Camera calibration board, calibration method and camera

A camera calibration and camera technology, applied in image analysis, image data processing, instruments, etc., can solve problems such as poor robustness, inability to adapt to shortcomings or noise, achieve flexible placement, and improve robustness and accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

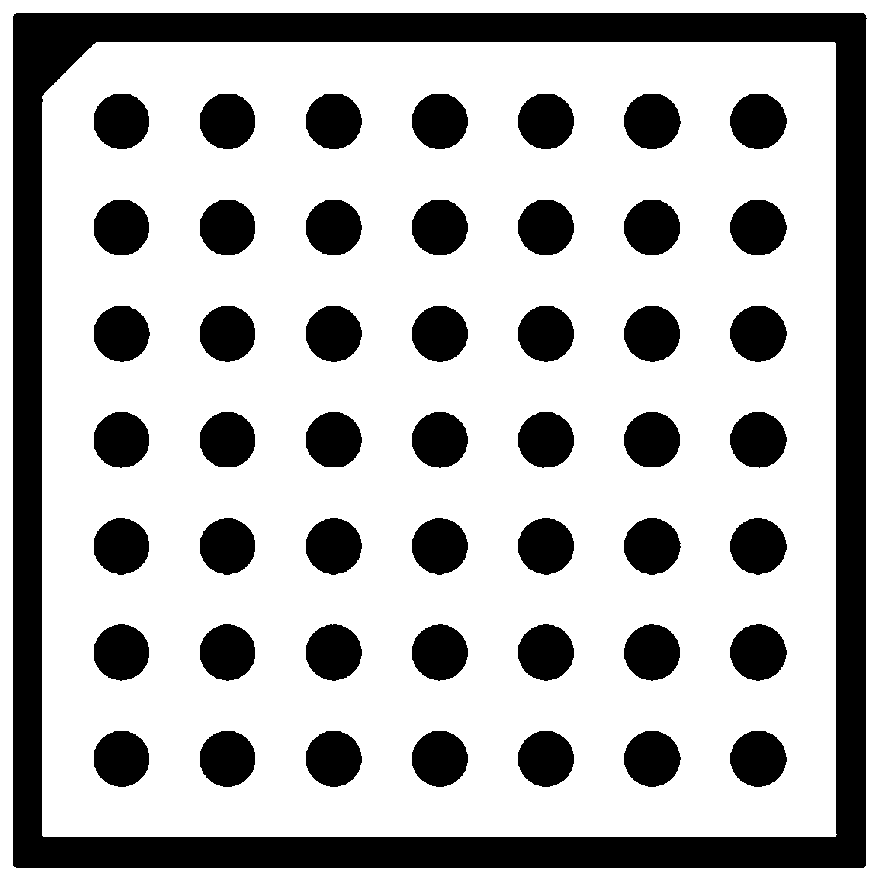

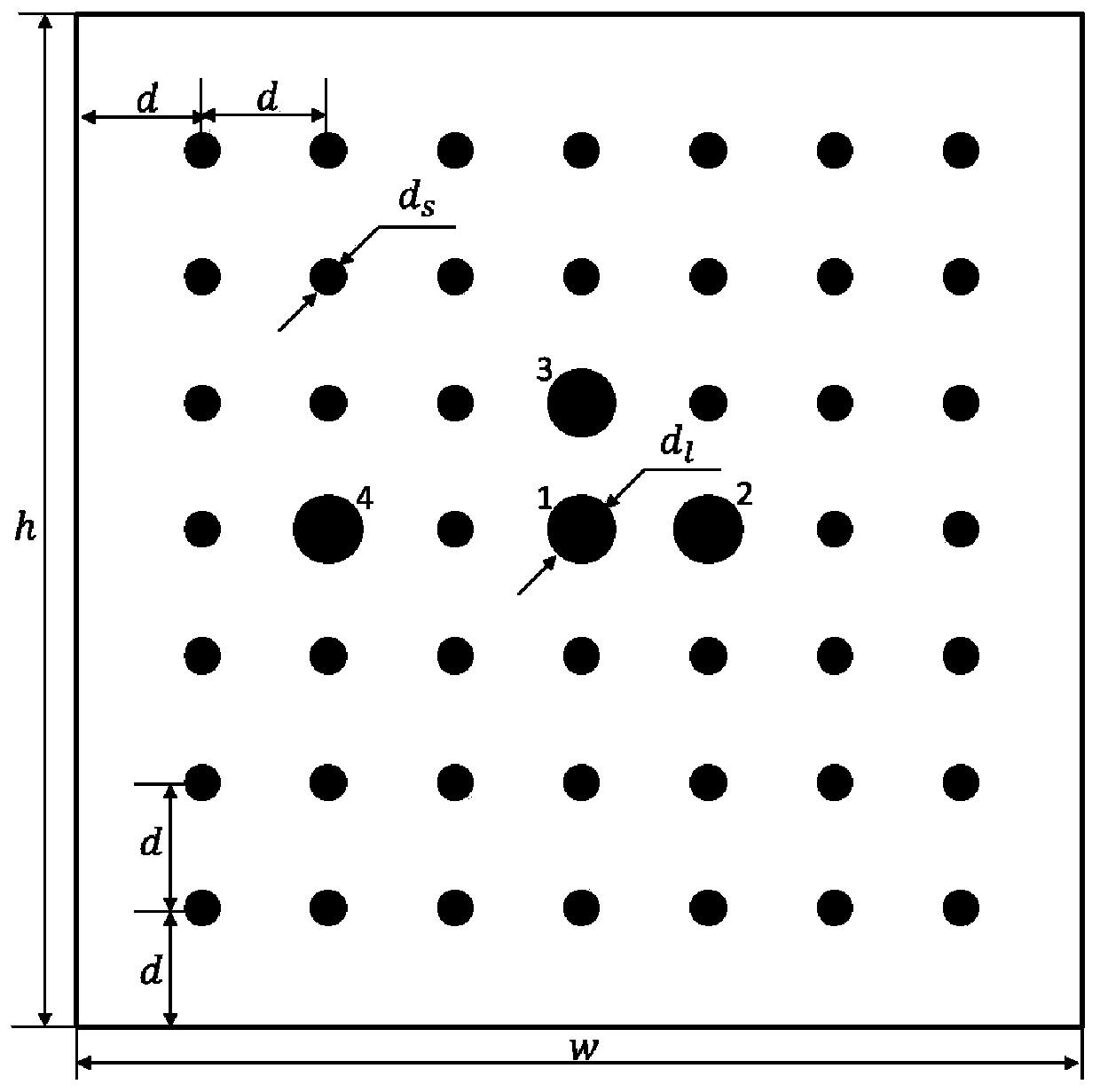

[0043] Such as image 3 As shown, the camera calibration plate provided in this embodiment includes a plurality of dots, where the dots are solid dots, that is, the dots are filled with color, for example, the dots are filled with black. The dots are divided into datum dots and reference dots; as an option, the datum dots in this embodiment are larger than the reference dots, that is, the diameter of the datum dots is larger than the diameter of the reference dots. The reference dots and reference dots are arranged in a checkerboard shape, all rows are parallel, all columns are parallel, all rows and all columns are perpendicular to each other; the distance between adjacent dots in each row is equal, and the distance between adjacent dots in each column is equal. The dots are equally spaced, and the distance between adjacent dots in each row is equal to the distance between adjacent dots in each column. The distance between adjacent rows mentioned here refers to the distance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com