Inductively triggered stereoscopic warehouse

A technology of three-dimensional warehouse and ground rail, applied in the field of three-dimensional warehouse, can solve the problems of time-consuming and laborious, goods stuck, manual debugging difficulty, etc., and achieve the effect of high efficiency and convenient assembly and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

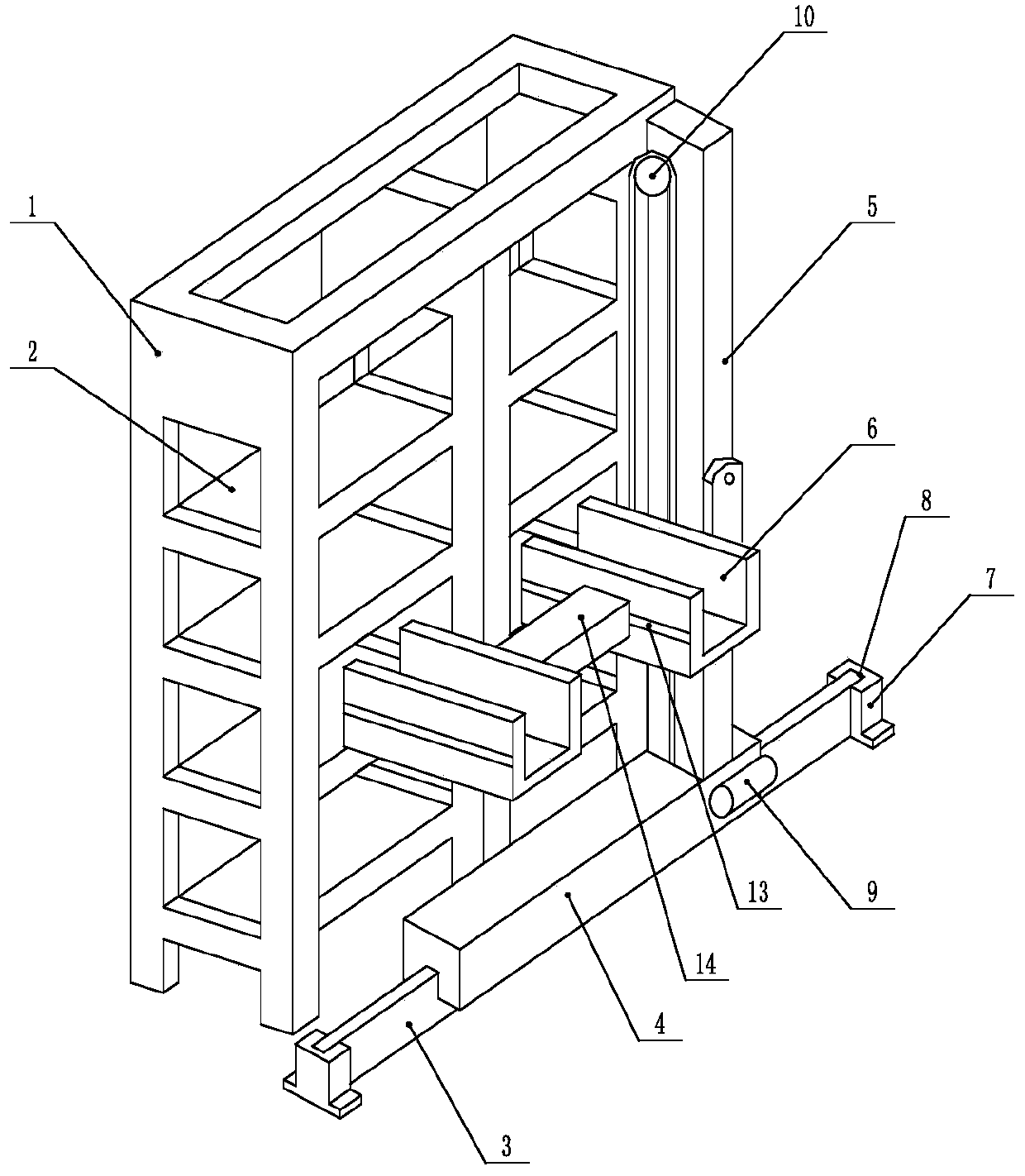

[0036] like Figure 1 to Figure 5 As shown, an induction-triggered three-dimensional warehouse of the present invention includes a shelf 1, which is provided with several layers from top to bottom, and each layer is provided with a plurality of storage boards 2, and one side of the shelf 1 is provided with a ground rail 3, and on the ground rail 3 A console 4 is provided, a vertical guide rail 5 is arranged on the console 4, a supporting plate 6 is arranged on the vertical guide rail 5, and fixing blocks 7 are arranged on both sides of the ground rail 3, and a groove 8 is arranged on the fixing block 7: ground The two ends of the rail 3 are respectively located in two fixed blocks 7, and the fixed blocks 7 can be fixed on the ground by threaded fasteners;

[0037] The bottom of the console 4 is provided with a chute, and one end of the console 4 is provided with a driving device-9, and the console 4 is driven by the driving device-9 to slide on the ground rail 3;

[0038] The...

Embodiment 2

[0044] This embodiment is a further improvement made on the basis of Embodiment 1.

[0045] like figure 1 , Figure 4As shown, the present invention is an inductively triggered three-dimensional warehouse, the driving device one 9 includes a motor one, a screw mandrel 15 and a nut 16, the screw mandrel 15 is arranged on the ground rail 3, and the motor one can drive the screw mandrel 15 Rotate, the nut 16 is fixed on the console 4, and when the screw mandrel 15 rotates, the console 4 moves along the ground rail 3.

Embodiment 3

[0047] This embodiment is a further improvement made on the basis of Embodiment 1.

