Method for the automated calibration of a printing machine

A technology for printing machines and printing samples, applied in the directions of printing, printing devices, transfer materials, etc., can solve problems such as not being favorable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

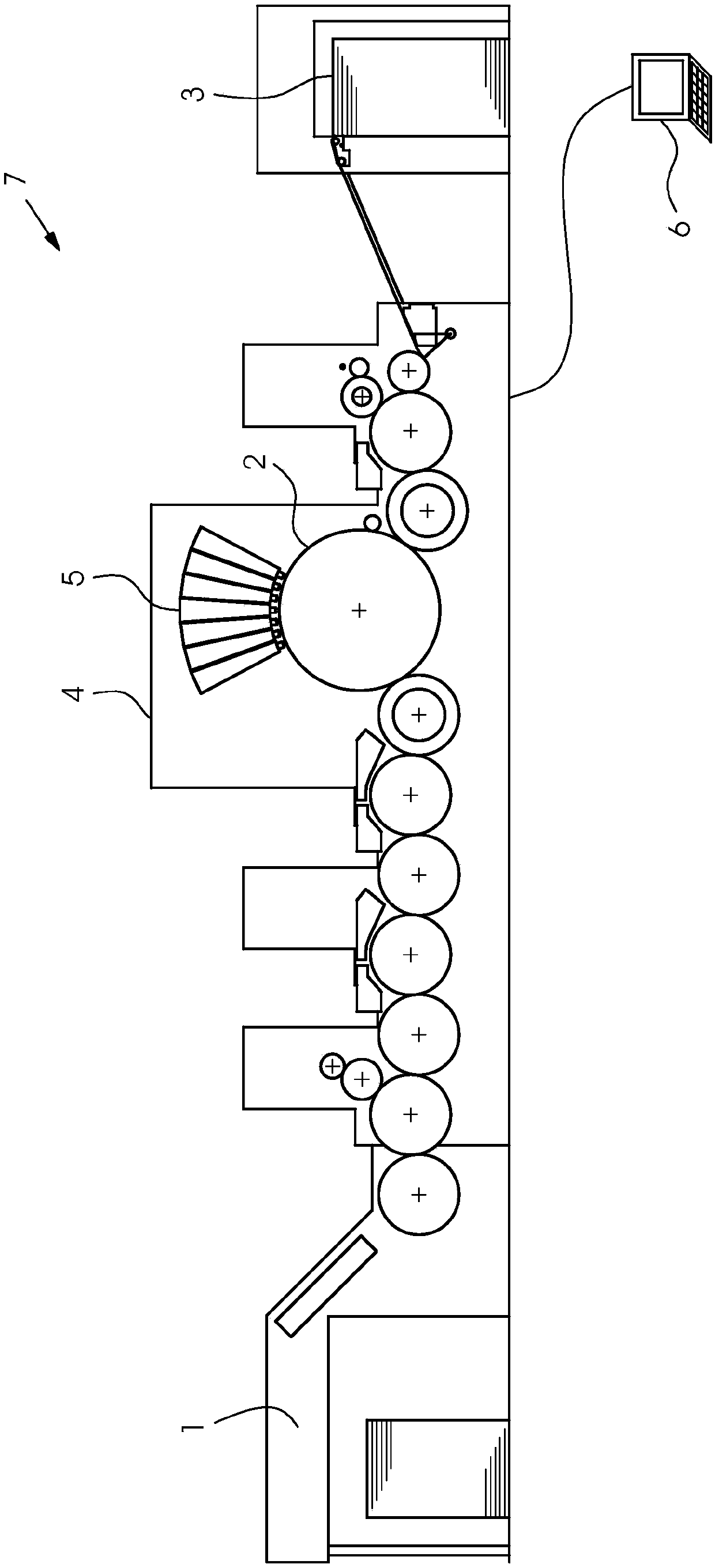

[0023] The field of application of a preferred embodiment variant of the method according to the invention is inkjet printers 7 . exist figure 1 An example of the basic structure for such a machine 7 is shown in , comprising the feeder 1 up to the receiver 3 for feeding the printing substrate 2 into the printing unit 4 in which the substrate is printed by the printing head 5 Substrate 2 is printed. This is a sheet inkjet printing press 7 , which is controlled by a control computer 6 .

