Polymer coating mixing machine

A technology of mixers and polymers, applied in the direction of mixers, shaking/oscillating/vibrating mixers, mixer accessories, etc., can solve problems such as slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] as attached figure 1 to attach Figure 6 Shown:

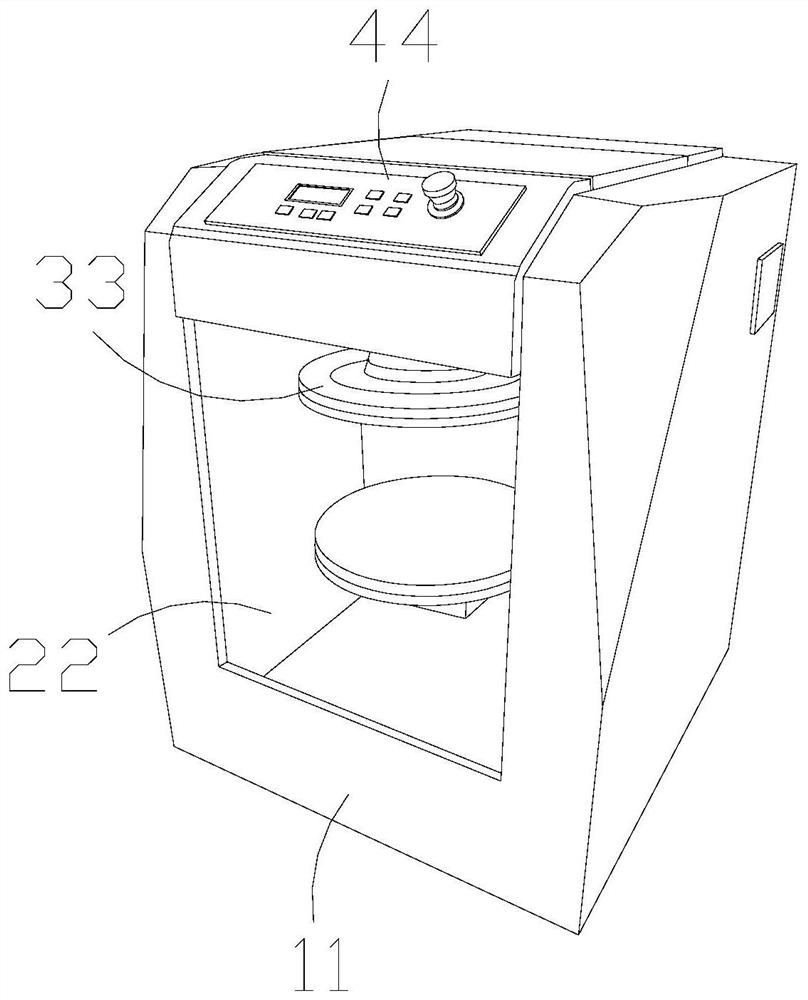

[0033] The present invention provides a polymer paint mixer, the structure of which includes a box body 11, an inner grid 22, a splint 33, and an operating panel 44, the inner grid 22 and the box body 11 are an integrated structure, and the splint 33 is installed on Inside the inner grid 22 , the operation panel 44 is welded to the outer surface of the box body 11 .

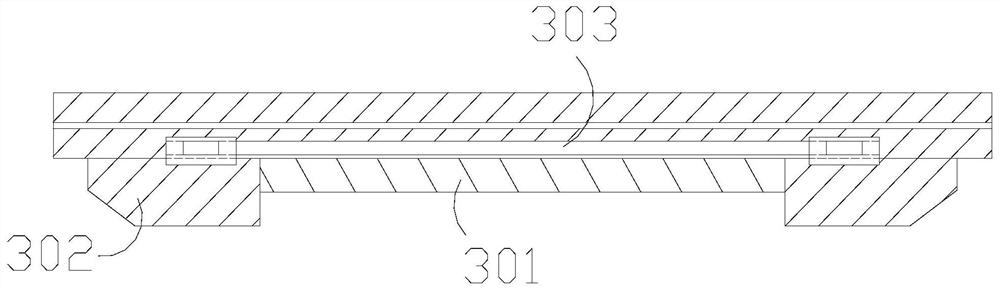

[0034] The splint 33 includes a middle rod 301, a support block 302, and an inner channel 303. Both ends of the middle rod 301 are installed between the two support blocks 302, and the top ends of the support block 302 are embedded in the inner channel 303 and are flexibly connected. .

