Labeling machine, printing machine, inspection machine, and method for starting up a bus system in such a machine

A bus system, technology for labelling machines, applied in the field of labelling machines, printing machines, inspection machines and for the commissioning of bus systems in such machines, which can solve problems such as high failure risks, prolonged expensive equipment shutdowns, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

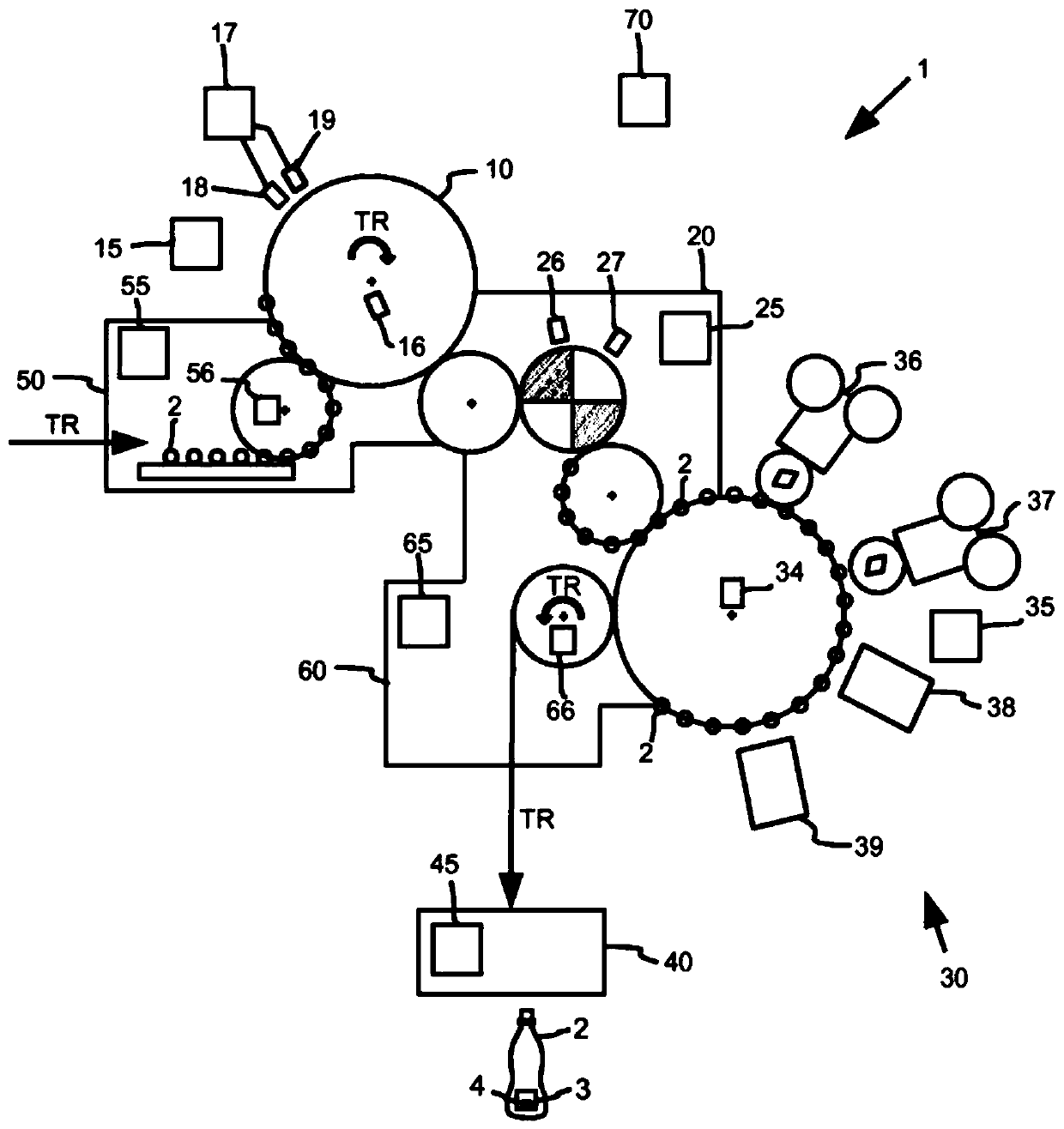

[0030] figure 1 Shown is a container treatment plant 1 for the treatment of containers 2, which may be bottles, jars, boxes, etc., which may be equipped with a very schematically shown label 3 and / or any printing 4 as characterization.

[0031] To this end, the container treatment plant 1 has as an example first to fourth container treatment machines 10 , 20 , 30 , 40 which are coupled to one another. However, it is also possible for the container treatment plant 1 to have only one or two or three of the container treatment machines 10 , 20 , 30 , 40 . There may also be more container handling machines 10 , 20 , 30 , 40 . Thus, any arbitrary number of container handling machines 10, 20, 30, 40 is possible. exist figure 1 In , not all containers 2 are shown or provided with reference numerals for the sake of brevity.

[0032] The container 2 can be, for example, a container with a volume of at most approximately 0.33 liters or 0.5 liters or 1.5 liters or the like. Of cour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com