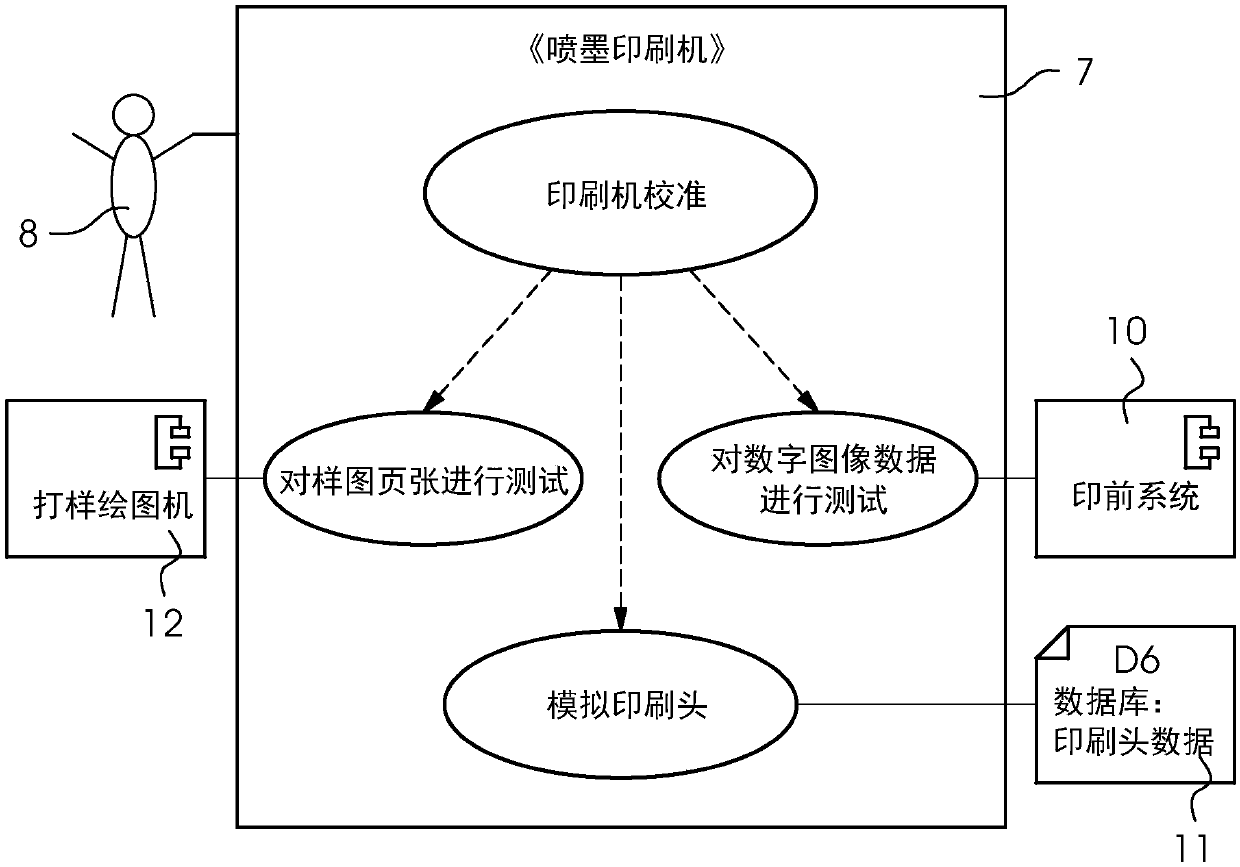

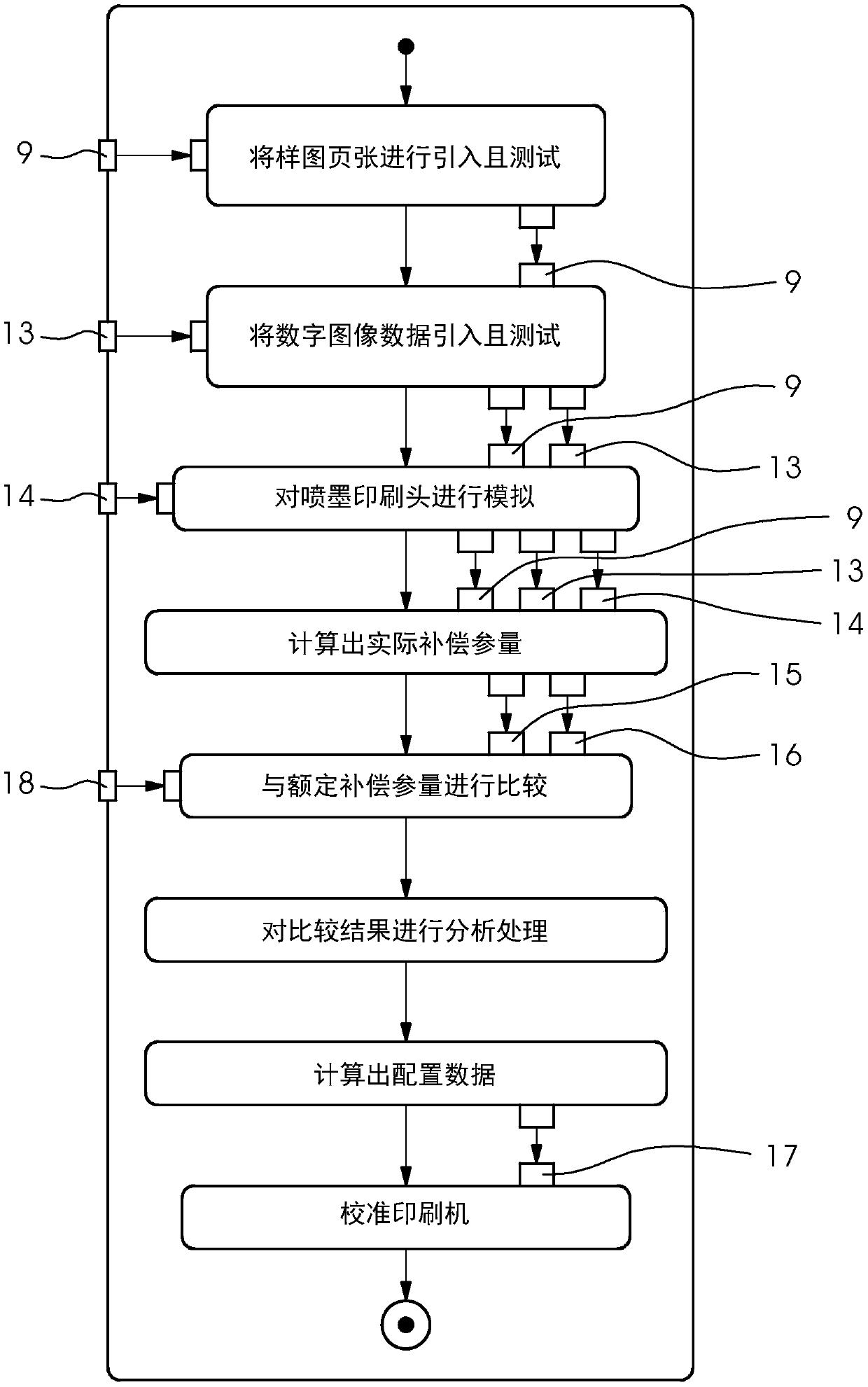

[0024] When (or after) such an inkjet sheet printing machine 7 is assembled, a complete functional test at this point (including eliminating any errors found by means of calibrating the newly constructed sheet inkjet printing press 7) is worth looking forward to. This application scenario is in the preferred implementation variant in figure 2 in public. Because this cannot be carried out by (as in an offset printing press) real proof printing, so this occurs as follows: its mode is that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com