Measuring device for measuring warp tension in a weaving machine and a weaving machine with such a measuring device

A measuring device and loom technology, applied in looms, textiles, papermaking, textiles, etc., can solve problems such as distorted measurement results and difficulties in accurately measuring warp tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

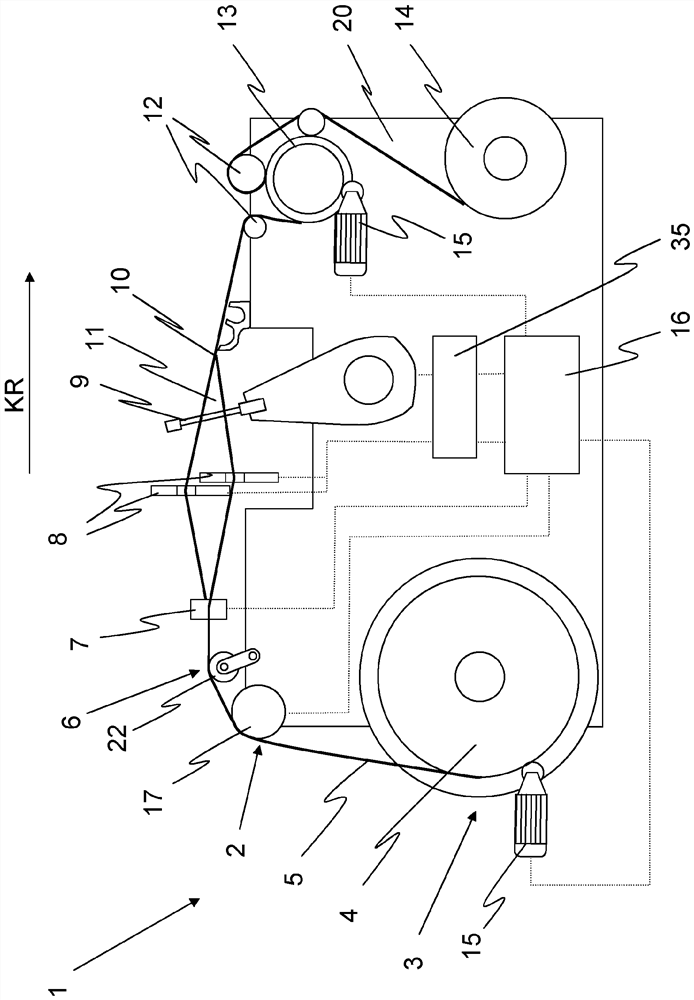

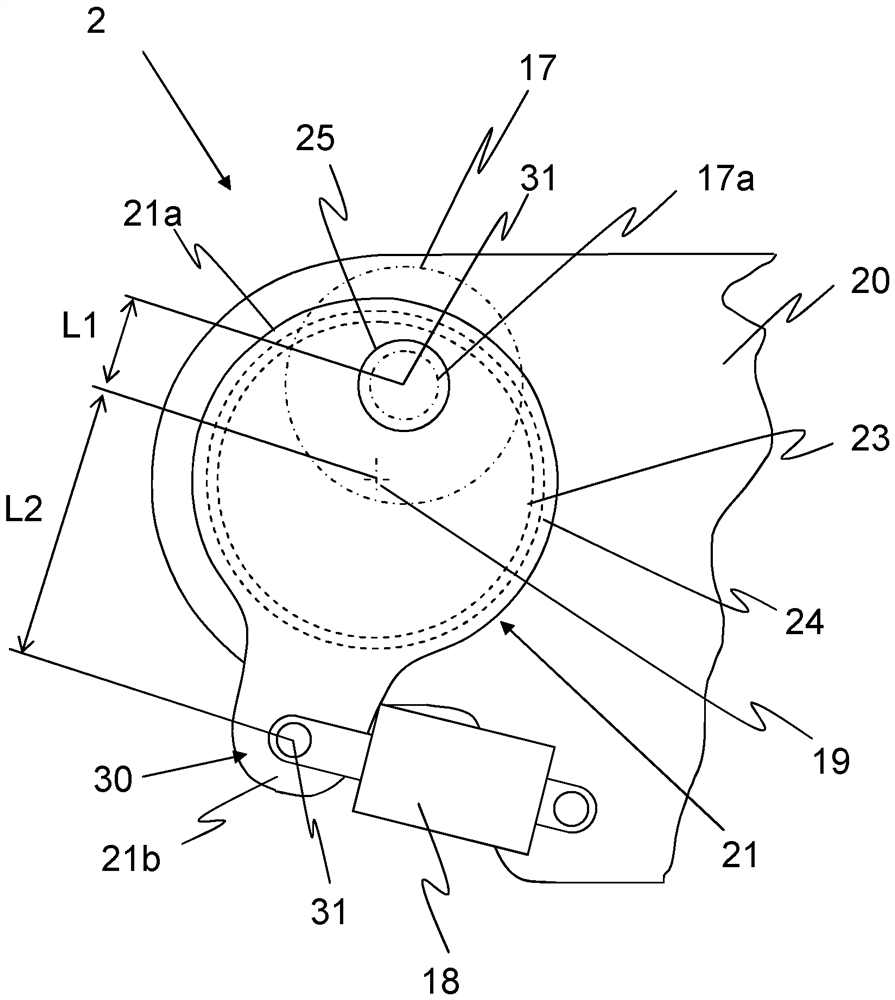

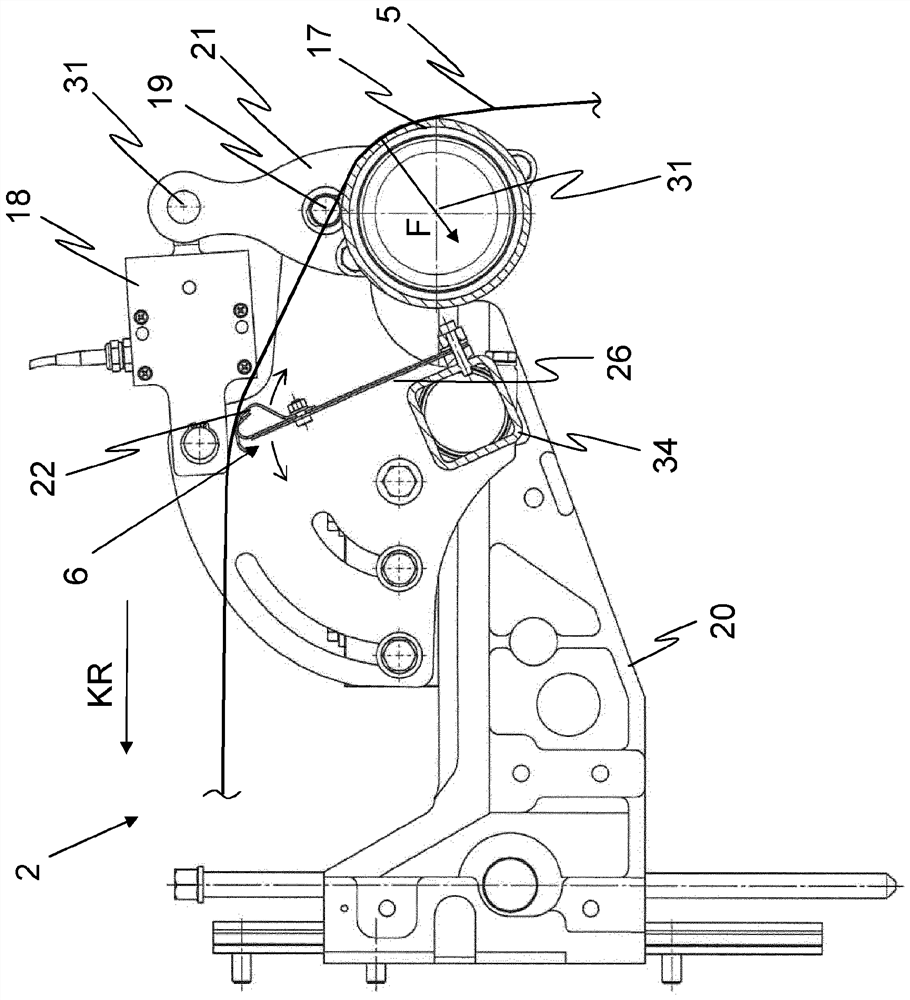

[0036] figure 1 is a schematic side view of a loom 1 equipped with a measuring device 2 for measuring warp tension. The warp thread (Kettfäden) 5 here is usually unwound (abgewickelt) from the warp beam (Kettbaum) 4 of the conveying device 3 for conveying the warp thread and passes successively in the warp direction KR (see arrow) through the measuring device 2 for measuring the warp thread tension, The backrest 6 and the warp thread monitor 7 feed a shedding device 8 , which are usually oscillating and movable relative to one another in order to form a shed 11 . The rear rest has deflection elements 22 and can be designed in different ways, as will be explained in more detail with reference to the following figures. The weft insertion device is not shown, which can be designed in different ways and is sufficiently known in the prior art. Furthermore, the loom has a weaving reed (Webblatt) 9 , by means of which the inserted weft thread (Schussfaden) can be punched (angeschla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com