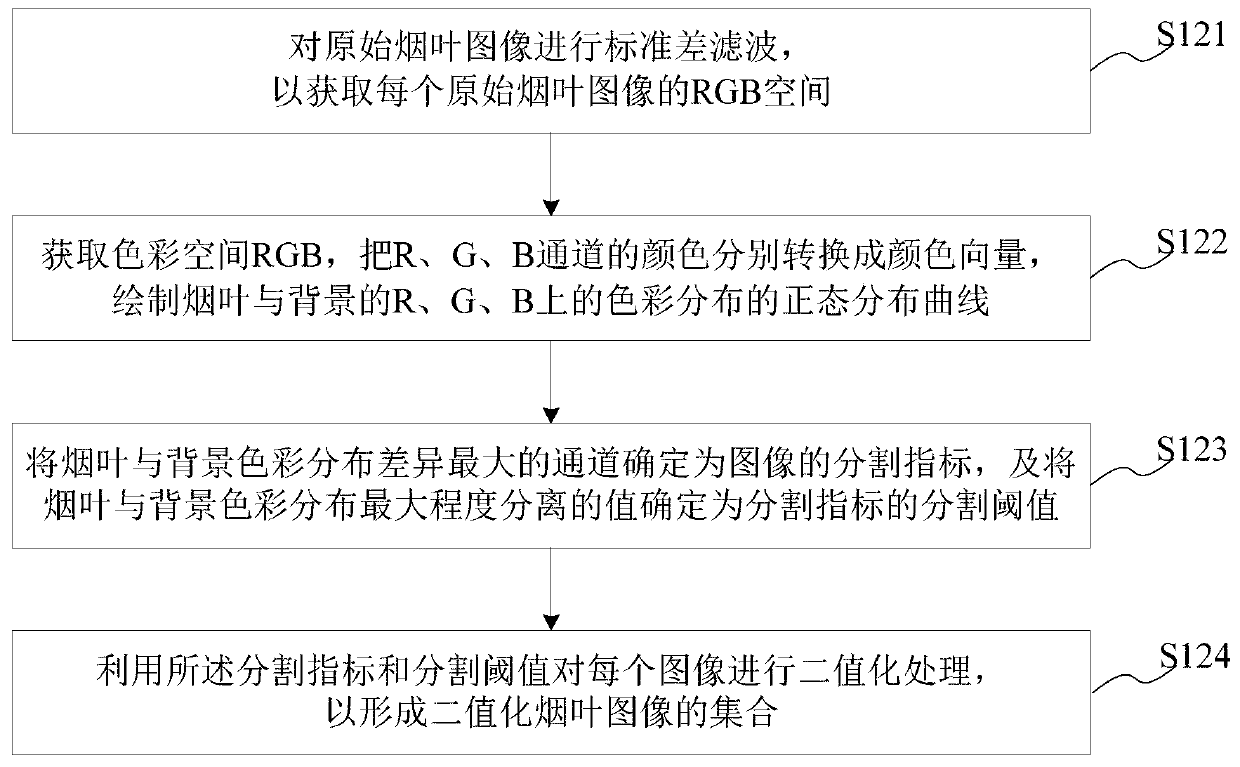

[0049] performing binarization processing on the original tobacco leaf image to form a binarized tobacco leaf image;

[0050] By calculating the area information of the connected area in the binarized tobacco leaf image, the tobacco leaf pixel area vector corresponding to the machine vision measurement of the tobacco leaf sample is obtained;

[0051] Based on the tobacco leaf pixel area vector measured by the machine vision corresponding to the tobacco leaf sample and the large piece rate data, medium piece rate data and small piece rate data corresponding to the tobacco leaf samples obtained by the vibrating sieve screen respectively detected and weighed in advance, the definition and the described large piece rate data A corresponding first threshold set, a second threshold set corresponding to t...

Embodiment 2

[0119] This embodiment provides a blade structure detection system based on machine vision, including:

[0120] The first acquisition module is used to acquire the original tobacco leaf image of the tobacco leaf sample;

[0121] A binarization processing module, configured to perform binarization processing on the original tobacco leaf image to form a binarized tobacco leaf image;

[0122] The second acquisition module is used to obtain the tobacco leaf pixel area vector measured by machine vision corresponding to the tobacco leaf sample by calculating the area information of the connected area in the binarized tobacco leaf image;

[0123] The threshold set definition module is used to measure the tobacco leaf pixel area vector based on the machine vision corresponding to the tobacco leaf sample and the large slice rate data, medium slice rate data and small slice rate data corresponding to the tobacco leaf samples obtained by the vibrating sieve screen respectively detected a...

Embodiment 3

[0151] This embodiment provides a device, the device includes: a processor, a memory, a transceiver, a communication interface or / and a system bus; the memory and the communication interface are connected to the processor and the transceiver through the system bus and complete mutual communication, The memory is used to store computer programs, the communication interface is used to communicate with other devices, and the processor and transceiver are used to run the computer programs, so that the devices can execute the steps of the blade structure detection method based on machine vision.

[0152] The system bus mentioned above may be a Peripheral Component Interconnect (PCI for short) bus or an Extended Industry Standard Architecture (EISA for short) bus or the like. The system bus can be divided into address bus, data bus, control bus and so on. The communication interface is used to realize the communication between the database access device and other devices (such as cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com