A kind of polyeugenol-phenylsilsesquioxane and preparation method thereof

A technology of phenyl sesquioxane and phenyl trialkoxysilane, which is applied in the field of polyeugenol-phenyl silsesquioxane and its preparation, can solve the problem of affecting the impact strength of composite materials, polyphenyl silsesquioxane alkane precipitation, poor compatibility and other problems, to achieve the effect of improving dispersion, improving impact strength and precipitation resistance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Preparation of polymercapto-phenylsilsesquioxane:

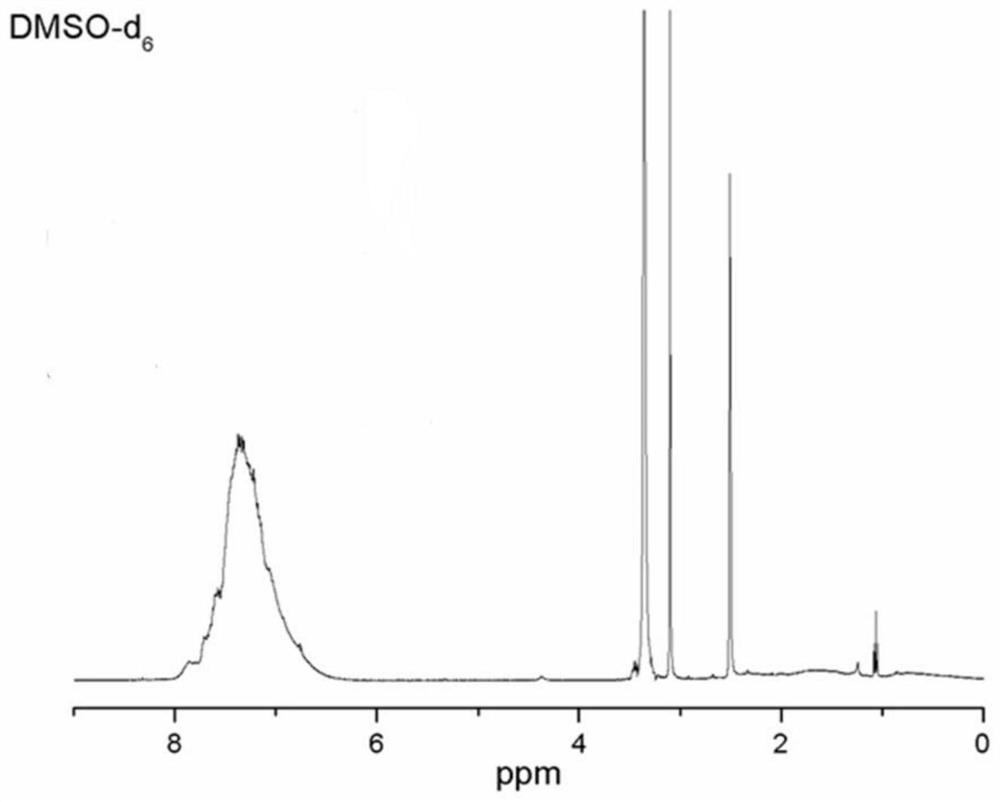

