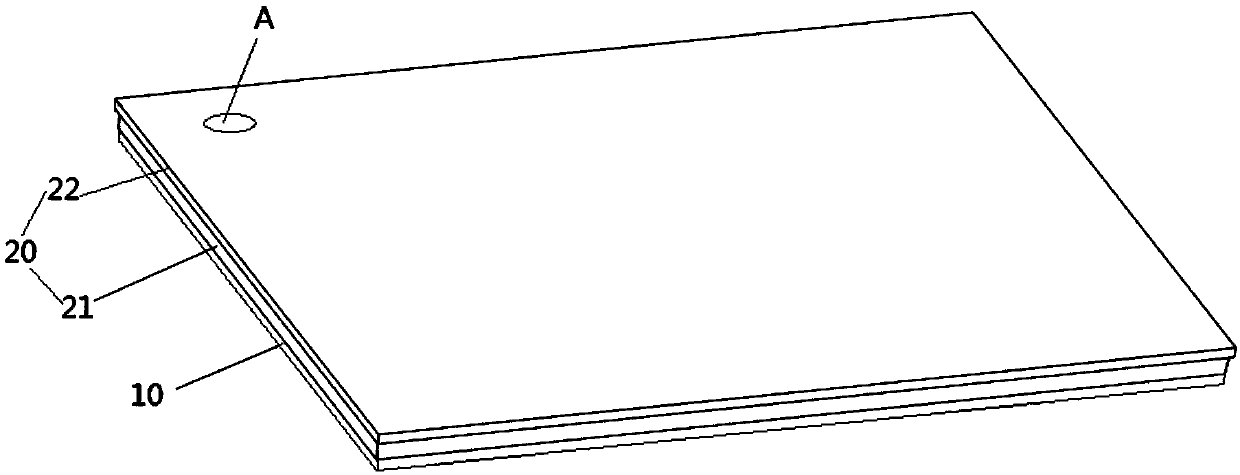

Small-space LED display module and manufacturing method thereof

A technology for display modules and manufacturing methods, which is applied in the direction of instruments, identification devices, etc., can solve the problems of high cost and low reliability, and achieve the effects of easy cleaning, convenient and reliable processing, and simple processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] In this embodiment, a small-pitch LED display module is produced, and the specific process is as follows:

[0048] Select the LED light board with model TVH2.5 set on the mounting substrate, the LED dot pitch is 2.5mm, and the size is 200×150mm;

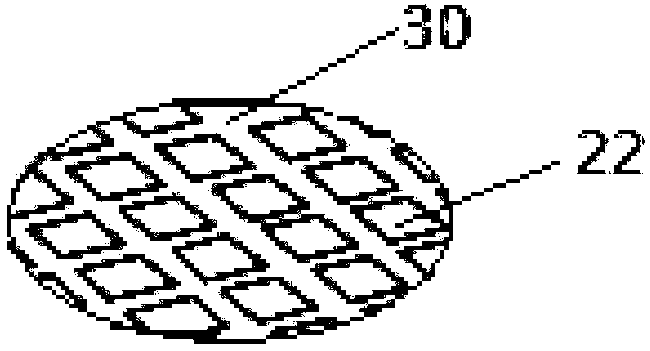

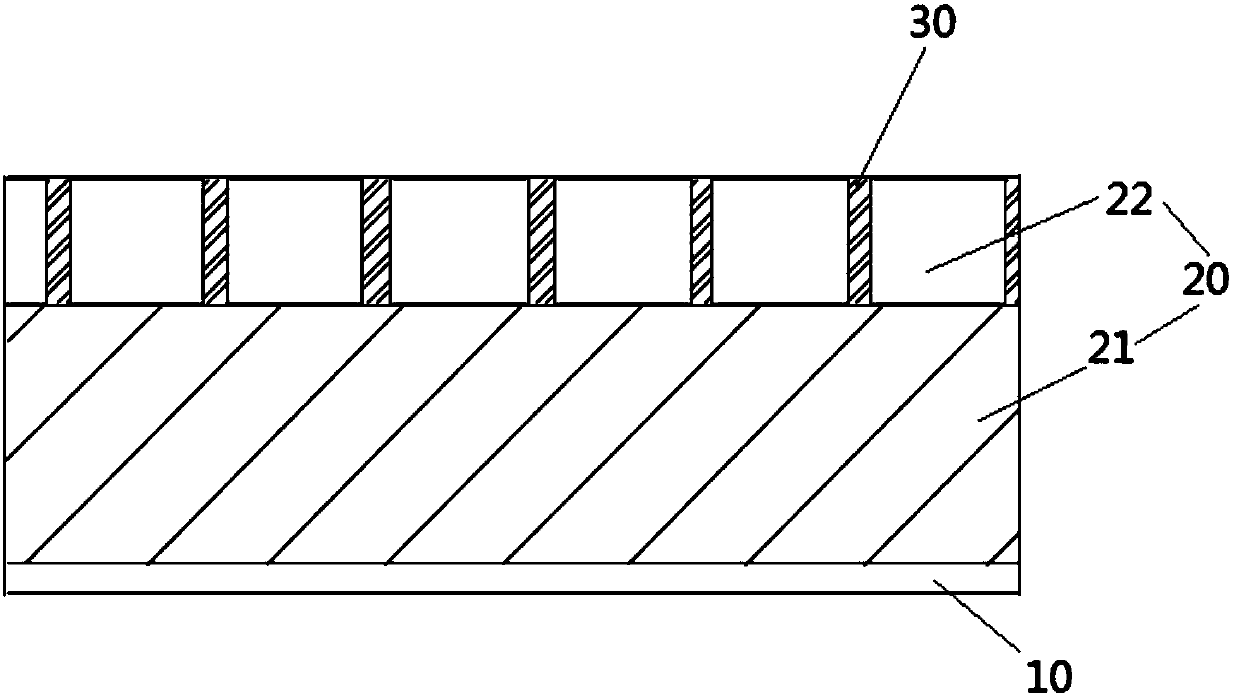

[0049] Use room temperature curing epoxy resin glue to fill the side of the LED light board away from the mounting substrate;

[0050] Secondly, use a polytetrafluoroethylene plate (thickness 1mm) to press the side carrying the glue (pressure 0.04MPa), make the glue enter the gap between the LEDs and squeeze out the excess glue, and then cure ( 6h) to form a protective colloid, and then form a prefabricated module.

[0051] Remove the frosted board in the prefabricated module to form a small-pitch LED display module.

[0052] The performance of the above-mentioned small-pitch LED display module was characterized, and the reflectance of the surface of the module was detected by a reflectance detector, and the reflectance of v...

Embodiment 2

[0054] The manufacturing process of the small-pitch LED display module in this embodiment is the same as that in Embodiment 1, the difference lies in:

[0055] The thickness of the polytetrafluoroethylene plate is 0.1mm, the pressing pressure is 0.005MPa, and the curing time is 0.5h. The performance of the above-mentioned small-pitch LED display module was characterized, and the reflectance of visible light was 1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com