Frame sealant composition and preparation method thereof and display device

A technology of composition and frame sealing glue, which is applied in the direction of adhesive, epoxy glue, adhesive type, etc., can solve problems such as liquid crystal outflow, poor adhesion, and bad liquid crystal display, so as to prevent liquid crystal leakage and improve quality The effect of preventing internal coagulation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

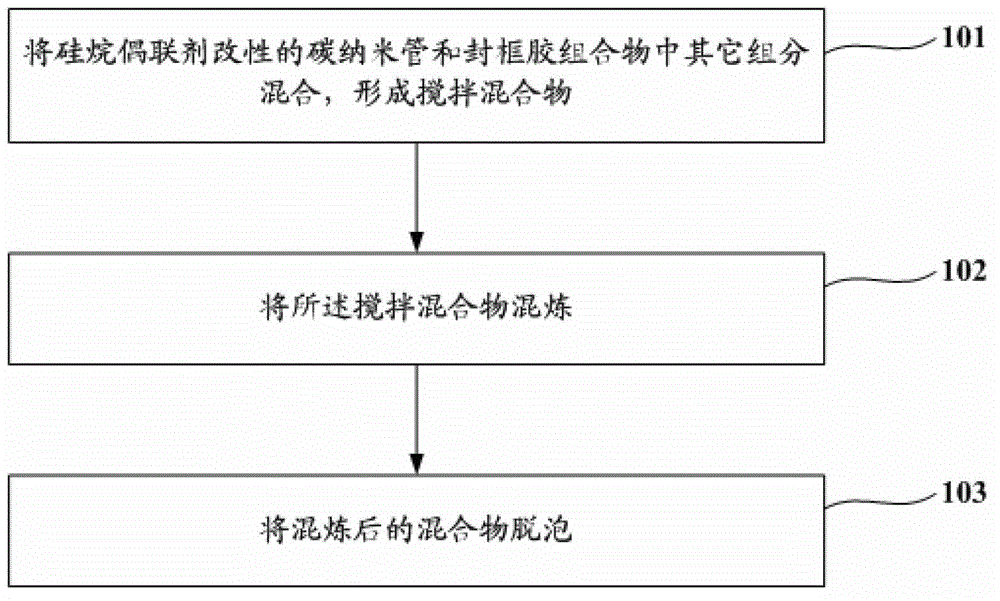

[0047] Such as figure 1 As shown, the preparation method of the sealant composition of the present invention comprises:

[0048] Step 101, mixing the carbon nanotubes modified by the silane coupling agent with other components in the sealant composition to form a stirred mixture; specifically:

[0049] Carbon nanotubes modified by silane coupling agent with a mass fraction of 1.7% to 2.1%, epoxy resin with a mass fraction of 10% to 15%, acrylic resin with a mass fraction of 60% to 70%, and a mass fraction of 0.5 %~1% of alkyl phenone photoinitiator, 5%~8% of polybasic aliphatic amine heat curing agent, 5%~10% of silica microspheres and 5% of mass fraction %~8% resin elastic microspheres are stirred at a temperature of 10~30°C for 30~60 minutes to form a stirred mixture;

[0050] Step 102, kneading the stirring mixture; specifically:

[0051] kneading the stirred mixture at 30-50°C;

[0052] Step 103, defoaming the kneaded mixture.

[0053] Preferably, before forming the s...

Embodiment 1

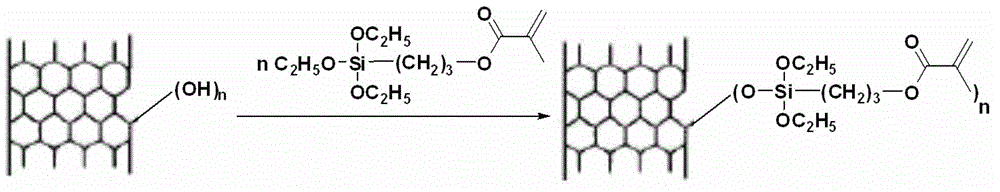

[0059] Put the mixture of TNIMH6 with a mass fraction of 0.1% and KH570 with a mass fraction of 1.9% into a 40kHz / 1000W ultrasonic oscillator for 5 to 6 hours of ultrasonic vibration treatment to form TNIMH6 modified by a silane coupling agent, that is, to obtain the mass fraction as 2% TNIMH6-KH570 complex. Fourier transform infrared spectrometer (FT-IR) was used to characterize the TNIMH6 before and after the modification of the silane coupling agent. Specifically, potassium bromide (KBr) was used to press the tablet to make samples, and the TNIMH6 before and after the modification of the silane coupling agent was tested. infrared spectroscopic data. Before modification, TNIMH6 is hydroxylated carbon nanotubes, at 3480cm -1 A strong absorption peak of hydroxyl appears at the place; after modification by KH570, at 3480 -1 The absorption peak weakens at 1082cm -1 A strong absorption peak of C-O-Si appears. This shows that after ultrasonic oscillation treatment, TNIMH6 and ...

Embodiment 2

[0065] Put the mixture of TNIMH6 with a mass fraction of 0.2% and KH570 with a mass fraction of 1.5% into a 40kHz / 1000W ultrasonic oscillator for 5 to 6 hours of ultrasonic vibration treatment to form TNIMH6 modified by a silane coupling agent, that is, to obtain the mass fraction 1.7% TNIMH6-KH570 complex.

[0066] The TNIMH6-KH570 compound with a mass fraction of 1.7%, the bisphenol A epoxy resin with a mass fraction of 10%, the methacrylic resin with a mass fraction of 70%, and the alkyl phenone photosensitive resin with a mass fraction of 0.5% Initiator α-hydroxyalkyl phenone, multi-component aliphatic amine heat curing agent dimethylaminopropylamine with a mass fraction of 5%, silica microspheres with a mass fraction of 5%, and resin elastic microspheres with a mass fraction of 7.8% stirring at a temperature of 10 to 30°C for 30 to 60 minutes, preferably at a temperature of 20°C for 60 minutes to form a stirred mixture;

[0067] Knead the above-mentioned stirred mixture ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com