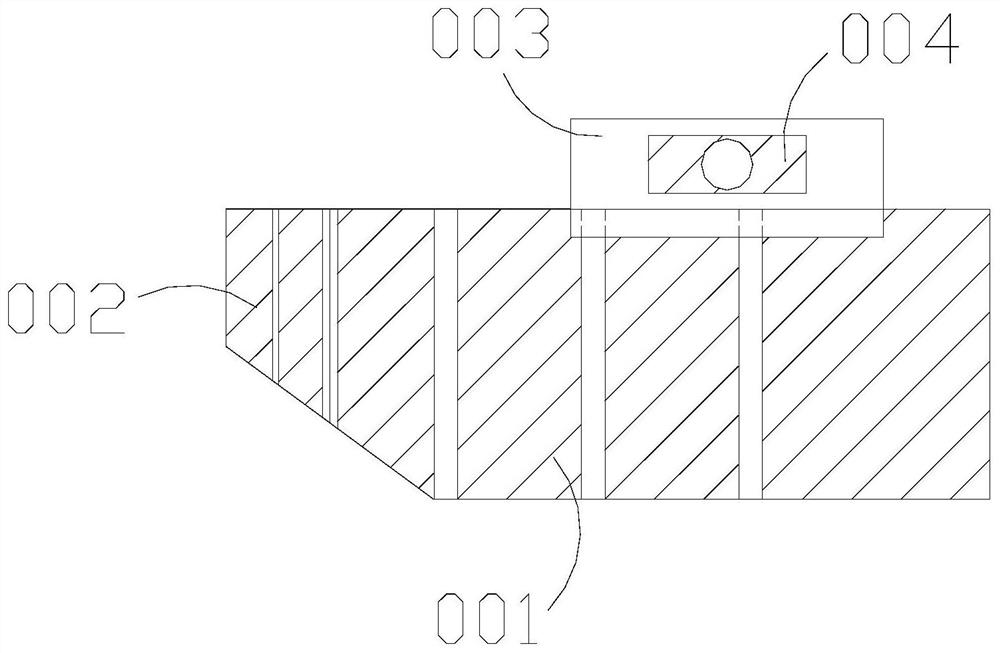

[0035] Wherein, the supporting block 302 includes a pushing block 001, a pressing block 002, an extending block 003, and a sliding block 004. The upper end is fixedly connected, the press block 002 is connected to the side of the push block 001, the press block 002 is a...

Embodiment 2

[0042] as attached Figure 7 to attach Figure 9 Shown:

[0043] Wherein, the middle pole 301 includes a spacer w11, a spacer bar w12, and a rubber support block w13, the spacer w11 is fixed on the outer surface of the rubber support block w13, and the spacer w12 is attached to the outer surface of the rubber support block w13, The support rubber block w13 has a trapezoidal structure. The support rubber block w13 has its own toughness, and when the force on both sides is stressed, it plays the role of extrusion force. The spacer w12 separates the force-bearing part from the fixed parts.

[0044]Wherein, the supporting rubber block w13 includes a pressing arc 111, an insulating strip 112, and an outer limit layer 113. The insulating strip 112 is attached to the outer surface of the pressing arc 111, and the end of the insulating bar 112 is far away from the pressing arc 111. Connected with the outer limit layer 113, the force barrier bar 112 has an arc-shaped structure, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com