Permanent magnet synchronous motor maximum efficiency torque ratio control method and permanent magnet synchronous motor maximum efficiency torque ratio controller

A technology of permanent magnet synchronous motor and maximum efficiency, which is applied in the direction of motor generator control, electromechanical brake control, electronic commutation motor control, etc. Slow and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments.

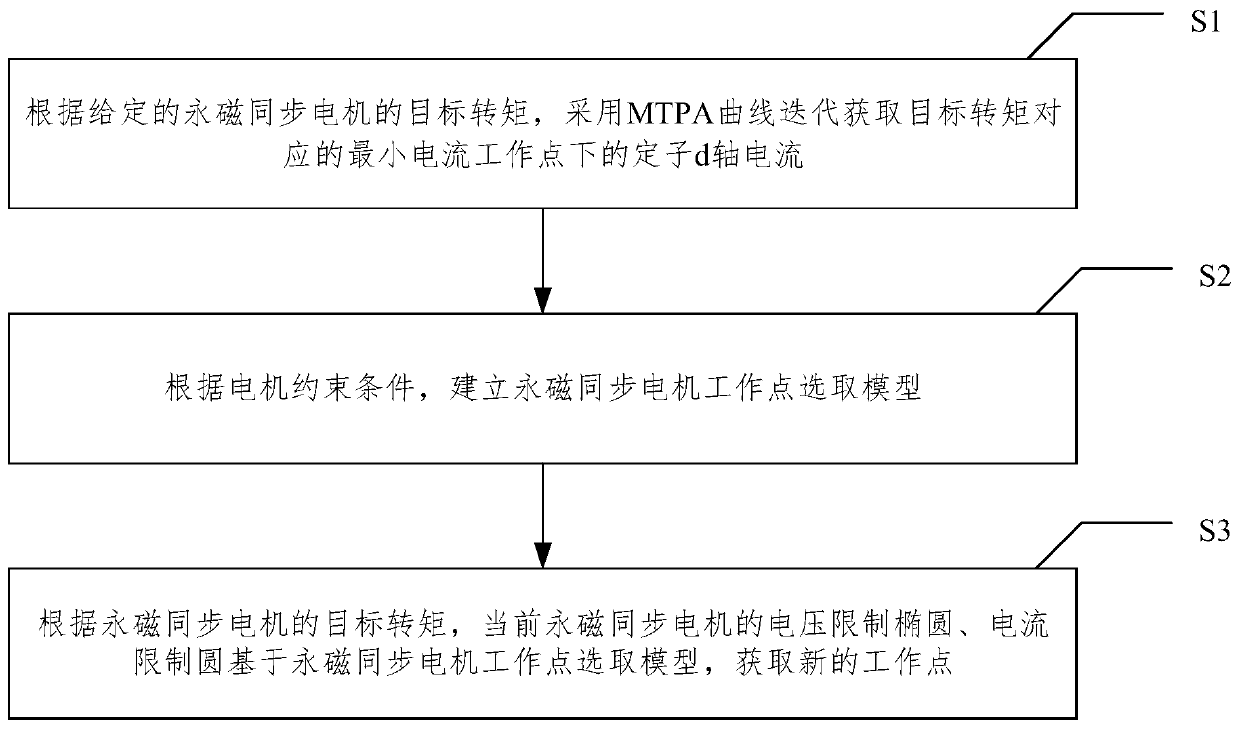

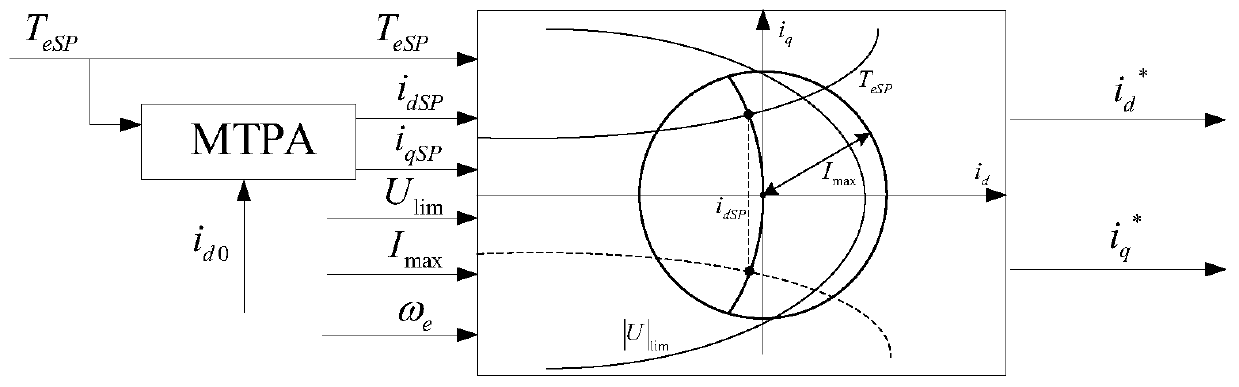

[0084] The maximum efficiency torque ratio control structure diagram of the present invention is as follows figure 2 shown. Its basic control rules are as follows:

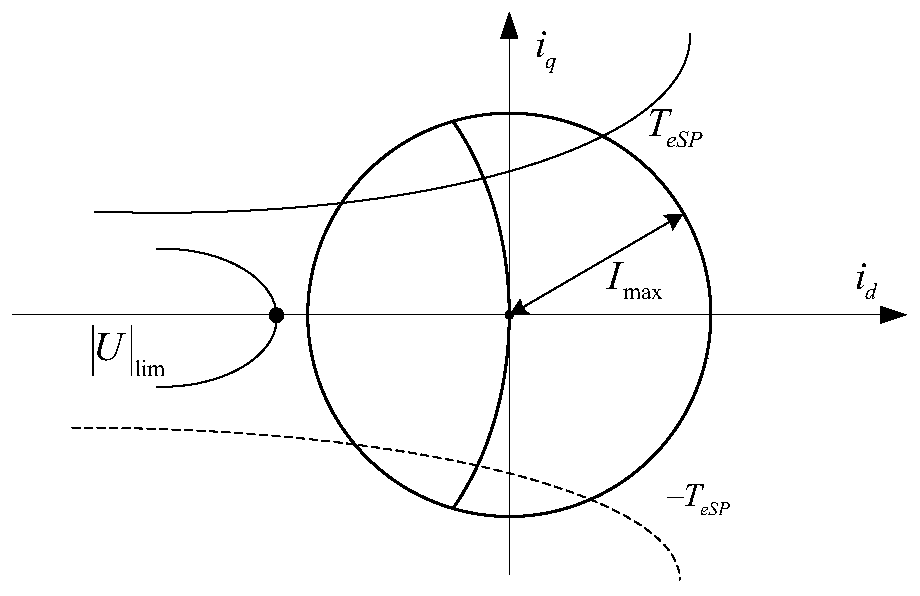

[0085] (1) Select the current set {(i d ,i q )}, under the premise of satisfying the constraints, the actual torque T e As close as possible to the target torque T eSP ,which is:

[0086] {(i d ,i q )}=argmin|T eSP -T e | (1)

[0087] and satisfy the constraints:

[0088]

[0089] Among them: |U|, |I|-stator voltage and current single-phase amplitude; u d , u q - stator d-axis voltage and q-axis voltage; i d , i q -Stator d-axis current and q-axis current; where the 3 / 2 transformation adopts the amplitude-invariant constraint.

[0090] (2) In the collection {(i d ,i q )} to select the combination closest to the MTPA curve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com