Engraving machine

A technology of engraving machine and frame, which is applied in the field of engraving machines, can solve the problems of inconvenient maintenance and cleaning, and achieve good dust-proof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

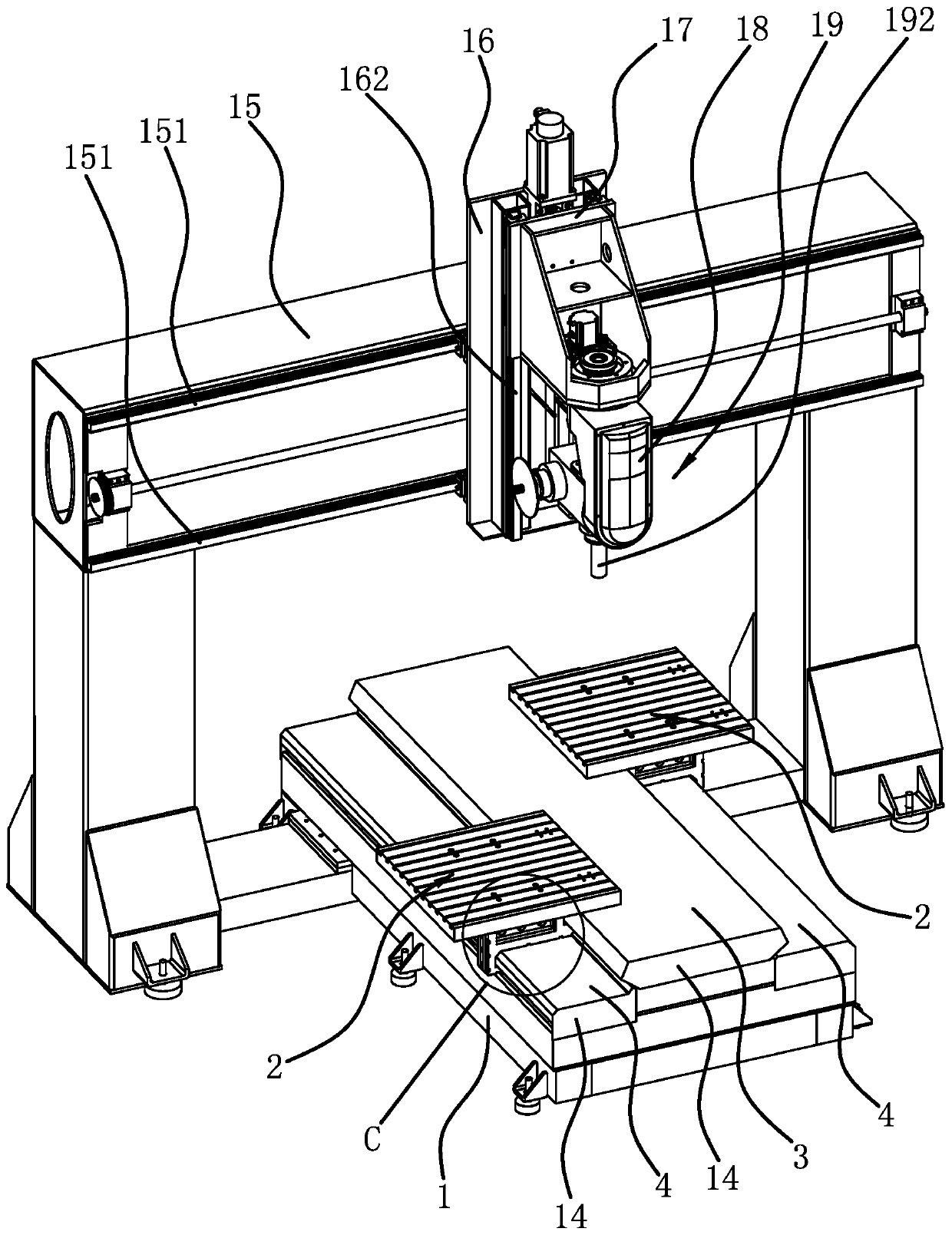

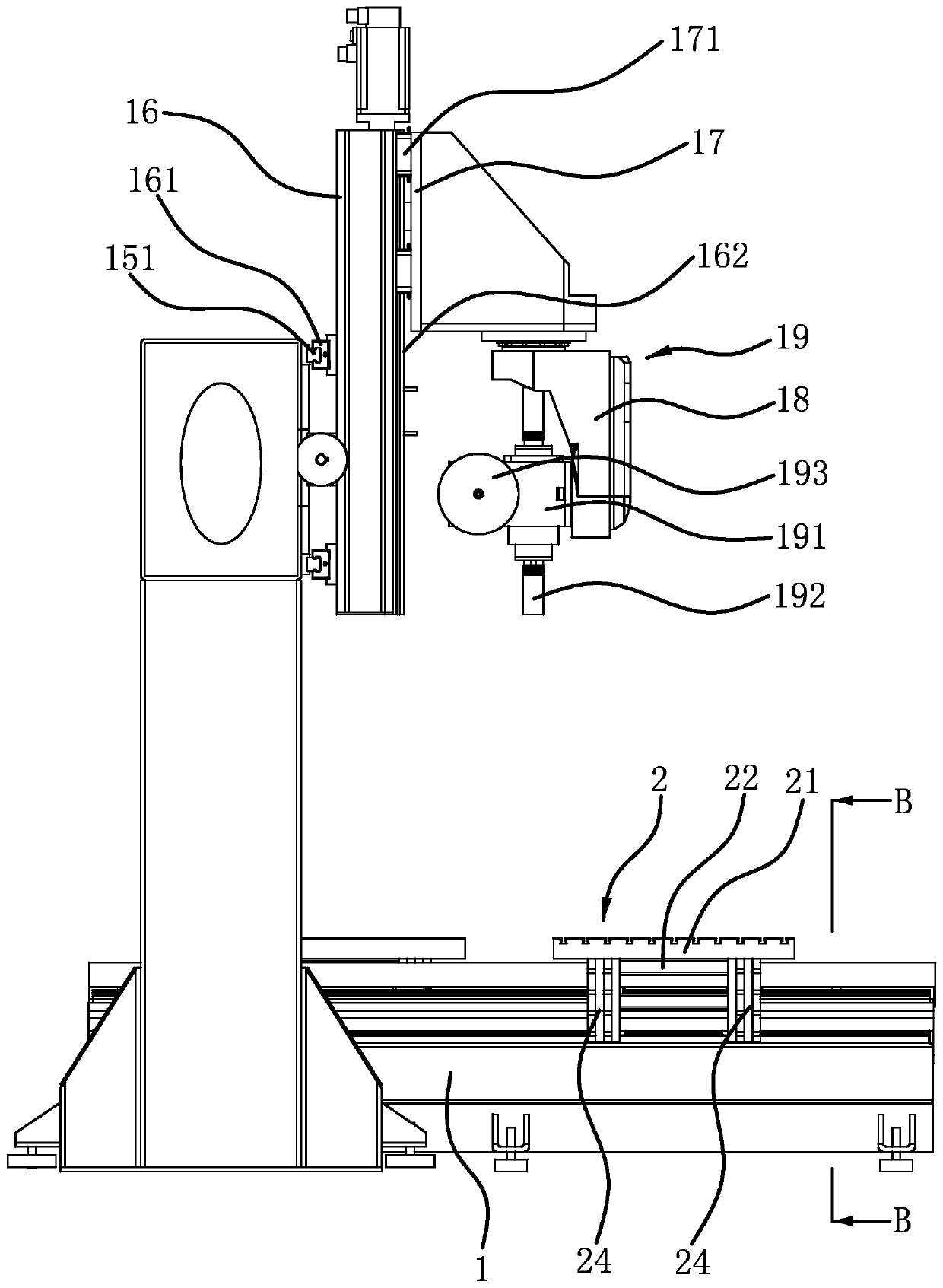

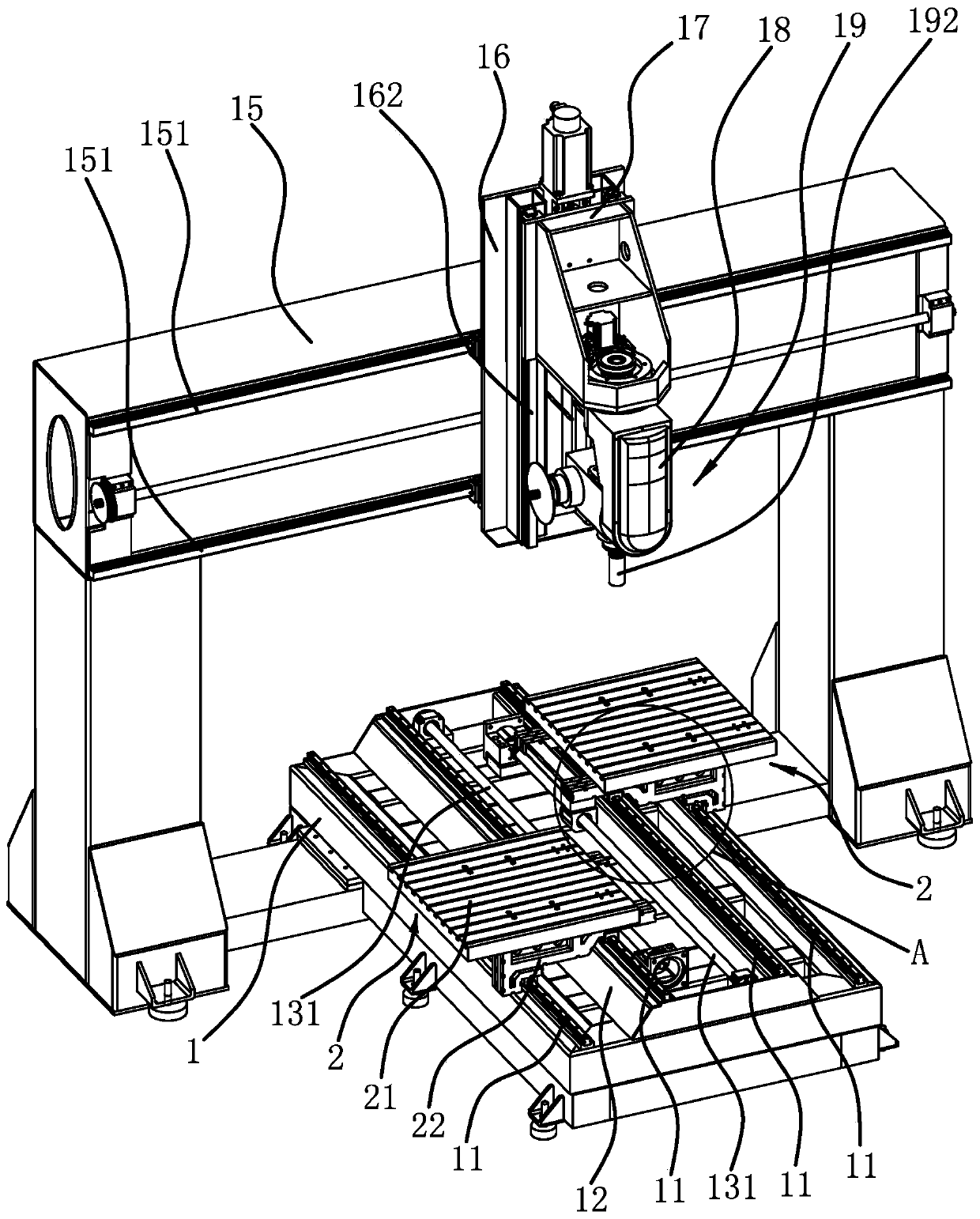

[0032] Such as figure 1 , figure 2 As shown, a kind of engraving machine comprises frame 1, processing assembly 19 and two processing tables 2, and frame 1 has the crossbeam 15 that is arranged in transverse direction, is fixed with transverse slide rail 151 along transverse direction on crossbeam 15, and transverse slide rail 151 A horizontal carriage 16 is slidably connected to the top through a horizontal slider 161, a vertical slide rail 162 is fixed vertically on the horizontal carriage 16, and a vertical carriage 17 is slidably connected to the vertical slide rail 162 through a vertical slider 171. , the vertical carriage 17 is rotatably connected with a rotary seat 18, the rotary axis of the rotary seat 18 is arranged vertically, and the processing assembly 19 includes a processing motor 191 and a cutter head 192 and a saw disc 193 installed on the processing motor 191, The processing motor 191 is rotatably connected to the rotating seat 18, and the rotation axis of t...

Embodiment 2

[0035] The structure of this engraving machine is basically the same as that of Embodiment 1, the difference is that Figure 8 As shown, both ends of the beam 15 have uprights 152 , and the front side of one of the uprights 152 is provided with a tool magazine 5 .

Embodiment 3

[0037] The structure of this engraving machine is basically the same as that of Embodiment 1, the difference is that Figure 9 As shown, the two ends of crossbeam 15 all have column 152, and the front side of one of column 152 is provided with tool storehouse 5, and the axis of rotation of rotating base 18 is vertically arranged, and the axis of rotation of processing motor 191 form an angle with the horizontal plane.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap