Multidirectional pressing device

A pressing device and multi-directional technology, applied in the field of pressing devices, can solve the problems of complex structure and troublesome operation of positioning fixtures, and achieve the effects of simple structure, convenient operation and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

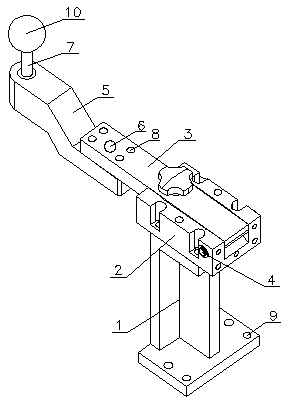

[0013] A multi-directional pressing device, including a support 1, a U-shaped seat 2 and a turning plate 3, the U-shaped seat 2 is fixedly installed on the upper end of the support 1, and the rear end of the turning plate 3 is located in the U-shaped seat 2 and passes through the pin shaft 4 It is rotatably connected with the two side walls of the U-shaped seat 2. The front end of the flip plate 3 is provided with a transition plate 5. The transition plate 5 is horizontally connected with the flip plate 3 through the rotating shaft 6. The front end of the transition plate 5 is provided with a threaded hole, and the threaded hole is internally threaded. A pressing bar 7 is connected, and a positioning pin 8 connected with the turnover plate 3 is provided at the rear end of the transition plate 5 .

[0014] As a further improvement of the above technical solution, the support 1 is an I-shaped structure, and both sides of the U-shaped seat 2 are connected to the upper end of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com