Transformer operation state on-line monitoring system and multi-parameter intelligent sensor thereof

An intelligent sensor, multi-parameter technology, applied in the field of electric power and communication, can solve the problems of large installation and maintenance costs, no instructions or reports found, high labor intensity, etc., to reduce labor and material expenditure, easy analysis and judgment, and reasonable detection The effect of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The following is a detailed description of the embodiments of the present invention: this embodiment is implemented on the premise of the technical solution of the present invention, and provides detailed implementation methods and specific operation processes. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention, and these all belong to the protection scope of the present invention.

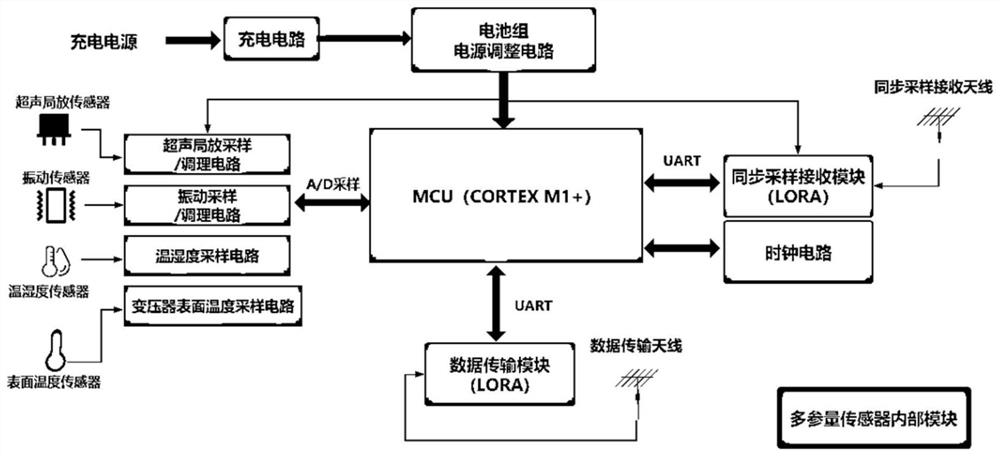

[0056] figure 1 A block diagram of the internal structure of a multi-parameter smart sensor provided by an embodiment of the present invention.

[0057] Such as figure 1 As shown, the multi-parameter smart sensor provided by this embodiment can include: multiple types of sensor modules, A / D acquisition modules, MCU control modules and power supply modules; multiple types of sensor modules are connected to the MCU control module through the A / D acquisition module, The power supply modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com