fastening parts for vehicles

A technology of fastening parts and fastening, which is applied in the direction of vehicle parts, special positions of vehicles, vehicle seats, etc., and can solve the problems of small contact area of seat frame, deterioration, seat frame application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

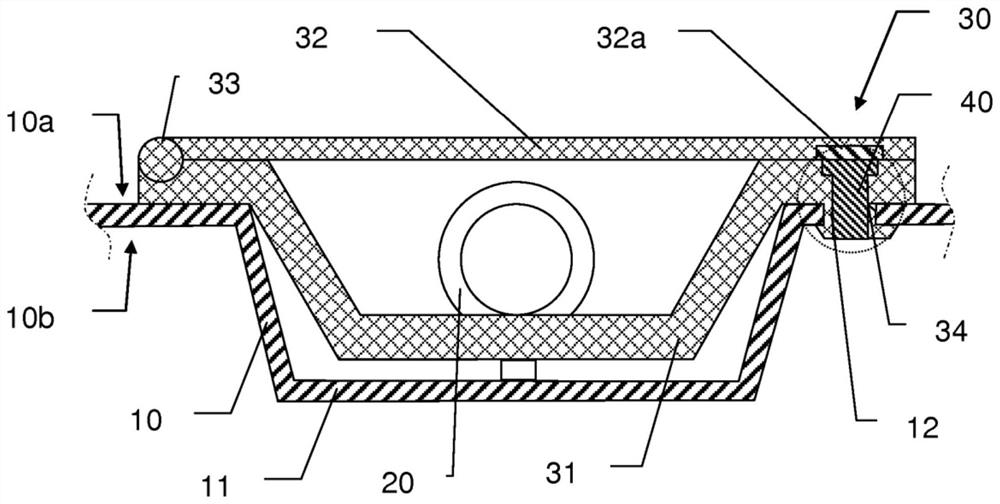

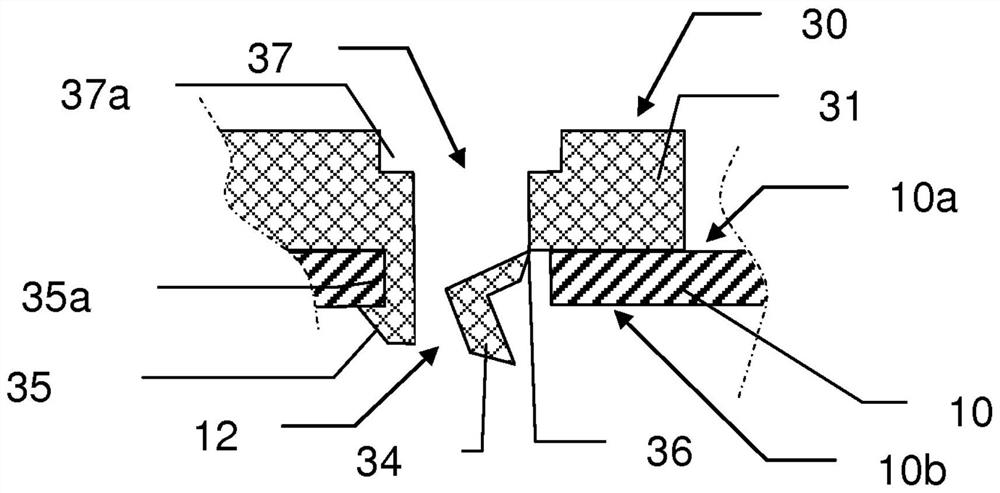

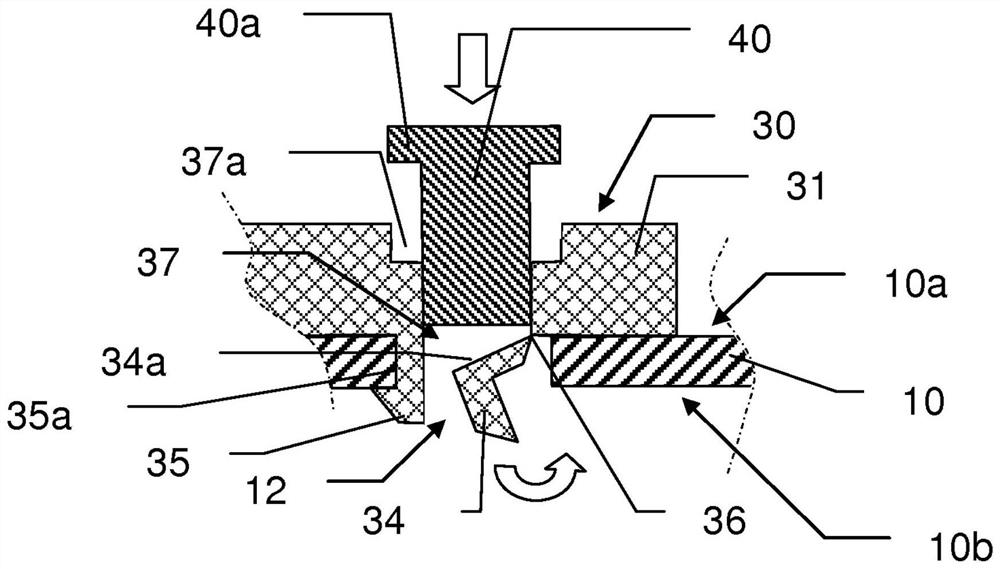

[0022] The present invention relates generally to fastening elements suitable for installation in apertures in seat frames. Thus, the fastening part can be used to fasten a seat element or any other element to such a frame. Additionally, fastening elements may be integrated into cockpit elements such as the housing for the safety hook, as described below.

[0023] therefore, figure 1 A seat frame wall 10 is shown comprising a first surface 10a oriented towards the cockpit of the vehicle and a second surface 10b oriented towards the interior of the seat. Furthermore, the wall 10 forms a chamber 11 in which a safety hook 20 is arranged. The safety hook 20 acts as a third locking point, eg an ISOFIX or LATCH type fastening part, for attaching the infant seat on the vehicle seat, for example. Furthermore, such hooks can be used as locking points for hooking luggage or bulky loads in the cockpit of a vehicle.

[0024] For aesthetic reasons but also for safety reasons, the chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com