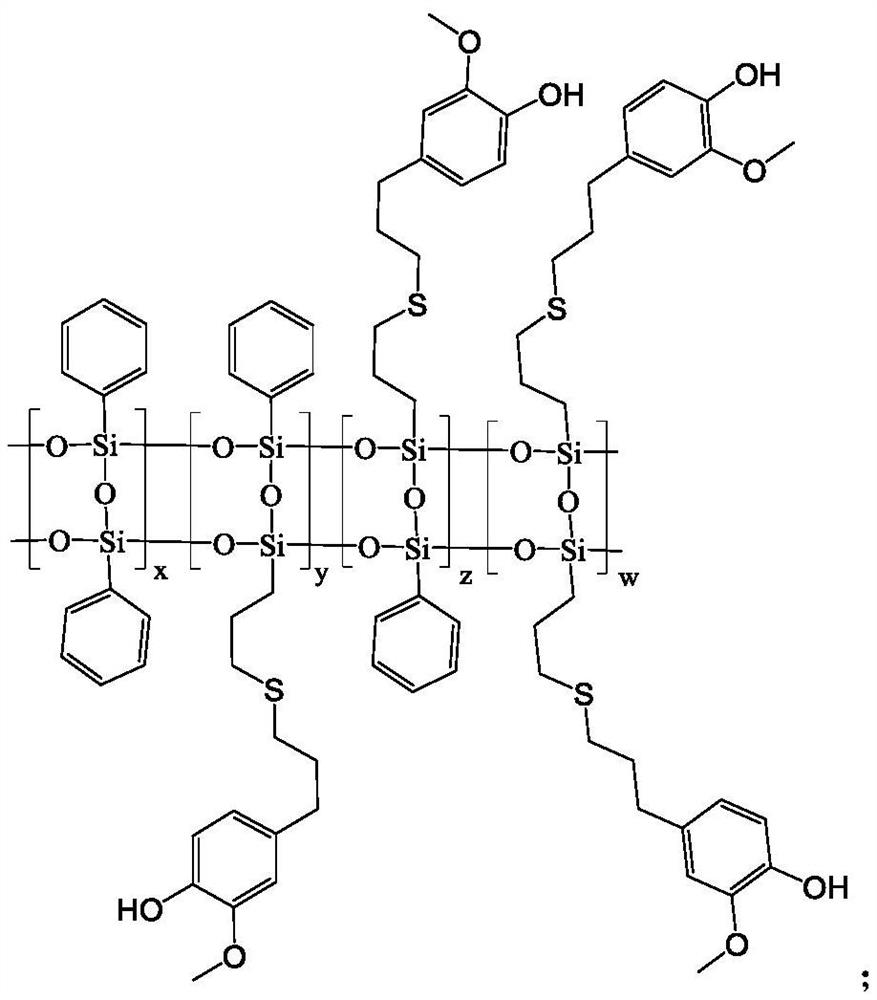

[0033] At room temperature, in a 250L three-necked flask, add 150L of water, 1kg of sodium lauryl sulfate, 1L of 25wt% aqueous solution of tetramethylammonium hydroxide, 4L of mercaptopropyl triethoxysilane and 16L of phenyl triethoxysilane After the ethoxysiloxane is mixed evenly, it is added dropwise to the three-necked flask under stirring, and the reaction is continued for 10 hours after the addition of 2 hours, centrifuged, the obtained precipitate is washed with water and then separated, and the powder is obtained after drying. The nuclear magnetic spectrum is as follows: figure 1 , with the structure:

[0034]

