High-precision testing method for interface contact thermal resistance

A testing method, a technology of contact thermal resistance, applied in the testing field, can solve problems such as not being perfect, and achieve the effect of improving testing accuracy and high-precision testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The high-precision testing method of interface thermal resistance of the present invention, concrete steps are as follows:

[0034] The first step, the preparation of test equipment:

[0035] The upper and lower samples to be tested are processed, and the upper and lower samples are installed between the heating body and the cooling block. Between the blocks, add two heat flow meters;

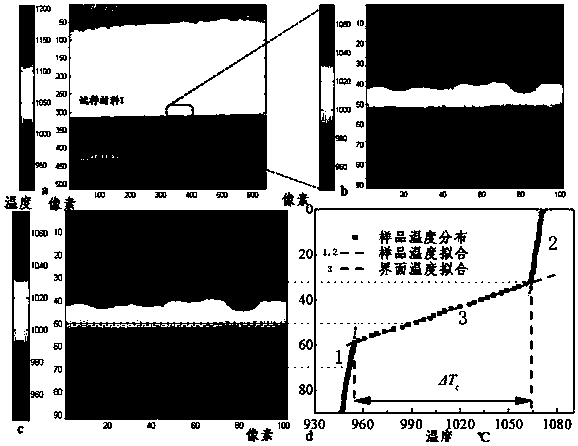

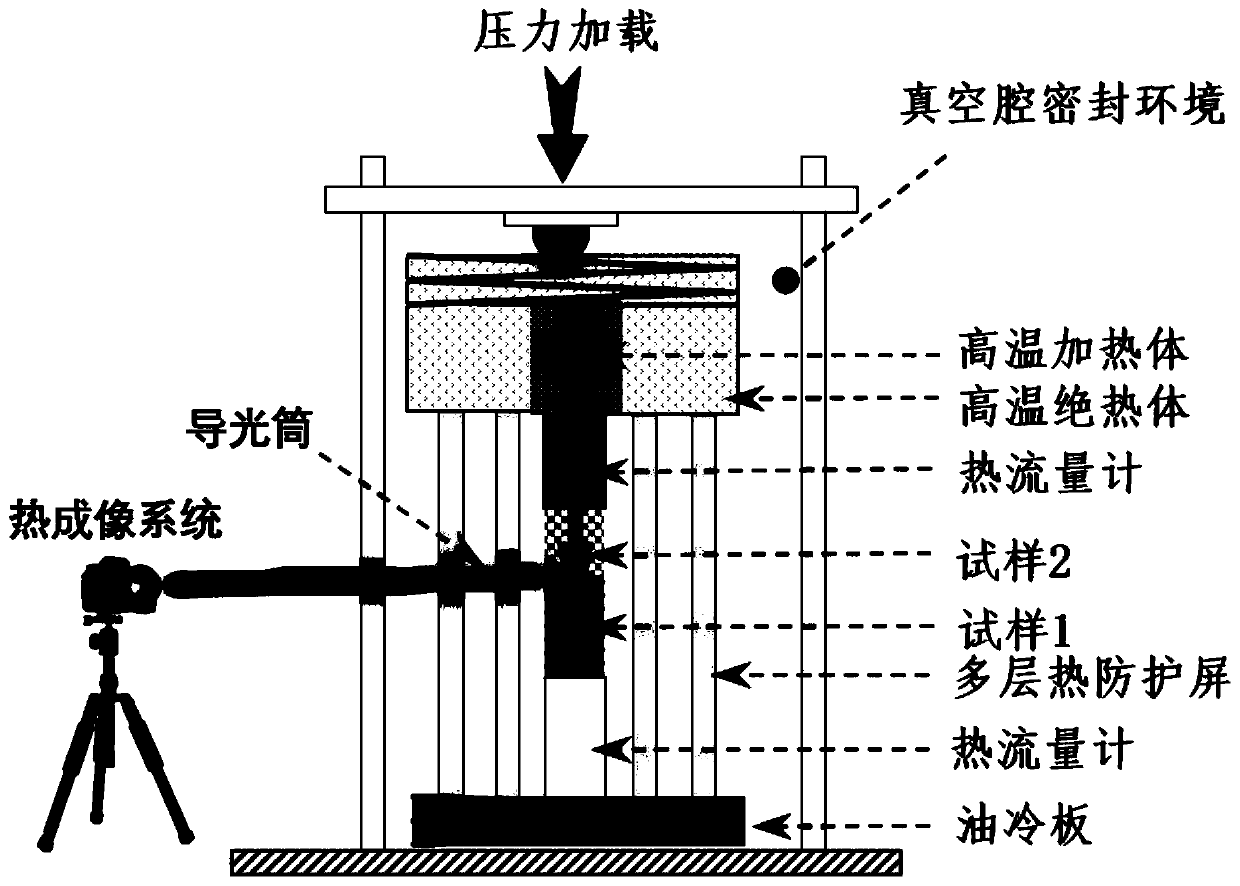

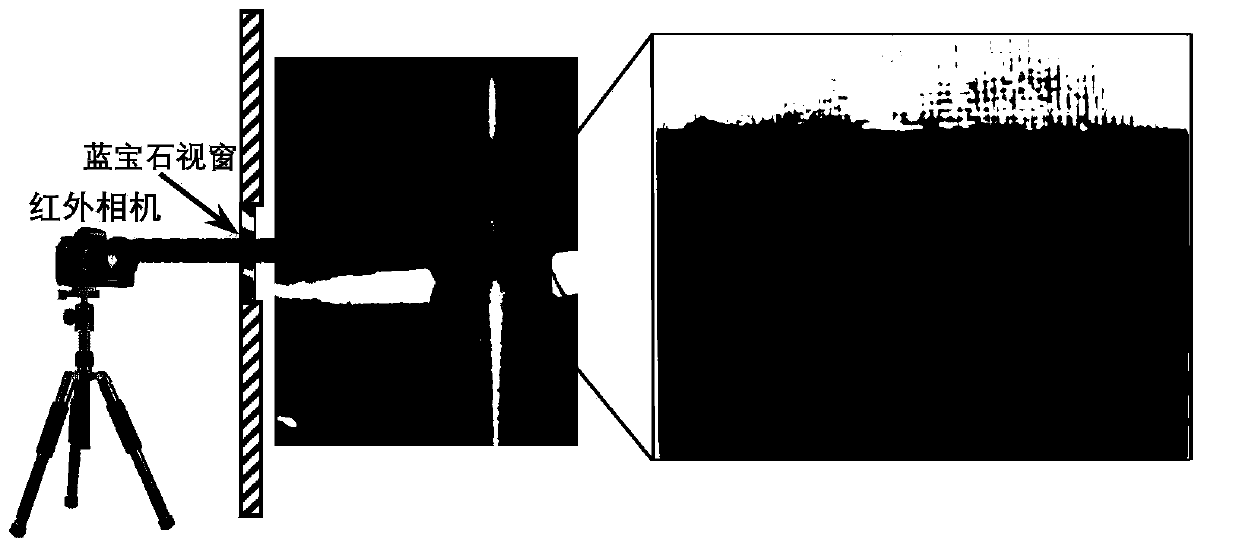

[0036] The structure diagram of the testing device of the present invention is as follows: figure 1 As shown, the test device is similar to the American National Standard ASTM E1225, and further upgrades have been made on the basis of it to improve the test accuracy. For example, to prevent heat loss, a multi-layer heat protection screen is added, and the entire test area is placed in a vacuum chamber. The contact interface temperature of the material sample pair to be tested is measured by a thermal imaging system. figure 1 Sample 1 in the formula corresponds to the lower sample to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com