Dust collecting device for dust of magnet processing workshop

A technology of dust removal device and processing workshop, applied in the field of dust removal device and dust removal device, can solve the problems of frequent filter replacement and low magnetic dust removal efficiency, and achieve the effect of long service life, reducing blockage and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

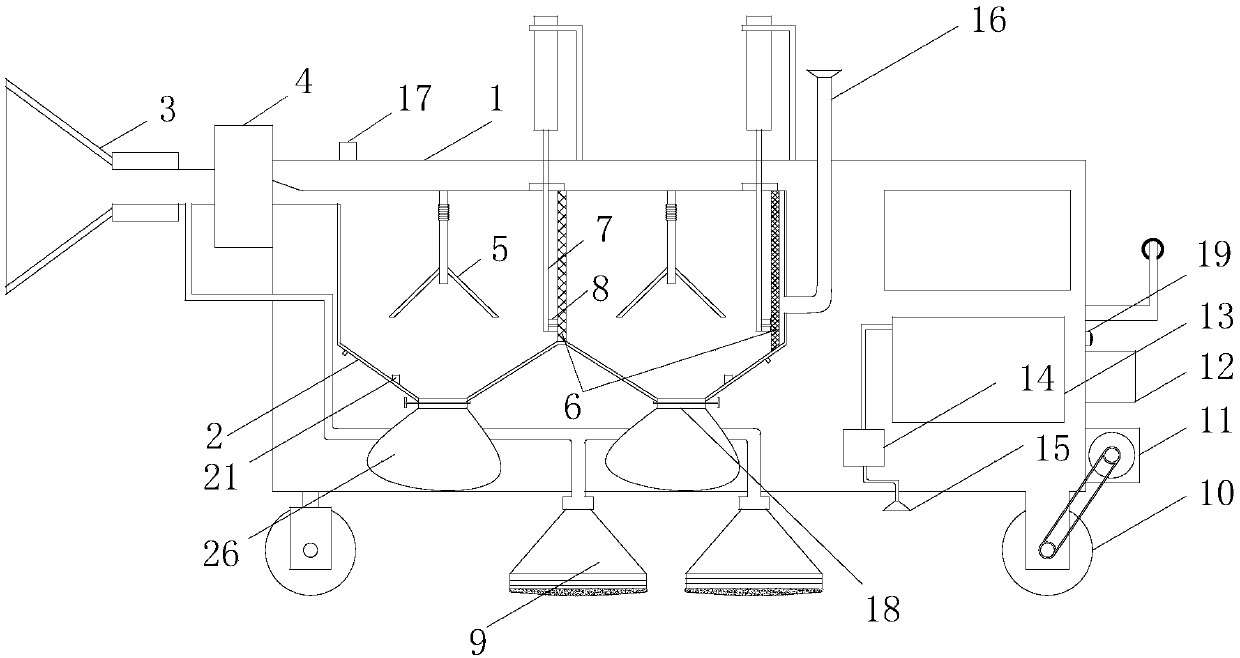

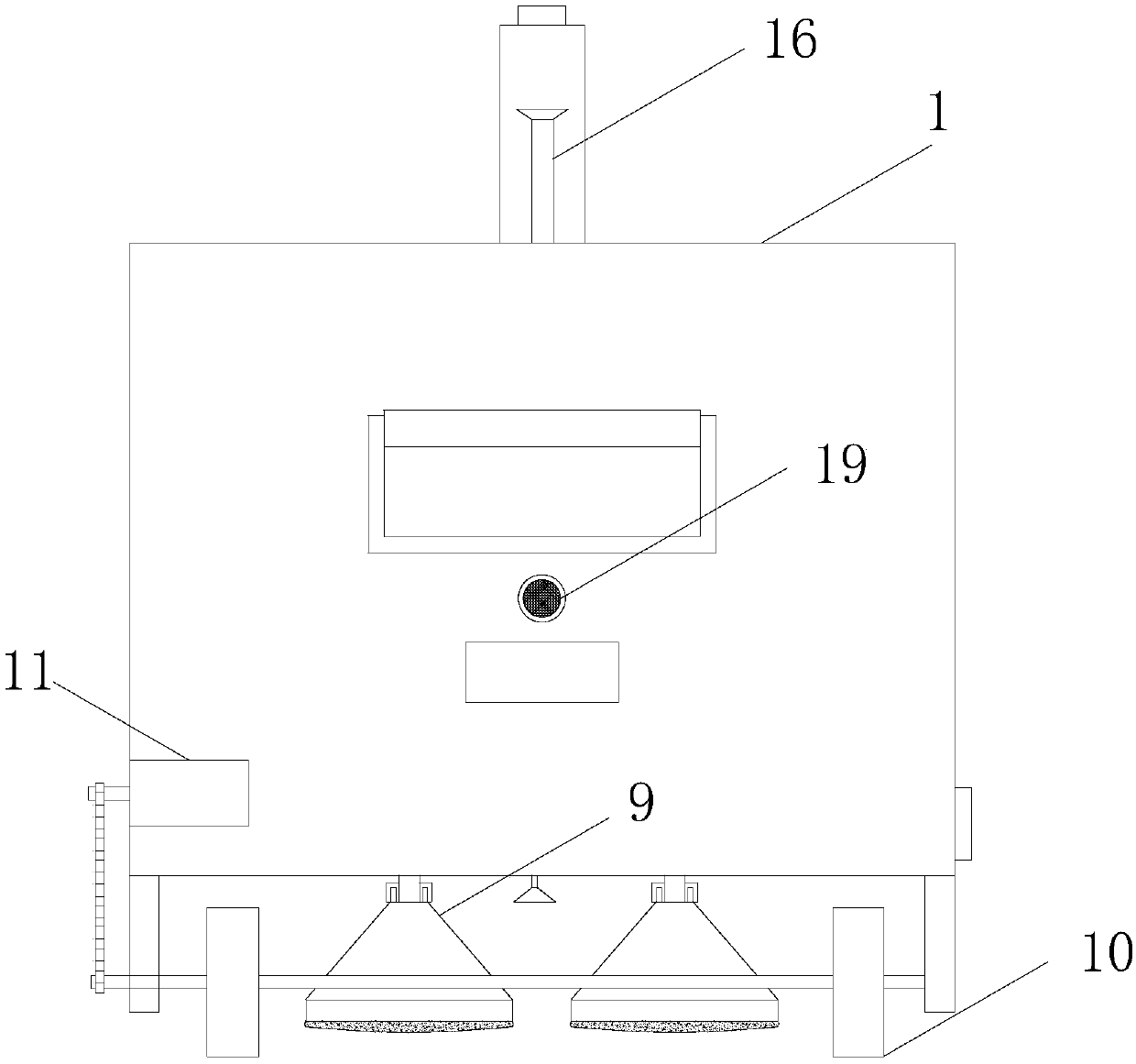

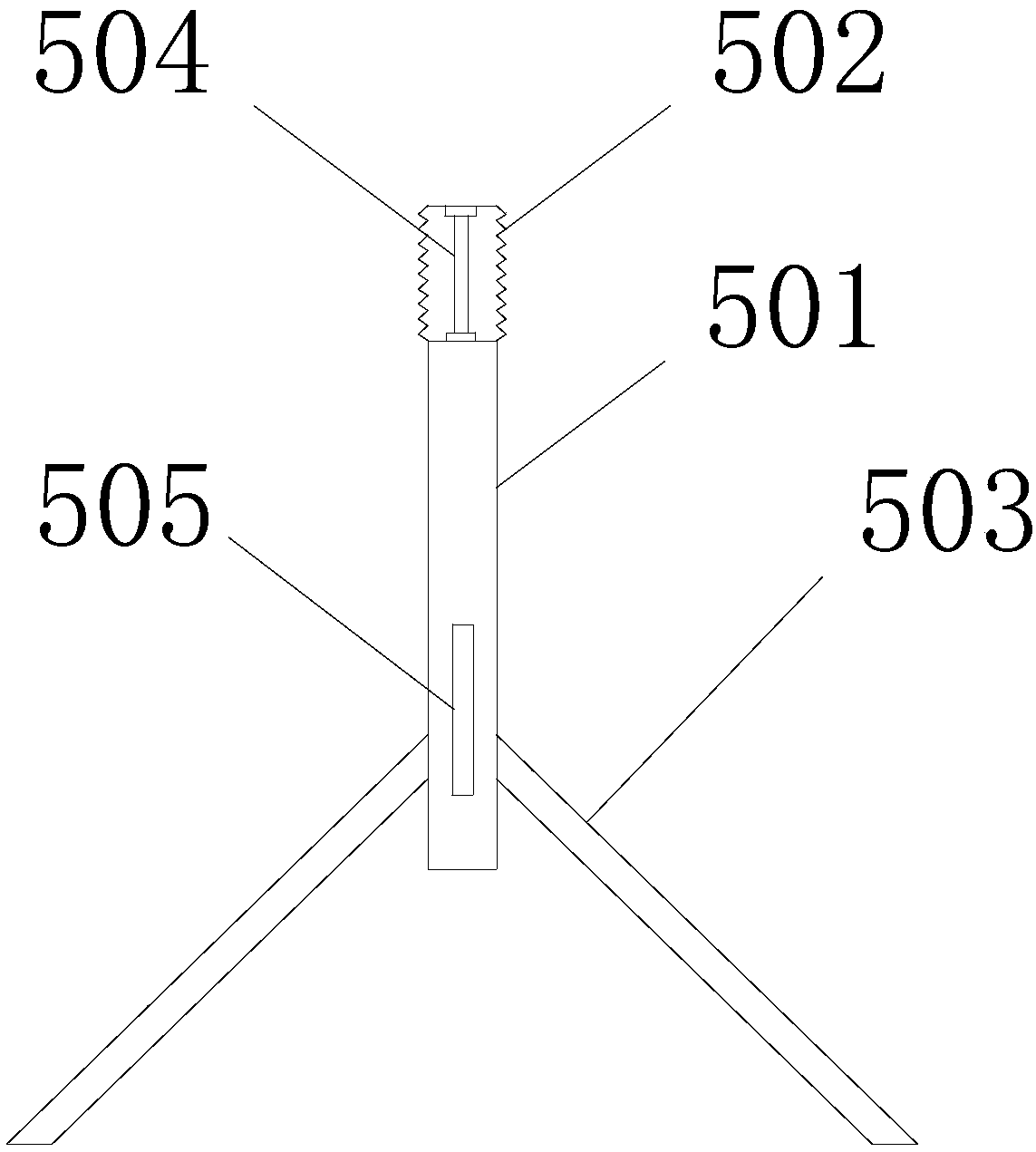

[0056] see figure 1 and figure 2 , The dust removal device for the dust in the magnet processing workshop of the present embodiment includes a casing 1, a drive mechanism, a dust collection mechanism, a storage mechanism, an adsorption device 5, a dust collection cover 9, a cleaning mechanism, a dust detector-17, a controller 12. Spray mechanism.

[0057] The box body 1 adopts a square box body and a hollow structure inside.