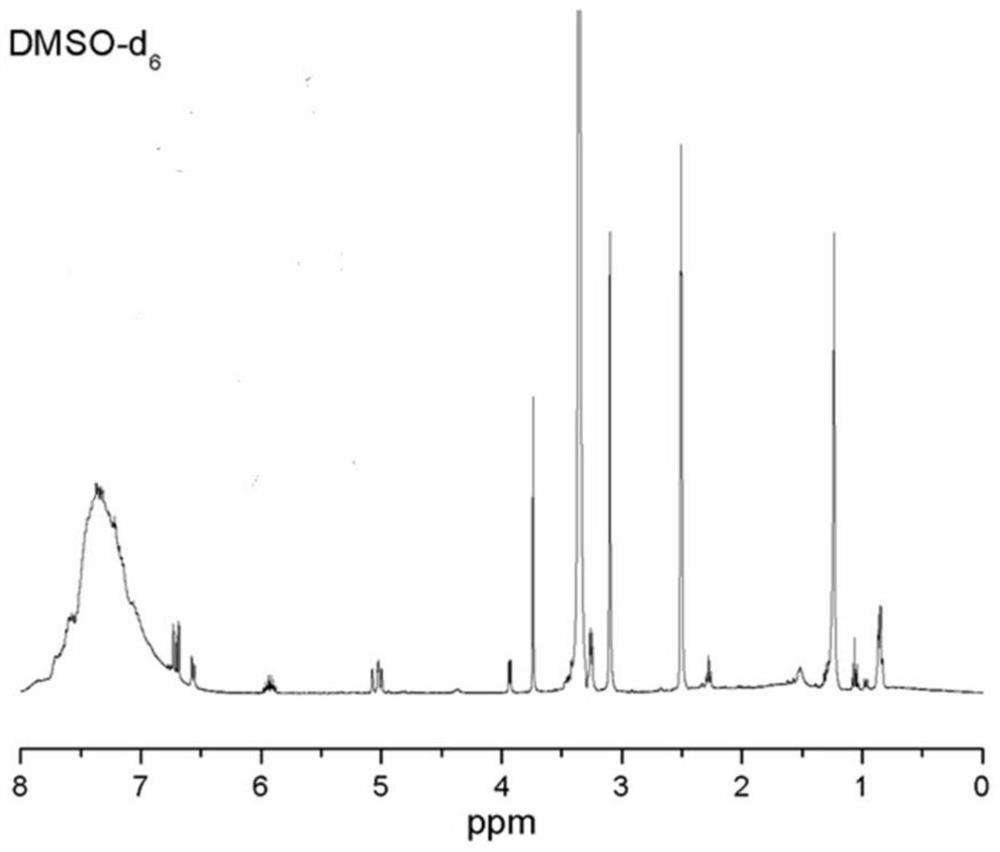

[0035] 2. Preparation of polyeugenol-phenylsilsesquioxane:

[0036] Add 10kg of polymercapto-phenylsilsesquioxane powder and 2.5kg of eugenol into a 100L three-necked flask, stir well under mechanical stirring, and then add 1-hydroxycyclohexyl phenyl ketone dissolved in 2L THF Wherein, under the ...

Embodiment 2

[0040] 1. Preparation of polymercapto-phenylsilsesquioxane:

[0041] At 40°C, add 120L of water, 1.2kg of sodium dodecylbenzenesulfonate, 1.4L of 30wt% aqueous solution of tetraethylammonium hydroxide, and 4kg of mercaptopropyl triethoxysilane in a 250L three-neck flask. After mixing evenly with 16kg of phenyltriethoxysiloxane, add it dropwise to a three-necked flask with stirring, continue to react for 15 hours after 2 hours of addition, and centrifuge to separate. The resulting precipitate is washed with water and then separated, and dried to obtain a powder.

[0042] 2. Preparation of polyeugenol-phenylsilsesquioxane:

[0043] Add 10kg of polymercapto-phenylsilsesquioxane powder and 3kg of eugenol to a 100L three-necked flask, stir well under mechanical stirring, then add benzophenone dissolved in 2L THF to it, at a wavelength of 300nm Under the irradiation of ultraviolet light, react at room temperature for 3 h. After the reaction, the solvent was evaporated to dryness a...

Embodiment 3

[0046] 1. Preparation of polymercapto-phenylsilsesquioxane:

[0047] At 30°C, add 140L of water, 1.5kg of potassium dodecylbenzenesulfonate, 1.2L of 25wt% aqueous solution of tetrabutylammonium hydroxide, 5kg of mercaptopropyltriethoxysilane and 50kg of After the phenyltrimethoxysiloxane is mixed evenly, it is added dropwise to the three-necked flask under stirring, and the reaction is continued for 8 hours after 2 hours of addition, and centrifuged, and the obtained precipitate is washed with water and then separated, and dried to obtain a powder.

[0048] 2. Preparation of polyeugenol-phenylsilsesquioxane:

[0049] Add 12kg of polymercapto-phenylsilsesquioxane powder and 4kg of eugenol to a 100L three-necked flask, stir well under mechanical stirring, and then dissolve 3,4-dimethylbenzophenone with 3L THF Add it, and react at room temperature for 4 hours under the irradiation of ultraviolet light with a wavelength of 365 nm. After the reaction, the solvent was evaporated t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com