Special sulfur crushing device

A crushing device and sulfur technology, applied in grain processing, etc., can solve problems such as life safety threats, safety hazards, and production stability, and achieve the effect of avoiding splashing and falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

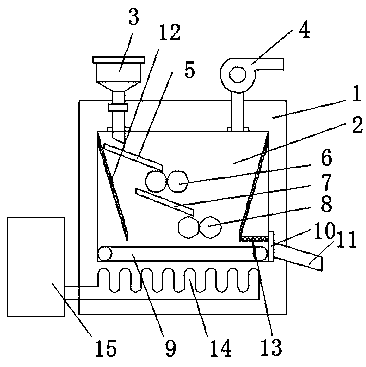

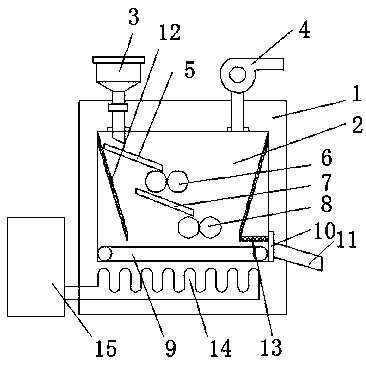

[0012] Such as figure 1 A special sulfur crushing device of the present invention includes an outer casing 1 and a crushing chamber 2, the crushing chamber 2 is arranged in the inner cavity of the outer casing 1, and the top of the outer casing 1 is arranged at the feeding material connected to the crushing chamber 2. Cavity 3 and vacuum pump 4, the crushing chamber 2 under the feeding chamber 3 is provided with a primary deflector 5, and a coarse crushing roller 6 is arranged under the primary deflector 5, and the coarse crushing roller 6 is connected to There is a secondary deflector 7, and a fine crushing roller 8 is arranged under the secondary deflector 7, and a delivery roller 9 is arranged under the fine crushing roller 8, and the delivery roller 9 is transported to the crushing chamber 2 A discharge port 10, the discharge port 10 is provided with a discharge pipe 11 connected to the outside of the outer shell 1, and the crushing chamber 2 is provided with a conical spl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com