[0058] The drive mechanism is used to drive the box body 1 to travel. The driving mechanism may include a motor 11 and a plurality of driving wheels 10 arranged at the bottom of the box body 1 . A plurality of driving rollers 10 are divided into two groups of driving wheels. The driving wheels 10 in the same driving wheel group are connected to the casing 1 through a wheel shaft, and the two groups of driving wheels are respectively arranged at opposite ends of the casing 1 . The motor 11 is arranged at one end of the casing 1, and the motor shaft i...

Embodiment 2

[0071] see Figure 4 and Figure 5 , The dust removal device for the dust in the magnet processing workshop of this embodiment adds a flushing mechanism and a collection box 23 on the basis of Embodiment 1, and removes the cloth bag 26 and the pressure sensor 2 25 .

[0072] The flushing mechanism includes a water pump two 22 connected to the water storage tank 13, and the outlet pipes of the water pump two 22 are connected to two spray pipes 24 respectively corresponding to two compartments, and the other end of each spray pipe 24 stretches into the corresponding compartment and is equipped with When a rotating nozzle needs to wash the compartment, the cloth bag 26 is removed first, and each nozzle 24 sprays high-pressure water through the rotating nozzle, thereby flushing the corresponding compartment, and the waste water is discharged through the discharge pipe 18.

[0073] The top of the collection box 23 is connected to all discharge pipes 18, thereby collecting the dust...

Embodiment 3

[0075] see Figure 6 In the present embodiment, the hydraulic rod 7 in the embodiment 1 is replaced by a manually operable extension rod 27 in the dust removal device for dust in the magnet processing workshop, and the operator can regularly clean the filter screen 6, saving dust removal. The manufacturing cost of the device also saves energy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com