A stainless steel surface drawing treatment auxiliary device

A surface drawing and auxiliary device technology, which is applied in the direction of metal processing equipment, abrasive belt grinders, manufacturing tools, etc., can solve the problems of the influence of the service life of the drawing belt, increase the use cost of the drawing belt, and shorten the cooling time of the drawing belt. The effect of drawing cost, prolonging the service life and reducing the risk of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

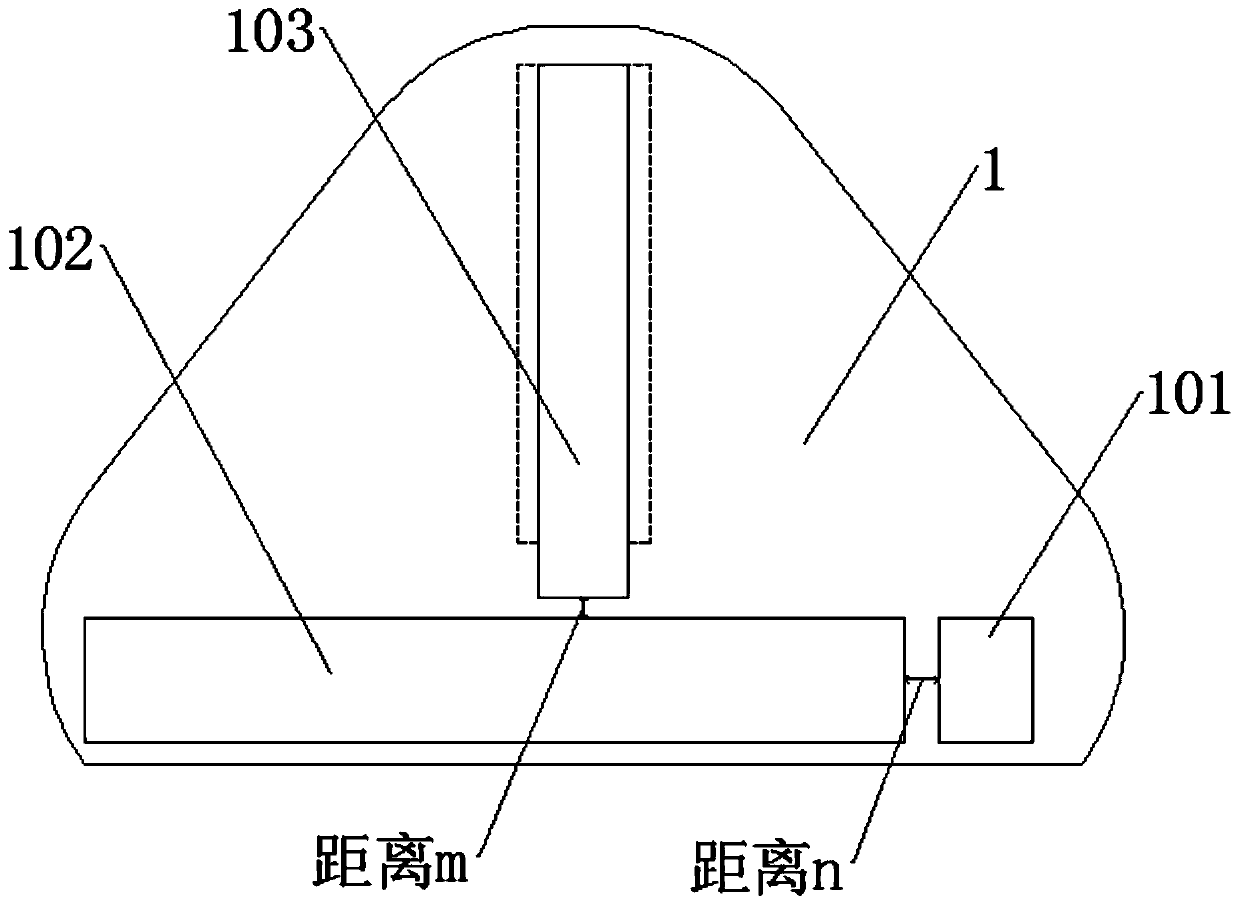