[0048] like Figure 1 to Figure 5 As shown, the present invention is an inductively triggered three-dimensional warehouse, the driving device one 9 includes a motor two, a gear 17 and a rack 18, the rack 18 is arranged on the ground rail 3, and the gear 17 is arranged on the console 4, motor two can drive the gear 17 to rotate, and when the gear 17 rotates, the console 4 moves along the ground rail 3.

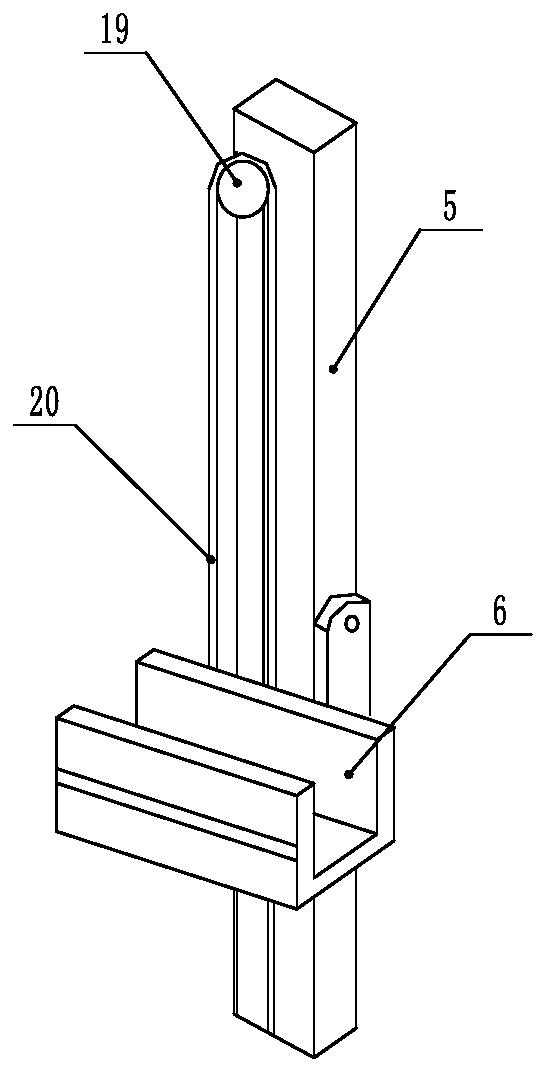

[0049] As a preferred implementation of this embodiment, the driving device 2 10 includes a winch 19 and a wire rope 20, the winch 19 is arranged on the vertical guide rail 5, one end of the wire rope 20 is connected to the supporting plate 6, and the other end is connected to the winch 19 . When the winch 19 was working, the steel rope 20 drove the supporting plate 6 to move up or down along the vertical guide rail 5 .

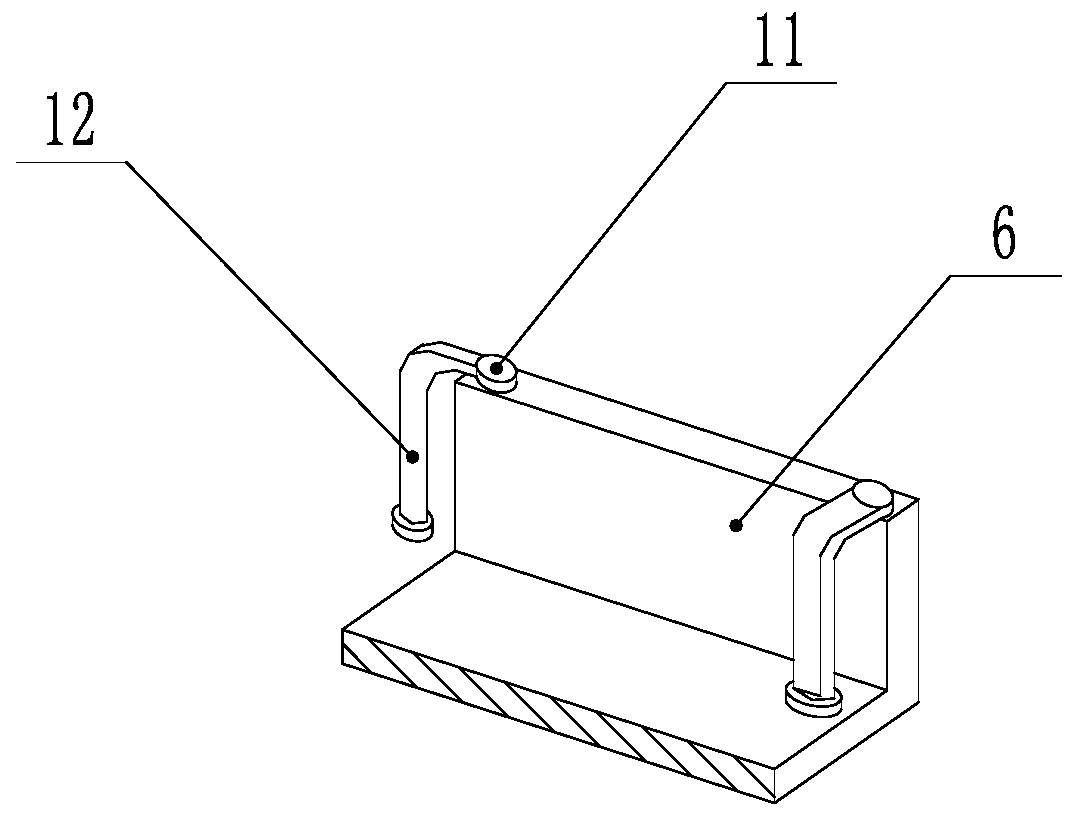

[0050] The push rod 12 is L-shaped, and the vertical length is less th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com