Method for enhancing salt cavern storage utilization rates by utilizing connected wells to discharge brine from bottom of cavity

A technology for connecting wells and utilization rates, which is applied in earth-moving drilling, wellbore/well components, and production fluids. and other problems, to achieve the effect of improving the utilization rate of the dissolution cavity and increasing the volume of the storage tank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

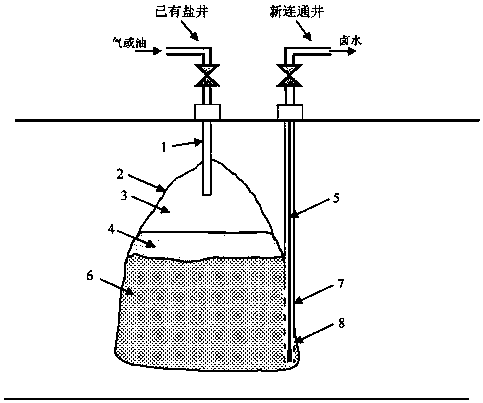

[0043] (1) In the well mine salt mine area, the volume of A salt well is 250,000 m 3 , the shape and tightness of the salt well dissolution cavity meet the technical requirements of the salt cavern gas storage, and the injection and production strings already exist in the salt well.

[0044] (2) Using sonar cavity measurement technology, the cavity top position of Well A's dissolution cavity has been determined to be -1050m, and the cavity bottom position is -1110m.

[0045] (3) A new well A' is drilled at a distance of 50m from the wellhead of Well A. The bottom of Well A' is connected to the deepest part of the dissolution cavity of Well A, and the two salt wells A and A' form a connected well. Casing and cementing are run in well A', and screen holes are set in the lower part of the casing to establish hydraulic connection between A' and well A's solution cavity. The electric submersible pump and the corresponding brine discharge pipe are lowered into the well A', and the ...

Embodiment 2

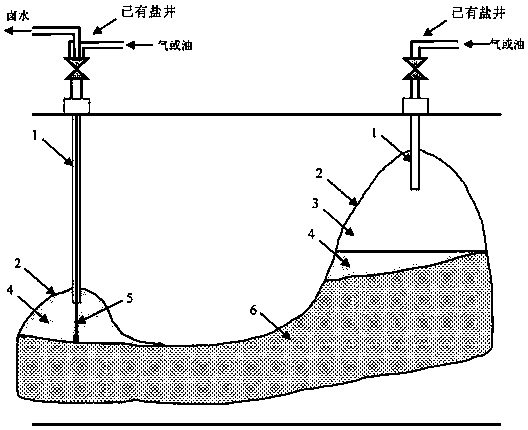

[0050] (1) In the Jingkuang salt mine area, two salt wells A and B form a group of connected wells, and the total volume of the two salt wells is 300,000 m 3 , the shape and tightness of the salt well dissolution cavity meet the technical requirements of the salt cavern gas storage, and the injection and production strings already exist in the salt well.

[0051] (2) Using sonar cavity measurement technology, the top position of the dissolved cavity of Well A is -1085m, the position of the bottom of the cavity is -1100m, the position of the top position of the dissolved cavity of Well B is -1050m, and the position of the bottom of the cavity is -1090m.

[0052] (3) Well A is selected as a "brine discharge well", and an electric submersible pump and corresponding brine discharge pipes are lowered into its injection-production string.

[0053] (4) Through the electric submersible pump, the brine in the dissolved cavity is discharged from Well A to the ground; at the same time, n...

Embodiment 3

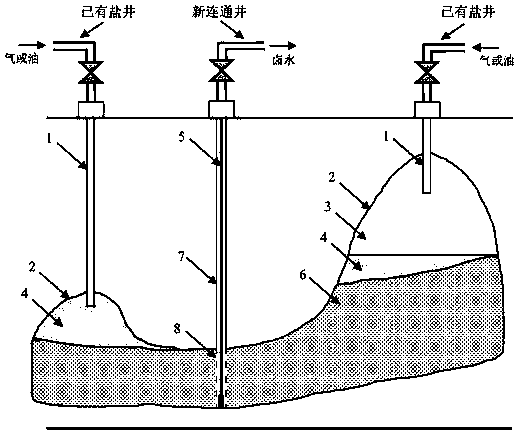

[0057] (1) In the Jingkuang salt mine area, two salt wells A and B form a group of connected wells, and the total volume of the two salt wells is 450,000 m 3 , The shape and tightness of the salt well dissolution cavity meet the technical requirements of the salt cavern oil storage depot, and the injection-production string has already been installed in the salt well.

[0058] (2) Using sonar cavity measurement technology, the top position of the dissolved cavity of Well A is -1040m, the position of the bottom of the cavity is -1090m, the position of the top of the dissolved cavity of Well B is -1085m, and the position of the bottom of the cavity is -1100m.

[0059] (3) Drill a new connecting well B' at a distance of 70m from the wellhead of Well B, and the bottom of Well B' is connected to the deepest part of the existing dissolution cavity. Run the casing in the B' well and cement the well, and set up screen holes in the lower part of the casing to establish a hydraulic conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com