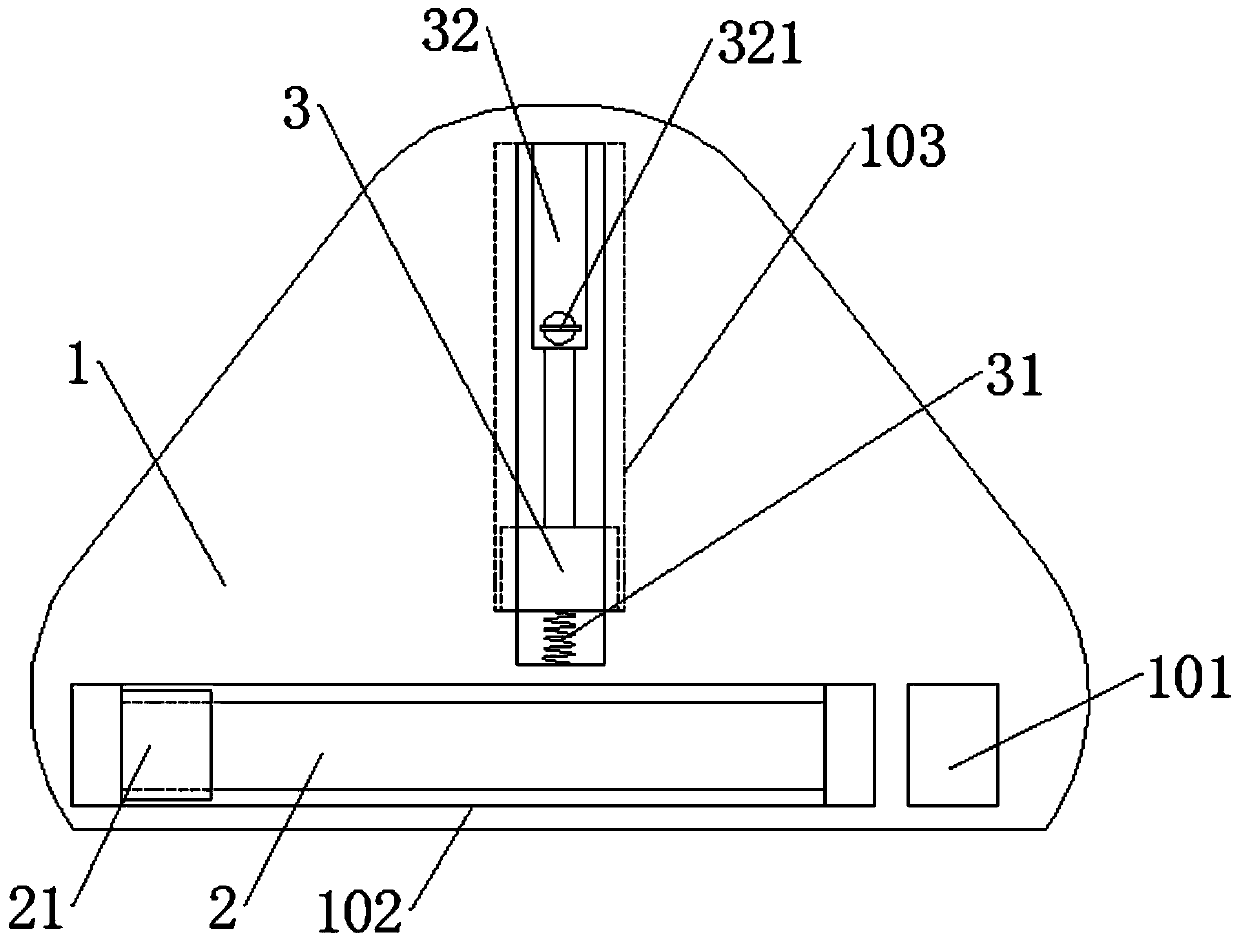

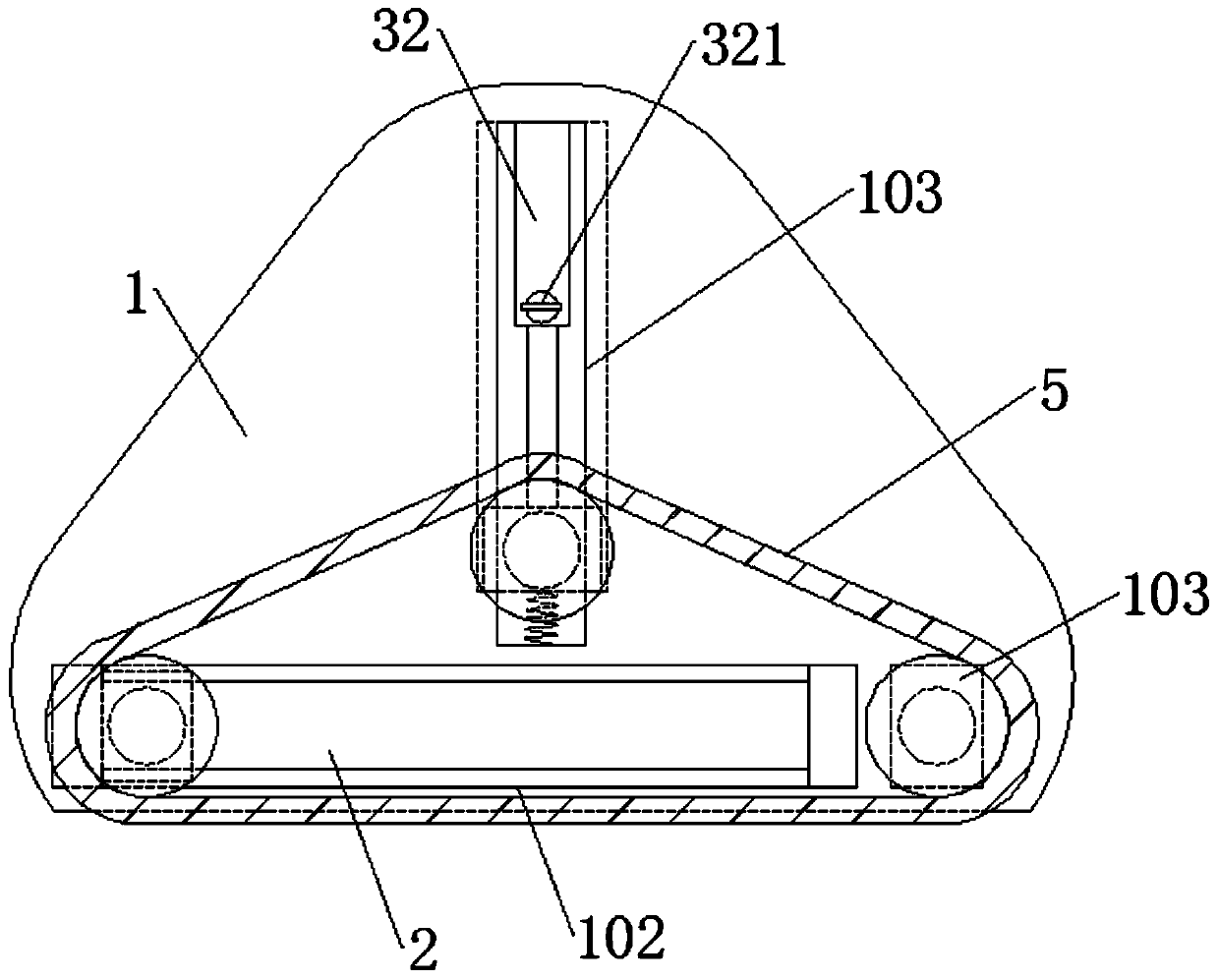

[0039] see Figure 1-6 , an auxiliary device for stainless steel surface drawing treatment, comprising a fixed bottom plate 1, the front end of the fixed bottom plate 1 is respectively excavated with a fixed groove 101, a movable horizontal groove 102 and a movable vertical groove 103, the fixed groove 101 and the movable horizontal groove 102 are arranged in parallel, and the movable horizontal groove 102 is arranged in parallel. Slot 102 and movable vertical groove 103 are arranged vertically, and electric slide table 2 is connected in movable horizontal groove 102, and slide block 21 is slidably connected on electric slide table 2, and movable block 3 is slidably connected in movable vertical groove 103, and movable block 3 and The inner top end of movable vertical groove 103 is connected with expansion link 32, is connected with locking knob 321 on the expansion link 32, and locking knob 321 is used for fixing the length of expansion link 32, and the inner end of fixing gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com